Insulated wire

A technology of insulated wires and metal cores, applied in insulated cables, insulators, insulated conductors, etc., can solve the problems of loss of insulation performance of insulating rubber, potential safety hazards, poor weather resistance of insulating rubber, etc., to improve insulation performance and corrosion resistance. performance, improved abrasion and weather resistance, enhanced strength and abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

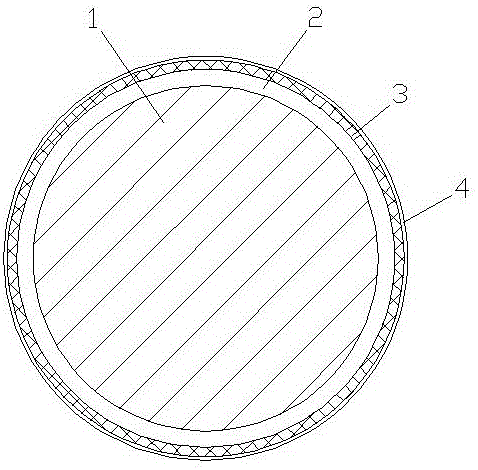

[0042] As shown in the figure, an insulated wire includes a metal core 1 and a protective layer wrapped around the outer layer of the metal core 1. The protective layer is an insulating rubber layer 2, a polyurethane fiber layer 3 and an insulating varnish layer from the inside to the outside. 4. The polyurethane fiber layer 3 is a polyurethane fiber cloth woven from polyurethane fibers.

[0043] The above is the basic implementation of this embodiment, further optimization, improvement and limitation can be done on the basis of the above:

[0044] For example, according to weight ratio, the insulating rubber layer 2 is mixed at 60°C by 36 parts of mixed rubber matrix, 4 parts of reinforcing fiber, 2 parts of vulcanizing agent, 4 parts of additive and 2 parts of filler. Among them, the mixed rubber matrix is obtained by mixing ethylene-propylene rubber, fluororubber, silicone rubber and asphalt in a weight ratio of 8:4:2:1, and the reinforcing fiber is made of polyurethane f...

Embodiment 2

[0059] As shown in the figure, an insulated wire includes a metal core 1 and a protective layer wrapped around the outer layer of the metal core 1. The protective layer is an insulating rubber layer 2, a polyurethane fiber layer 3 and an insulating varnish layer from the inside to the outside. 4. The polyurethane fiber layer 3 is a polyurethane fiber cloth woven from polyurethane fibers.

[0060] The above is the basic implementation of this embodiment, further optimization, improvement and limitation can be done on the basis of the above:

[0061] For example, according to weight ratio, the insulating rubber layer 2 is mixed at 80°C by 38 parts of mixed rubber matrix, 6 parts of reinforcing fiber, 3 parts of vulcanizing agent, 5 parts of admixture and 3 parts of filler. Among them, the mixed rubber matrix is obtained by mixing ethylene-propylene rubber, fluororubber, silicone rubber and asphalt at a weight ratio of 10:5:3:1, and the reinforcing fiber is made of polyurethane...

Embodiment 3

[0076] As shown in the figure, an insulated wire includes a metal core 1 and a protective layer wrapped around the outer layer of the metal core 1. The protective layer is an insulating rubber layer 2, a polyurethane fiber layer 3 and an insulating varnish layer from the inside to the outside. 4. The polyurethane fiber layer 3 is a polyurethane fiber cloth woven from polyurethane fibers.

[0077] The above is the basic implementation of this embodiment, further optimization, improvement and limitation can be done on the basis of the above:

[0078] For example, according to weight ratio, the insulating rubber layer 2 is mixed at 70°C by 37 parts of mixed rubber matrix, 5 parts of reinforcing fiber, 2.5 parts of vulcanizing agent, 4.5 parts of admixture and 2.5 parts of filler. Among them, the mixed rubber matrix is obtained by mixing ethylene-propylene rubber, fluororubber, silicone rubber and asphalt at a weight ratio of 9:4.5:2.5:1, and the reinforcing fiber is made of pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com