Foam metal-based multi-porous-channel IPMC electrically driven material and preparation method therefor

An electric actuation material, metal foam technology, applied in the material selection of piezoelectric devices or electrostrictive devices, the manufacture/assembly of piezoelectric/electrostrictive devices, the selection of device materials, etc., can solve the problem of hindering ion Liquid migration and other issues, to achieve the effect of wide frequency response range and stable output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

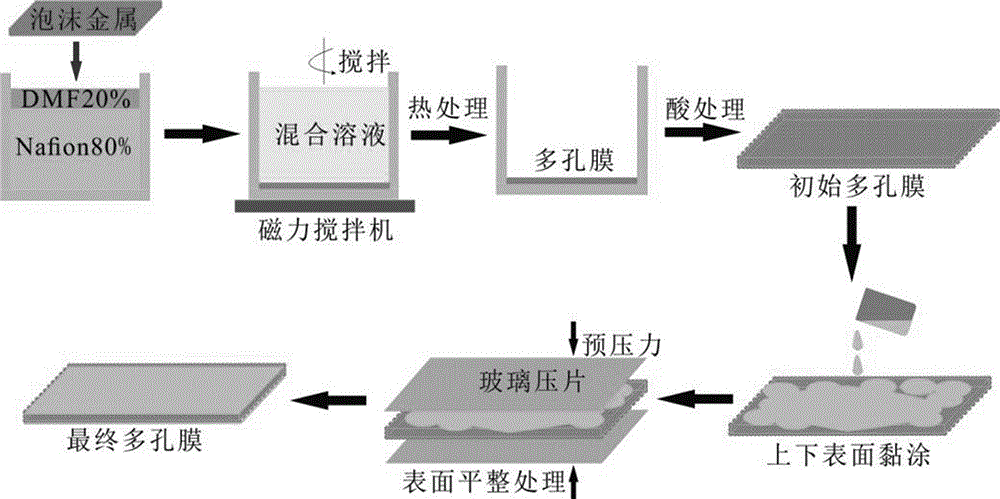

[0034] The preparation steps of the porous metal-based IPMC electro-actuated material are as follows: figure 1 As shown, the details are as follows:

[0035] (1) Preparation of foam metal copper embedded Nafion membrane:

[0036] Pour 16 ml Nafion solution and 4 ml dimethylformamide (DMF) into the casting mold. The purpose of adding DMF is to slow down the volatilization of the solvent, thereby preventing Nafion from cracking during the solidification process; then mix the solution with a magnetic stirrer Stir to make the solution evenly mixed, and ultrasonically oscillate to remove the bubbles in the solution; then, put the foam metal copper into the casting mold, and put the casting mold into a constant temperature drying oven to heat: first, the solution is heated at 70 °C for 48 h to evaporate to form a thin film , and then the temperature was raised continuously to increase the rigidity of the film, and finally annealed at 150 °C for 8 minutes to remove the residual stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com