Austenitic stainless steel belt for control rod driving mechanism magnetism isolation piece and preparation method of austenitic stainless steel belt

A technology of austenitic stainless steel and driving mechanism, applied in the field of materials, can solve the problem of difficult to ensure the weak magnetic requirements of products, and achieve the effect of improving the qualified rate of magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

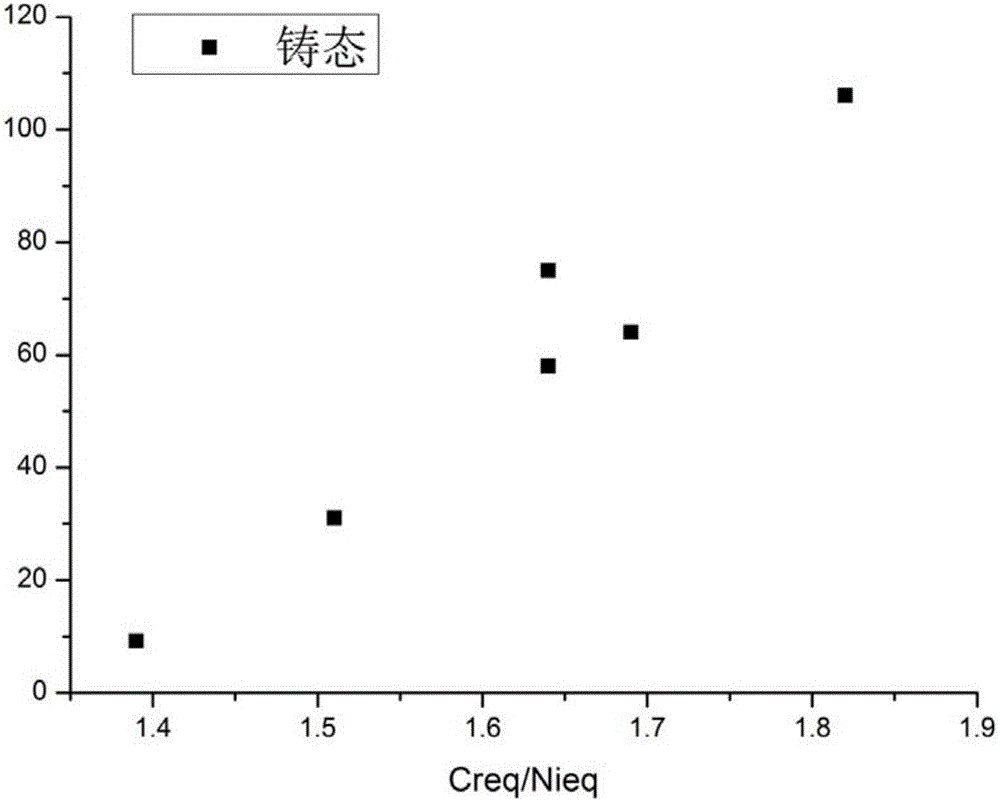

[0048] According to the preparation method of the austenitic stainless steel strip material for the magnetic isolation sheet of the control rod driving mechanism of the present invention, a series of austenitic stainless steels with different chemical compositions are smelted in a 25 kg vacuum induction furnace. The magnetic non-destructive tester for oxides in austenitic stainless steel tubes disclosed by ZL 03 1 09490.2 is used to detect the magnetism of alloy ingots, and the relationship between the magnetism of alloy ingots and the ratio Creq / Nieq of chromium equivalent to nickel equivalent in the alloy is obtained as follows: image 3 shown. After analyzing the chemical composition and checking the alloy melting and casting process, no abnormalities were found. Therefore, this magnetic non-destructive testing data is stored in the magnetic non-destructive testing signal database under the normal production process of austenitic stainless steel as the normal magnetic testi...

Embodiment 2

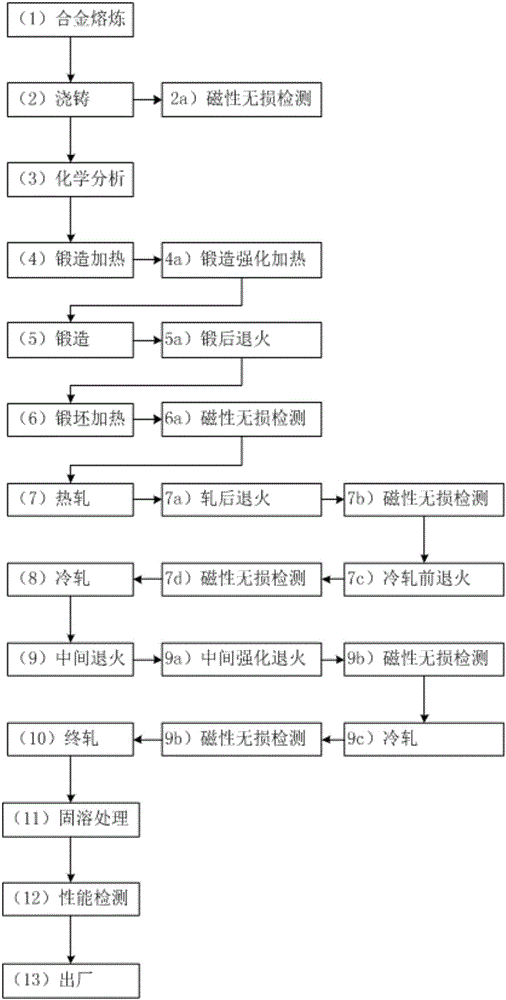

[0051] According to the preparation method of the austenitic stainless steel strip material for the magnetic isolation sheet of the control rod driving mechanism of the present invention, a 500kg vacuum induction furnace is used to smelt austenitic stainless steel whose chemical composition is 18.26%Cr-8.65%Ni-0.052%C-1.16%Mn-Fe Tensitic stainless steel. The non-destructive testing instrument for magnetic oxides in austenitic stainless steel tubes revealed by ZL 03 1 09490.2 is used to detect the magnetic properties of alloys in the production process of thin plates according to figure 2 As shown, the magnetic changes of the alloy are monitored to realize the whole process control, and the monitoring results of the alloy in each magnetic monitoring control are as follows:

[0052] The magnetic detection signal of the alloy ingot is 64±7, the detection signal of the forged billet is 23±2, the detection signal of the hot-rolled plate (not pickled or brightly polished) is 17±2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com