Thermally Induced Ultra-Large Mode Field Fiber

A super-large, mode field technology, applied in the field of lasers, can solve the problems of limited reduction of core numerical aperture, increase of fiber core diameter, and difficulty in manufacturing, and achieve the goal of reducing manufacturing difficulty, reducing numerical aperture, and improving refractive index benchmarks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

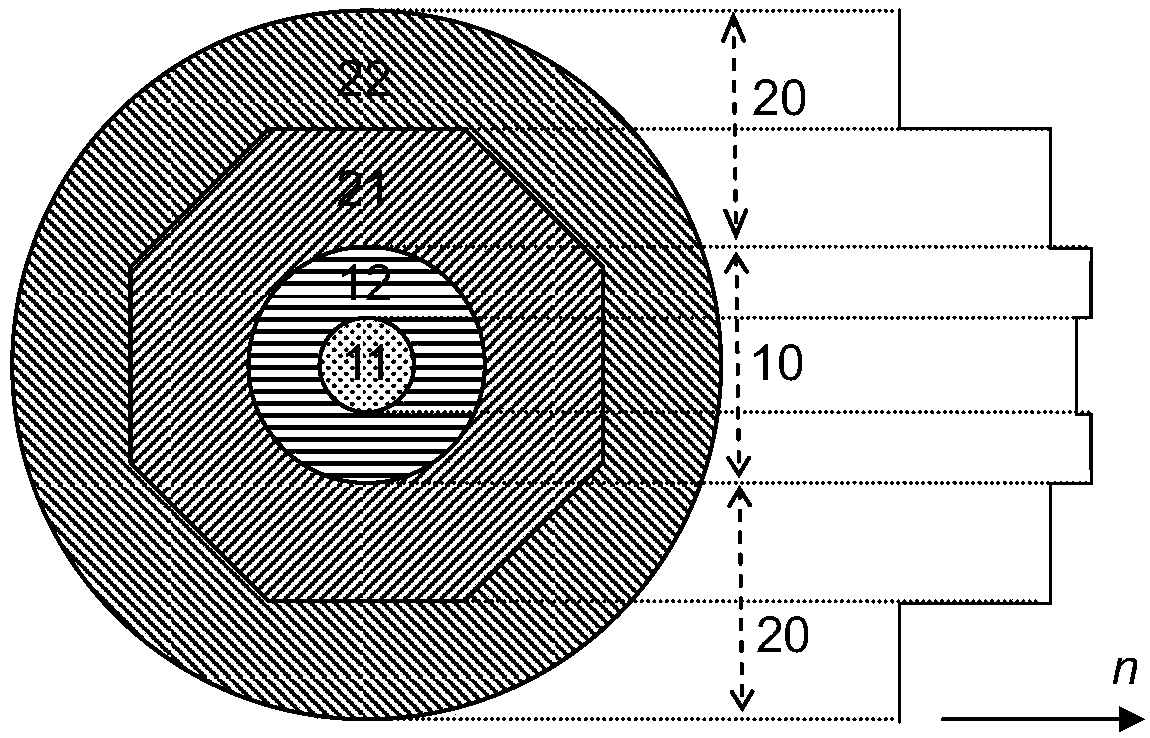

[0025] image 3 An embodiment of the present invention is given (corresponding to the 37th embodiment in Table 1), the arrow indicates the positive direction of the refractive index n, and the solid line on the right indicates the distribution of the refractive index. The inner fiber core 11 that this embodiment selects has a diameter of 30 microns, and the gain medium doped in the inner fiber core 11 is erbium ion and ytterbium ion, and the diameter of the outer fiber core 12 is 150 microns, and the refractive index of the outer fiber core 12 is the same as that of the inner fiber core. The refractive indices of the cores 11 are equal. The inner cladding 21 adopts a regular hexagonal structure, and the diameter of the inscribed circle is 400 microns, and the numerical aperture of the outer core 12 relative to the inner cladding 21 is 0.1. The outer cladding layer 22 is circular, and the numerical aperture of the inner cladding layer 21 relative to the outer cladding layer 22...

Embodiment 2

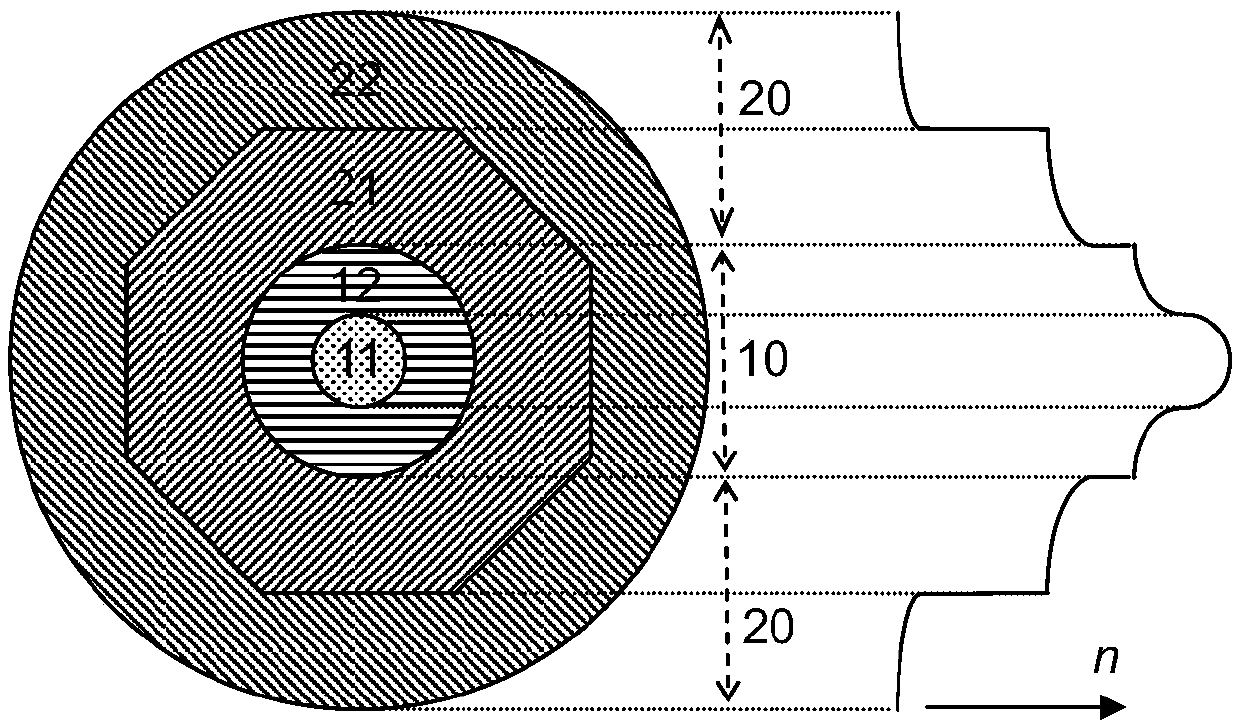

[0028] Figure 4 Another embodiment of the present invention (corresponding to the 527th embodiment of Table 1) is provided. The diameter of the inner fiber core 11 selected in this embodiment is 50 microns, and the gain medium doped in the inner fiber core 11 is ytterbium ions. The diameter of the outer core 12 is 125 microns, and the refractive index of the outer core 12 is smaller than that of the inner core 11, and the difference between the two is 0.00005. The inner cladding 21 adopts a regular octagonal structure, and the diameter of the inscribed circle is 250 microns, and the numerical aperture of the inner cladding 21 relative to the outer core 12 is 0.15. A multimode optical fiber 23 is included in the outer cladding 22 . The multimode optical fiber 23 has a circular core with a diameter of 250 microns and is in optical contact with the inner cladding 21 . The outer cladding layer 22 is circular, and the numerical aperture of the inner cladding layer 21 relative to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com