Exposure method, condensing lens and exposure machine

A technology of condensing lens and exposure method, which is applied in the fields of optomechanical equipment, microlithography exposure equipment, photolithography process exposure device, etc., can solve the problems of difficult imaging of glass substrates, small depth of focus, etc., and increase the stability of mass production. , reduce the numerical aperture, optimize the effect of the exposed image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

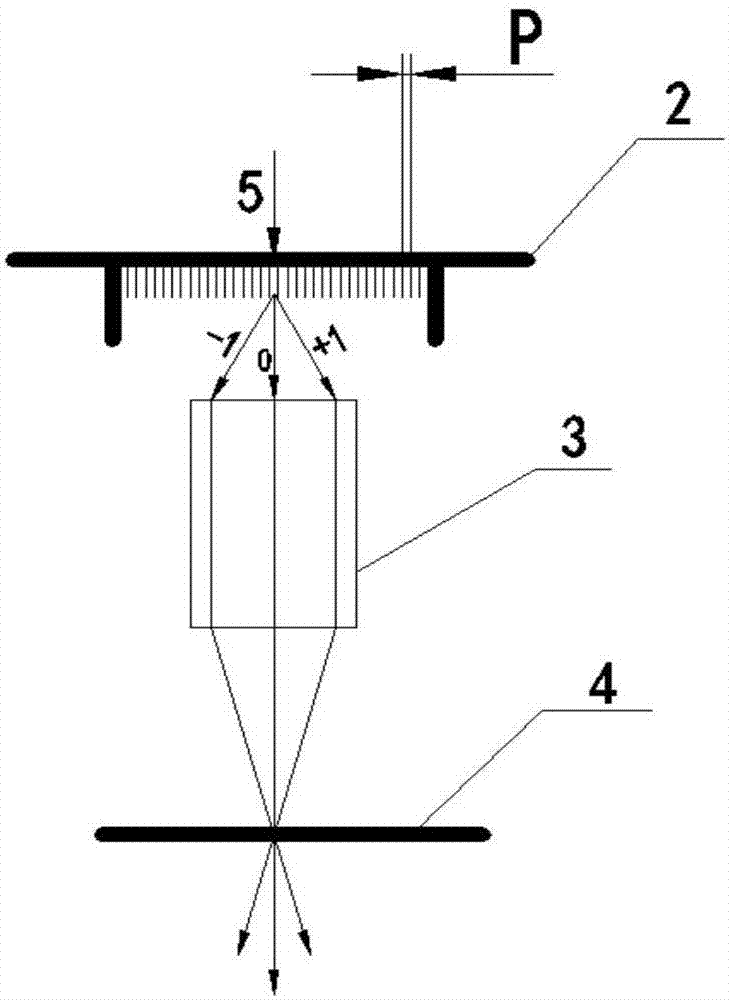

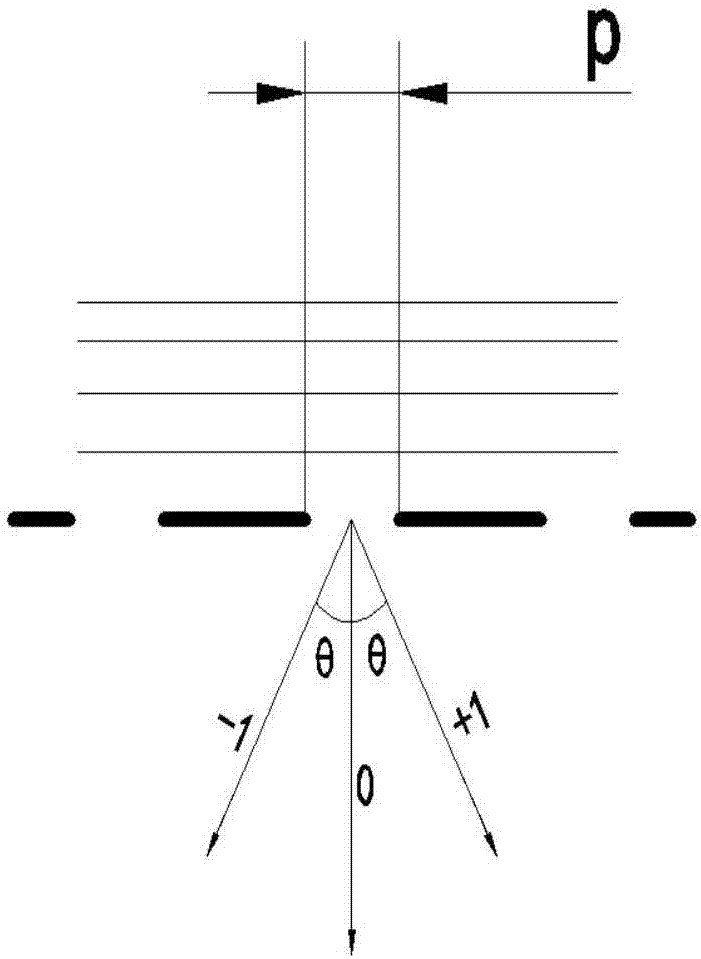

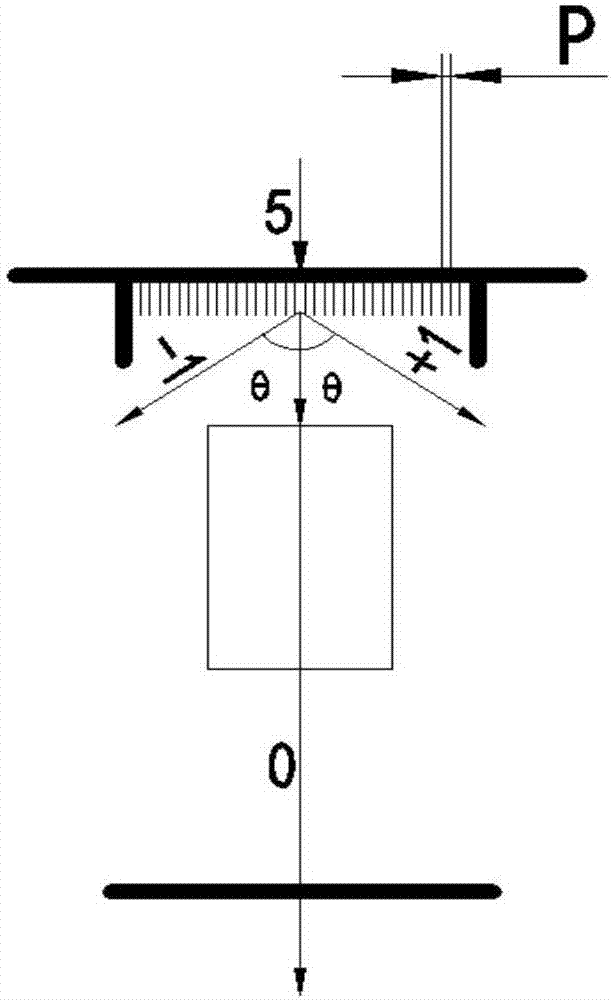

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

[0039] The present embodiment provides an exposure method to improve the imaging depth of focus, and the imaging depth of focus is closely related to the numerical aperture of the condenser lens, and its mathematical relationship is as follows:

[0040]

[0041] In formula (2), DOF is imaging depth of focus; k 2 λ is the process factor; λ is the wavelength of light; NA is the numerical aperture.

[0042] Usually process factor k 2 and the light wavelength λ are constants. It can be seen from formula (2) that when the numerical aperture NA decreases, the imaging depth of focus DOF will increase. The production process of the TFT exposure part is that after the glass substrate is coated with photoresist, it is dried under reduced pressure to remove most of the solvent in the photoresist. Define the graphics; finally display the graphics through the development pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com