Preparation method of local three-dimensional microstructure optical fiber

A microstructure optical fiber, three-dimensional technology, applied in glass manufacturing equipment, coupling of optical waveguides, optics, etc., can solve the problems of complicated preparation process, affecting the popularization and use of three-dimensional structured optical fiber, high production cost, etc., and achieves low refractive index. , the effect of low numerical aperture and mode instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

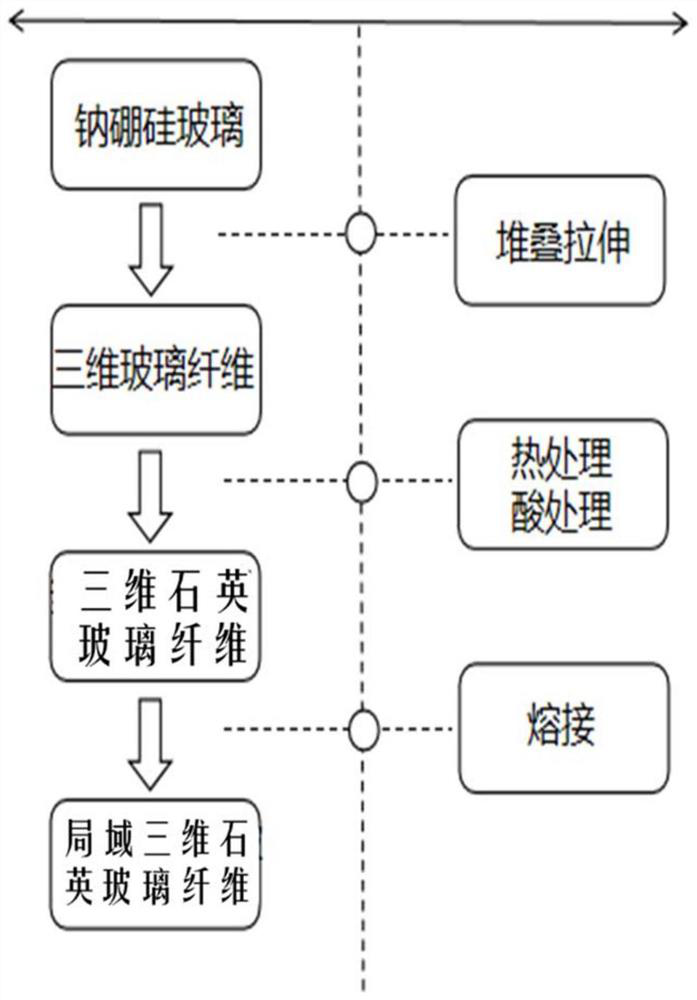

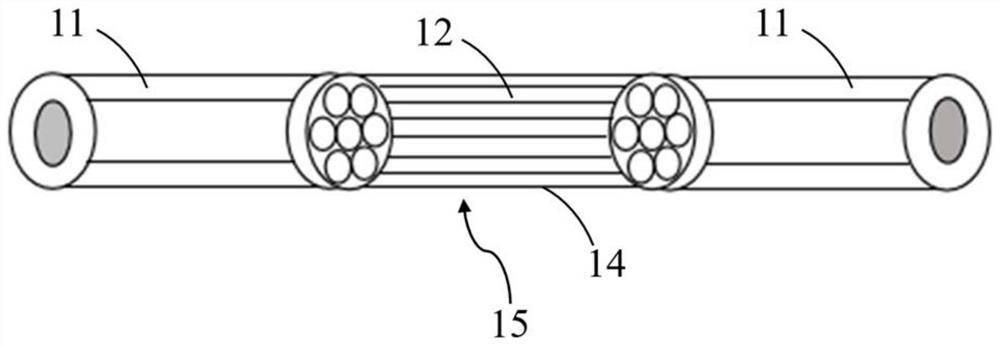

[0037] See figure 1 and figure 2 as shown, figure 1 A flowchart of a method for preparing a local three-dimensional microstructured optical fiber provided by an embodiment of the present invention; figure 2 Schematic diagram of the localized three-dimensional microstructured optical fiber provided for this example. The method provided in this embodiment aims to reduce the process complexity of preparing glass fibers into optical fibers with three-dimensional structures, and to make the optical fibers with three-dimensional microstructures prepared in various forms. The preparation method of the local three-dimensional microstructure optical fiber provided in this embodiment includes the following steps:

[0038] S1, preparation of sodium borosilicate glass rod: 10 parts by weight of high-purity raw material GeNO 3 , 56 parts by weight of Na 2 CO 3 , 26 parts by weight of H 3 BO 3 and 8 parts by weight of SiO 2 After mixing evenly, pour it into a platinum crucible, m...

Embodiment 2

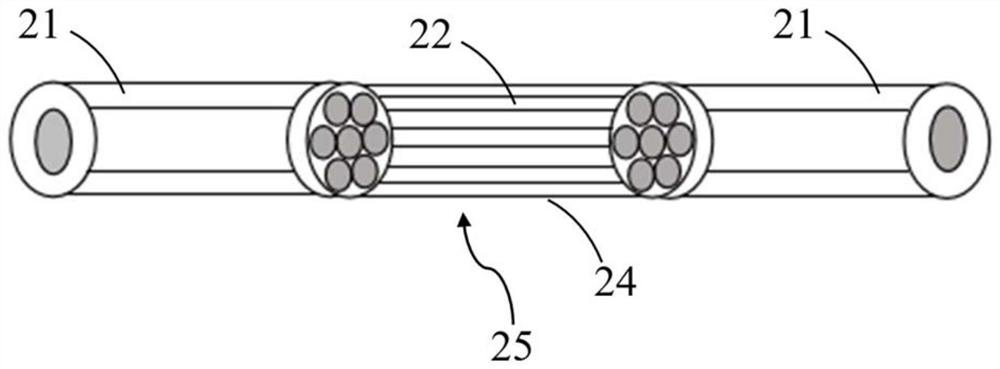

[0045] See figure 1 and image 3 as shown, figure 1 A flowchart of a method for preparing a local three-dimensional microstructured optical fiber provided by an embodiment of the present invention; image 3 Schematic diagram of the localized three-dimensional microstructured optical fiber provided for this example. The method provided in this embodiment aims to reduce the process complexity of preparing glass fibers into optical fibers with three-dimensional structures, and to make the optical fibers with three-dimensional microstructures prepared in various forms. The preparation method of the local three-dimensional microstructure optical fiber provided in this embodiment includes the following steps:

[0046] S1, preparation of sodium borosilicate glass rod: 5 parts by weight of high-purity raw material GeNO 3 , 61 parts by weight of Na 2 CO 3 , 31 parts by weight of H 3 BO 3 and 3 parts by weight of SiO 2 After mixing evenly, pour it into a platinum crucible, melt...

Embodiment 3

[0051] See figure 1 and Figure 4 as shown, figure 1 A flowchart of a method for preparing a local three-dimensional microstructured optical fiber provided by an embodiment of the present invention; Figure 4 Schematic diagram of the localized three-dimensional microstructured optical fiber provided for this example. The method provided in this embodiment aims to reduce the process complexity of preparing glass fibers into optical fibers with three-dimensional structures, and to make the optical fibers with three-dimensional microstructures prepared in various forms. The preparation method of the local three-dimensional microstructure optical fiber provided in this embodiment includes the following steps:

[0052] S1, preparation of sodium borosilicate glass rod: 15 parts by weight of high-purity raw material GeNO 3 , 51 parts by weight of Na 2 CO 3 , 21 parts by weight of H 3 BO 3 and 13 parts by weight of SiO 2 After mixing evenly, pour it into a platinum crucible, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com