Ultrasonic detection device for uranium-based alloy fuel pellets

A technology for fuel pellets and ultrasonic testing, which is applied in measurement devices, material analysis using sonic/ultrasonic/infrasonic waves, and material analysis, etc., can solve the problems of difficulty in meeting modern production testing, low degree of digitization, and small scope of application, and achieves Improve system applicability, improve detection efficiency, and have a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

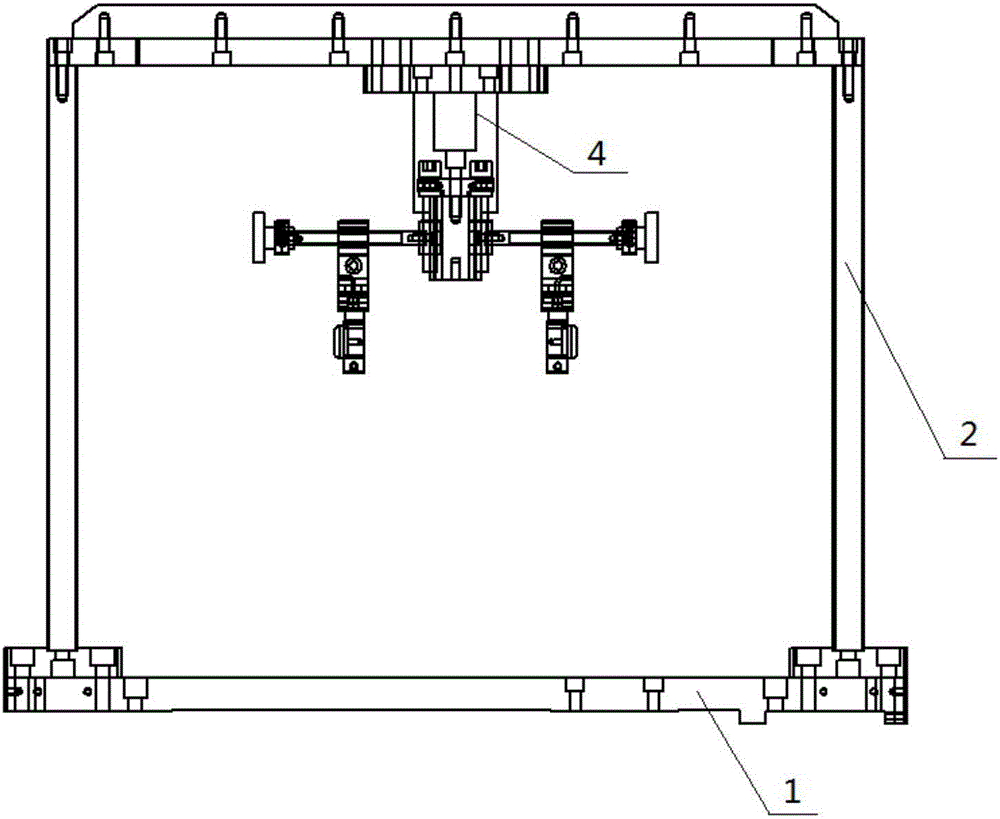

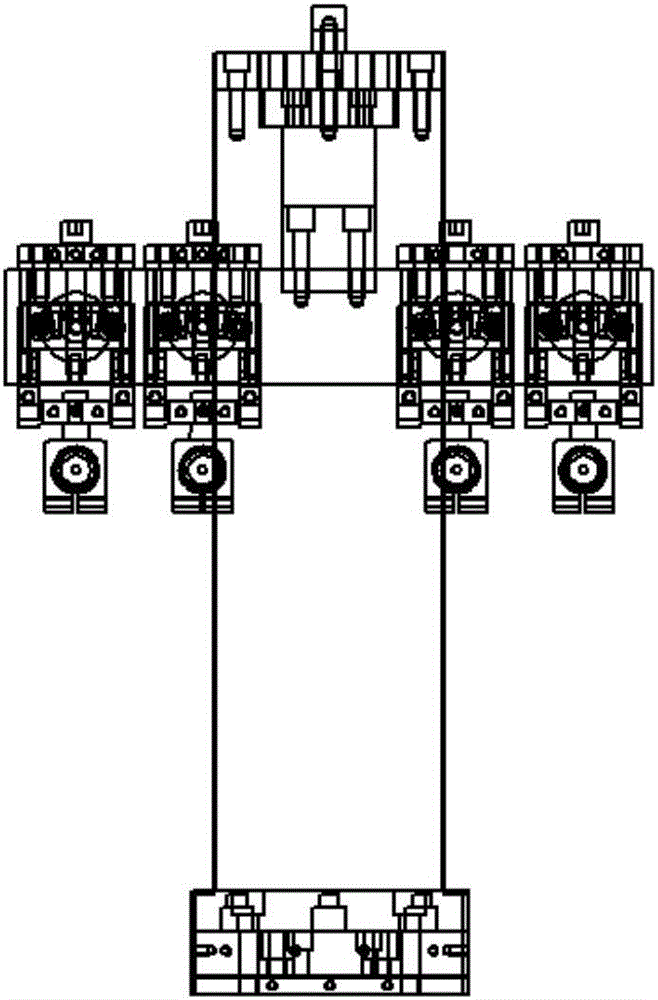

[0056] Such as Figure 1-3 The ultrasonic testing device for uranium-based alloy fuel pellets shown includes an eight-channel probe adjustment device, tail top assembly, drogue assembly, portal frame, compression spring, guide rail, base, motor, portal frame motor, and taper sleeve motor.

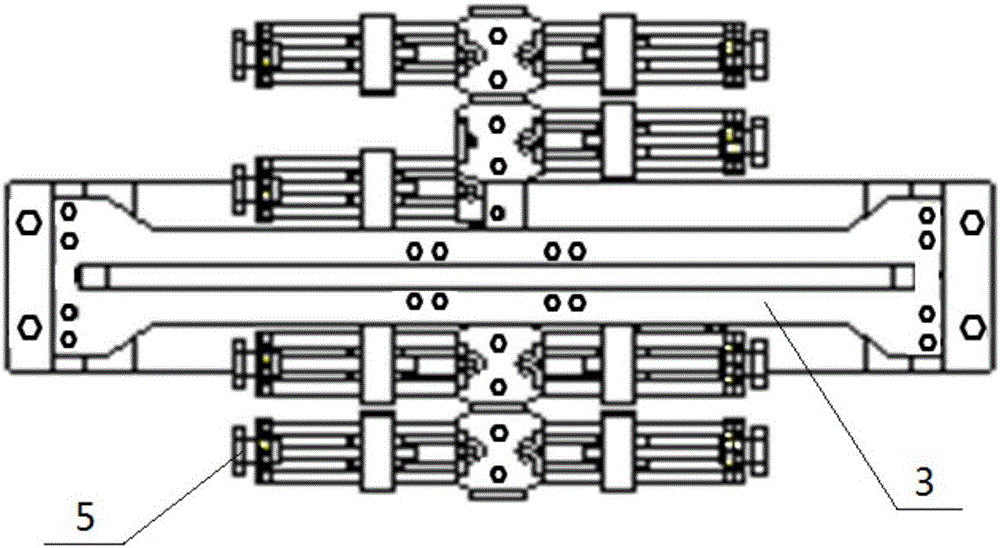

[0057] The eight-channel probe adjustment device includes a bottom plate 1 , a side plate 2 , a top plate 3 , a connector 4 and a probe hanger assembly 5 .

[0058] The bottom plate 1, side plate 2 and top plate 3 are used to fix the probe adjustment device and are made of 45# steel. The connector 4 and the probe hanger assembly 5 are made of 304 stainless steel because they need to be soaked in water for a long time.

[0059] The bottom plate 1, the side plate 2 and the top plate 3 are all elongated thin plates.

[0060] The bottom plate 1 inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com