Emulsified skincare cosmetic teaching training device and control method thereof

A control method and cosmetic technology, applied in teaching models, educational appliances, instruments, etc., can solve the problems of small processing capacity, increased safety factors, and large processing capacity, and achieve the effect of prolonging service life, improving learning interest, and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0043] Example 1 prepares the cream

[0044] Raw material formula table

[0045]

[0046] Operation method:

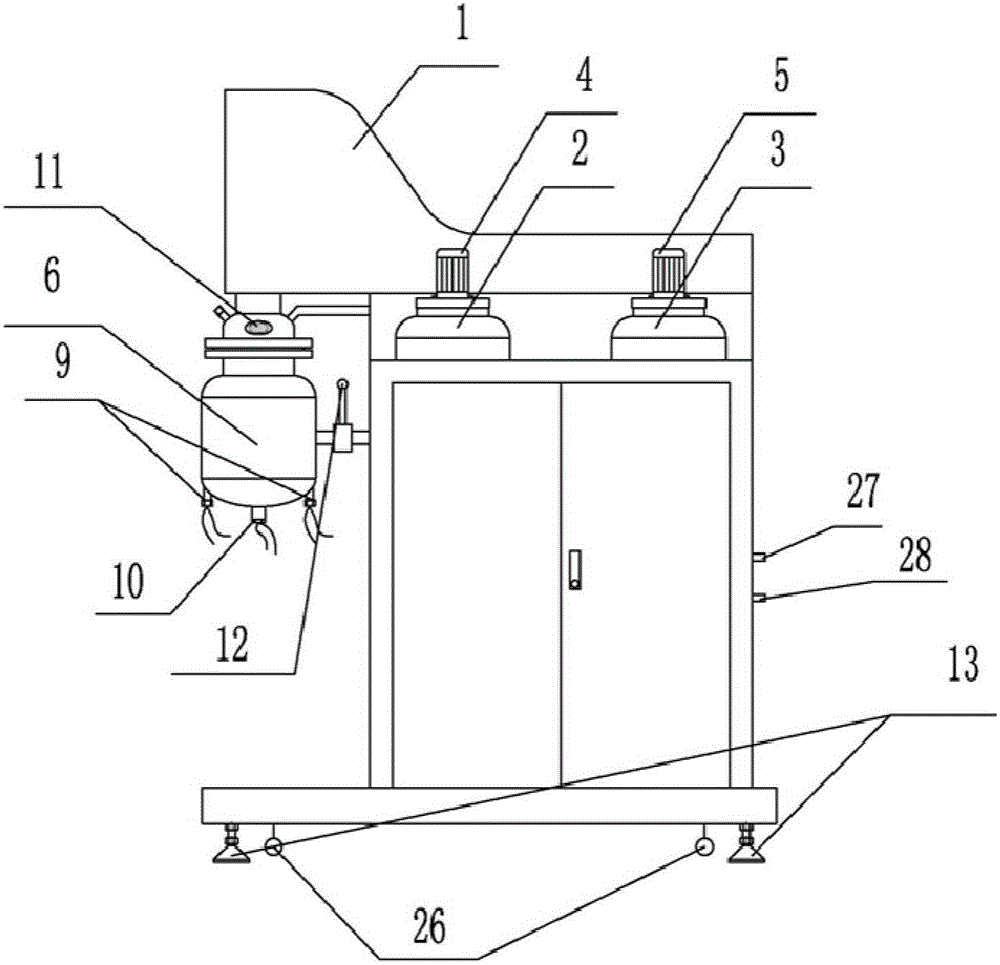

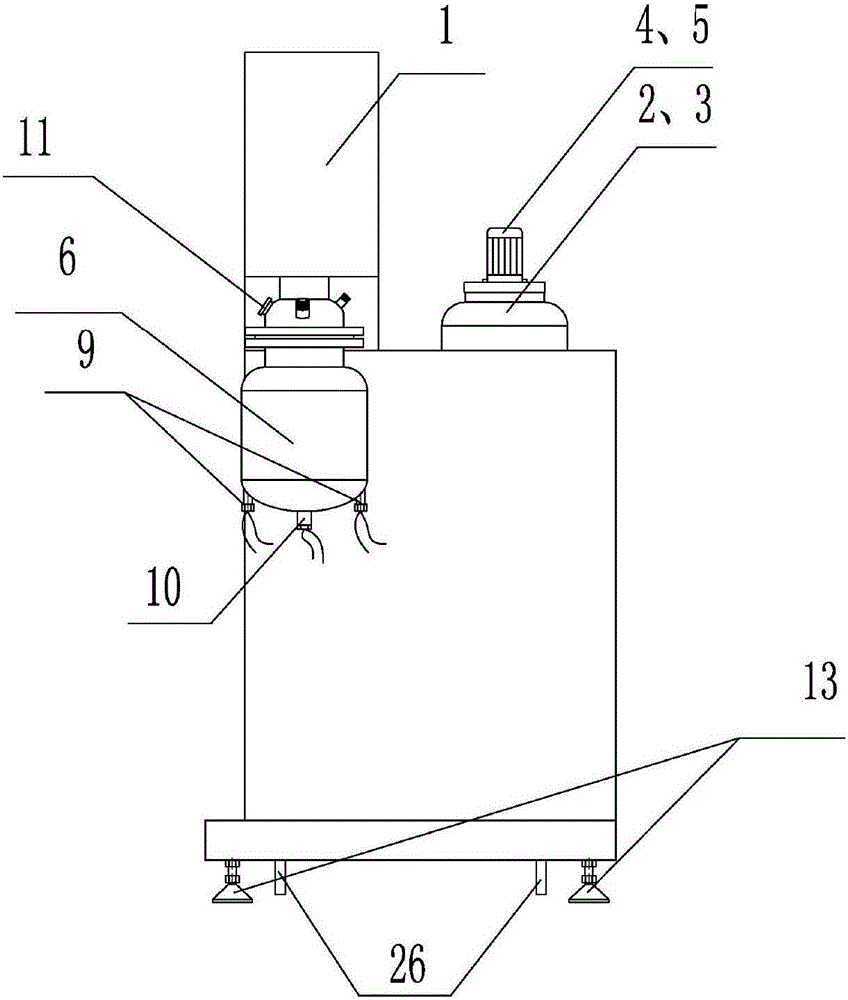

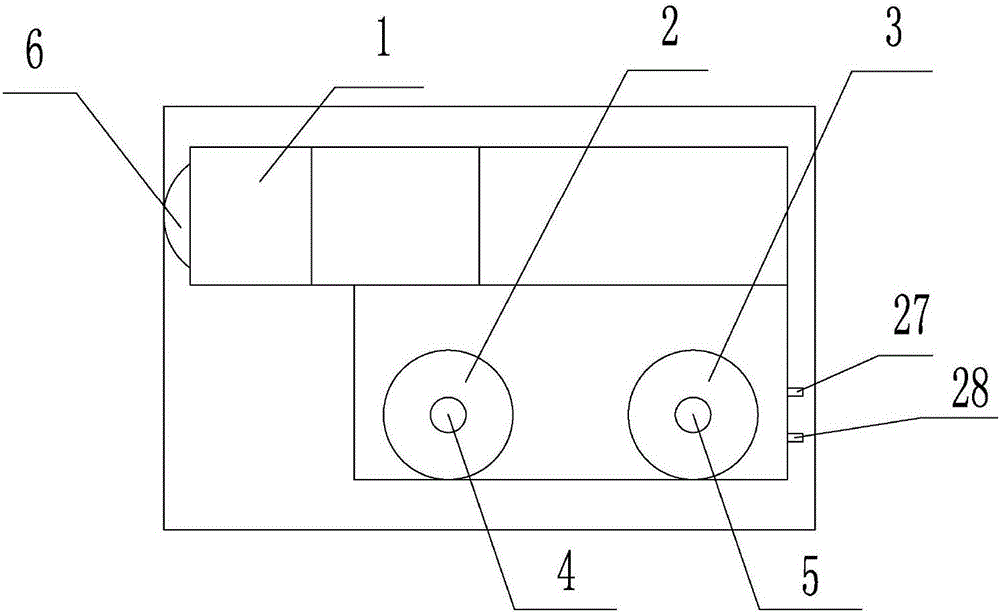

[0047] Weigh the substances of Phase A and Phase B according to the formula, send power to the device, start the host computer, and enter the control interface. After cleaning the water phase pot 2 with deionized water, add the components of component B (water phase) into the water phase pot 2 in sequence, and turn on the electric heating button of the water phase pot 2 on the control interface of the host computer to set the water phase pot The temperature is 90° C., and the stirring motor 4 of the water phase pot is turned on.

[0048] After cleaning the oil phase pot 3, add the components of component A (oil phase) into the oil phase pot 3 in turn, and turn on the electric heating button of the oil phase pot 3 on the control interface of the host computer, and set the temperature of the oil phase pot to 85°C , Turn on the stirring motor 5 of the oil phase pot....

example 2

[0054] Example 2 Preparation of night cream

[0055] Raw material formula table

[0056]

[0057]

[0058] Operation method:

[0059] Weigh the substances of Phase A and Phase B according to the formula, send power to the device, start the host computer, and enter the control interface.

[0060] After cleaning the water phase pot 2 with deionized water, add the components of component B (water phase) into the water phase pot 2 in sequence, and turn on the electric heating button of the water phase pot 2 on the control interface of the host computer to set the water phase pot The temperature is 90° C., and the stirring motor 4 of the water phase pot is turned on.

[0061] After cleaning the oil phase pot 3, add the components of component A (oil phase) into the oil phase pot 3 in turn, and turn on the electric heating button of the oil phase pot 3 on the control interface of the host computer, and set the temperature of the oil phase pot to 85°C , Turn on the stirring ...

example 3

[0067] Example 3 prepares skin care gel

[0068] Raw material formula table

[0069]

[0070]

[0071] Operation method:

[0072] Weigh the substances of phases A, B, C, D, and E according to the formula, supply power to the device, start the upper computer, and enter the control interface. After cleaning the water phase pot 2 with deionized water, add the components of component A (water phase) into the water phase pot 2 in sequence, and turn on the electric heating button of the water phase pot 2 on the control interface of the host computer to set the water phase pot The temperature is 30°C, and the stirring motor 4 of the water phase pot is turned on.

[0073] Clean the emulsification pot 6, turn on the vacuum pump 17 on the host computer control interface, and when the vacuum degree is close to -1MPa, turn on the water phase pot discharge solenoid valve 19 to suck the water phase material into the emulsification pot 6. After sucking the material, close the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com