Lithium iron phosphate and preparation method thereof

A technology of lithium iron phosphate and iron source, applied in the field of lithium iron phosphate and its preparation, can solve the problems of poor diffusion rate of lithium ions and poor conductivity of lithium iron phosphate, etc., to solve insufficient power density, improve conductivity and ion diffusion The effect of high rate and high rate charge and discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

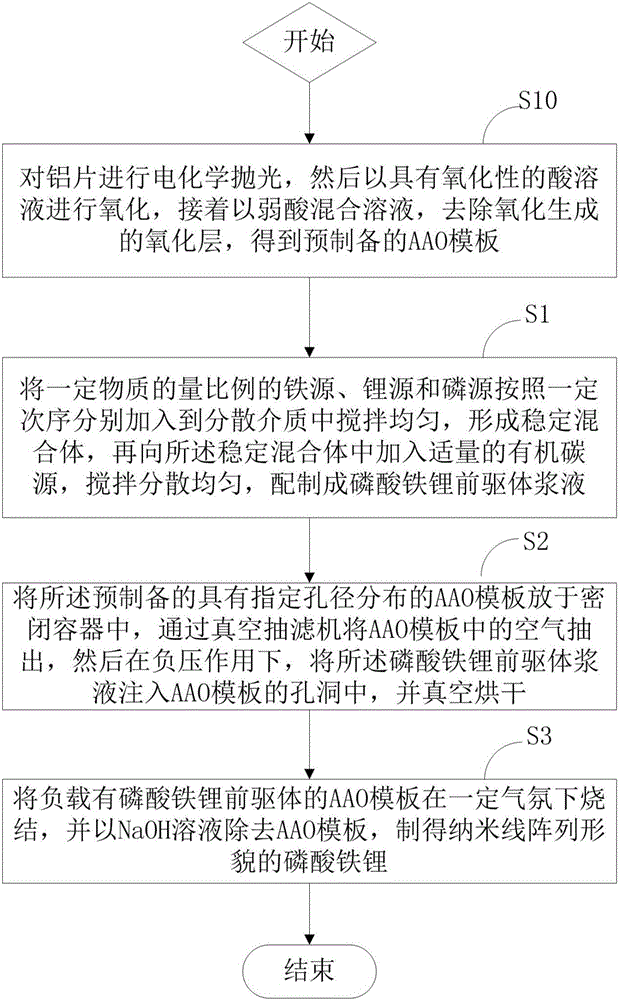

[0030] refer to figure 1 , the embodiment of the present invention proposes a preparation method of lithium iron phosphate, comprising:

[0031] S1: Add the iron source, lithium source and phosphorus source in a certain proportion to the dispersion medium in a certain order and stir evenly to form a stable mixture, then add an appropriate amount of organic carbon source to the stable mixture, and stir Disperse evenly and prepare lithium iron phosphate precursor slurry;

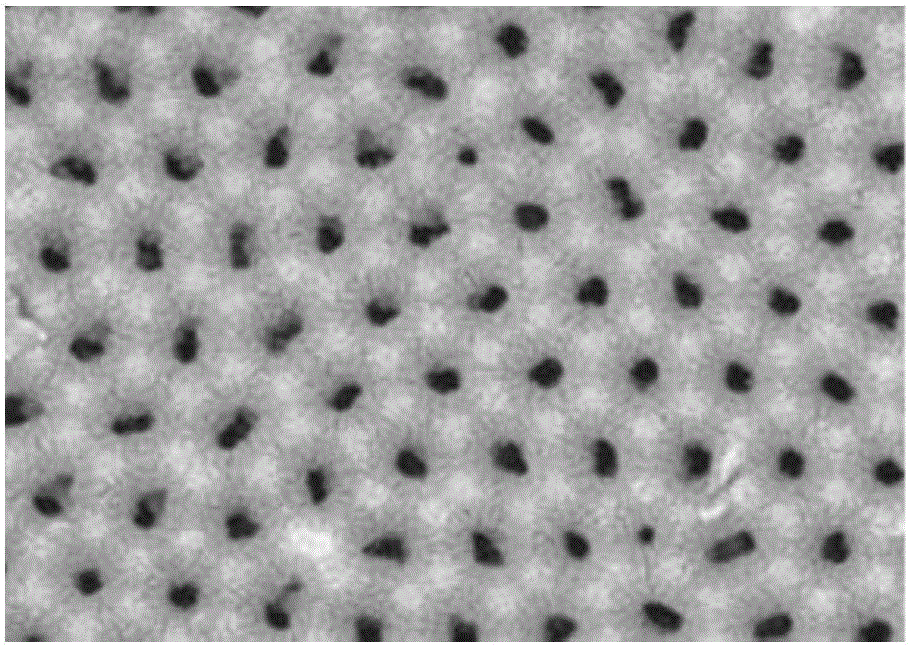

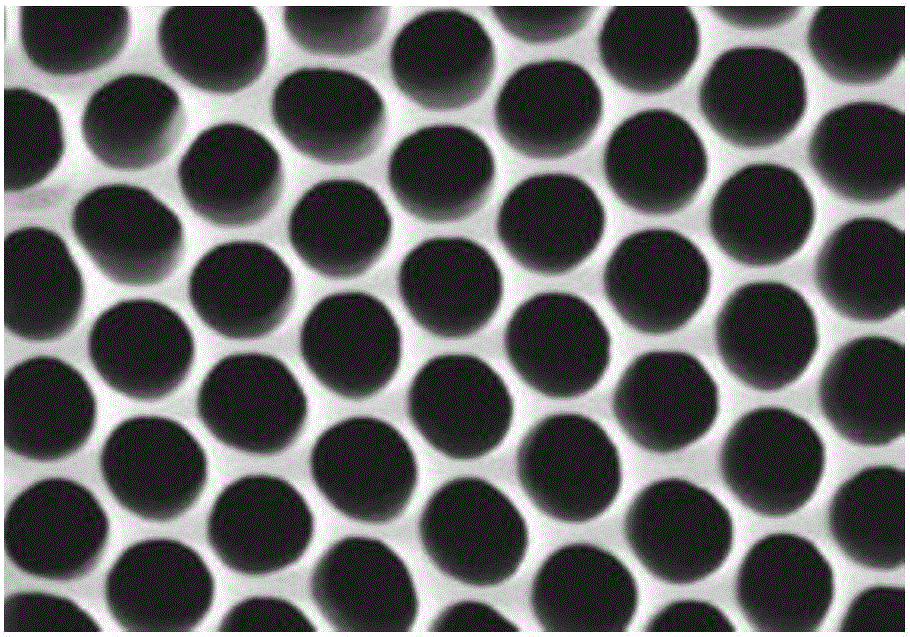

[0032] S2: Put the pre-prepared AAO template with a specified pore size distribution in a closed container, extract the air in the AAO template through a vacuum filter, and then inject the lithium iron phosphate precursor slurry into the AAO under negative pressure in the holes of the template and vacuum dried;

[0033] S3: Sintering the AAO template loaded with the lithium iron phosphate precursor under a certain atmosphere, and removing the AAO template with NaOH solution to prepare lithium iron phosphate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com