Laser polarization state control stabilizing device and control stabilizing method

A technology of stabilizing device and stabilizing method, applied in the field of laser, can solve problems such as complex device, and achieve the effect of short search time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

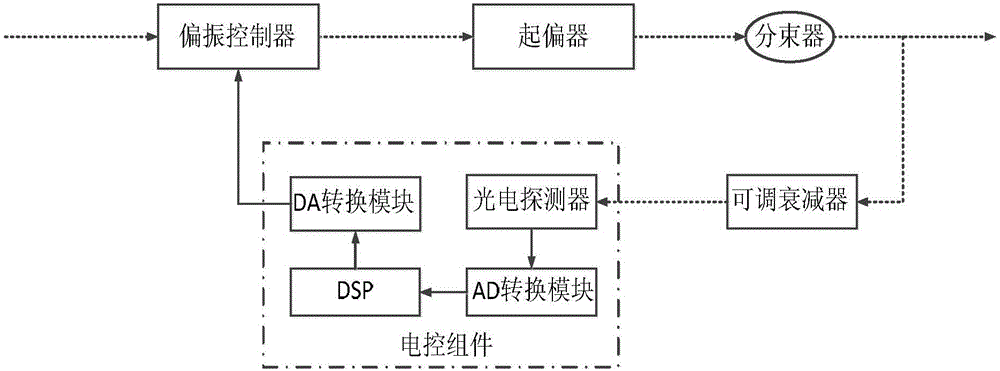

Method used

Image

Examples

Embodiment 1

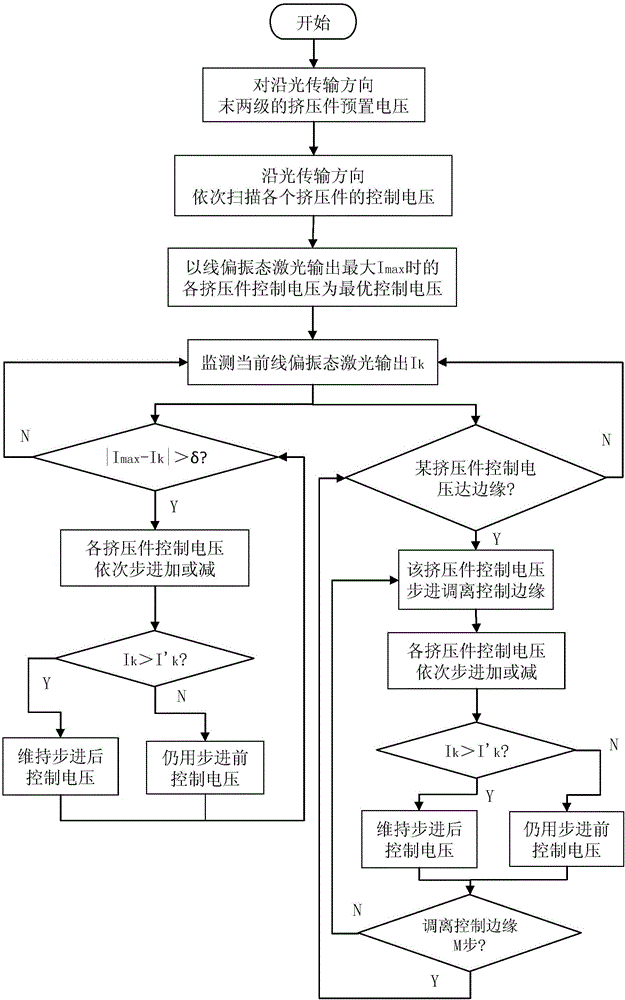

[0054] Embodiment 1 of the method for stabilizing the laser polarization state adopts the embodiment of the above-mentioned laser polarization state stabilization control device, and its flow chart is as follows figure 2 shown, including the following steps:

[0055] Step Ⅰ. Search for the optimal control voltage

[0056] Ⅰ-1. Preset voltage

[0057] In this example, the order of the four extrusions of the polarization controller is known, the electric control component presets the voltage -3V to the last two extrusions in the polarization controller along the light transmission direction, and the speed at which the last two extrusions are introduced The phase difference between the axes is 0.45π and 0.55π respectively;

[0058] Ⅰ-2. Control voltage scanning

[0059] In this example, along the direction of light transmission, the control voltage of each extrusion is scanned sequentially. When scanning the control voltage of a certain extrusion, the control voltages of othe...

Embodiment 2

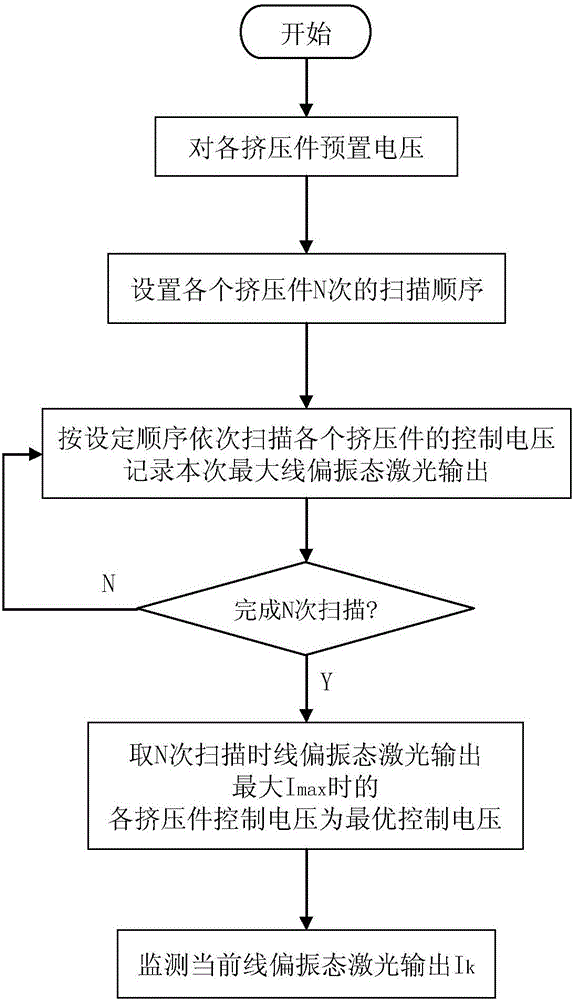

[0073] Embodiment 2 of the method for stabilizing the laser polarization state adopts the above-mentioned embodiment of the laser polarization state stabilization control device, and includes the following steps:

[0074] Step Ⅰ. Search for the optimal control voltage

[0075] The flow chart of this step is as follows image 3 shown.

[0076] Ⅰ-1. Preset voltage

[0077] In this example, the order of the four extrusions of the polarization controller is unknown, and the voltage of each extrusion of the polarization controller is preset at -3V, so that the phase difference between the fast and slow axes introduced by each extrusion is in the range of 0.5π±0.2π Inside.

[0078] Ⅰ-2. Control voltage scanning

[0079] The four extrusions of the polarization controller are respectively numbered 0, 1, 2, and 3, and the number of scans is N=4, and the scan order of the 4 scans is respectively: 0123, 0132, 0213, and 0231. According to the above sequence, the control voltage of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com