Method of measuring plane stress of anisotropic material

A technology of plane stress and anisotropy, applied in the direction of measuring force, measuring device, instrument, etc., can solve the problem of low measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

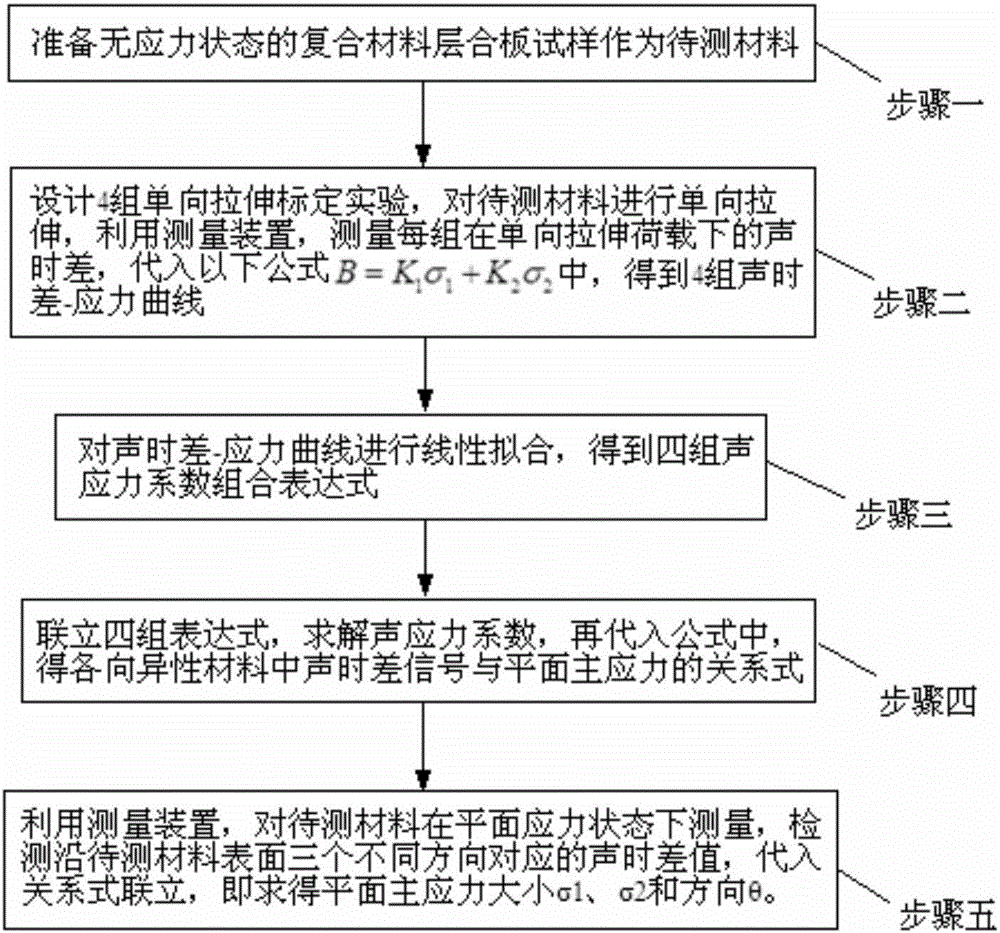

[0057] Embodiment 1: The method for measuring the plane stress of anisotropic materials in this embodiment includes the following steps:

[0058] 1. Prepare a composite laminate sample in an unstressed state as the material to be tested;

[0059] 2. Design 4 sets of unidirectional tensile calibration experiments, select 4 sets of calibration directions, and perform uniaxial stretching on the material to be tested. Use the device for measuring the plane stress of anisotropic materials to measure the sound of each group under unidirectional tensile load. The time difference is substituted into the following formula to obtain 4 sets of acoustic time difference-stress curves respectively;

[0060] B=K 1 σ 1 +K 2 σ 2 ,

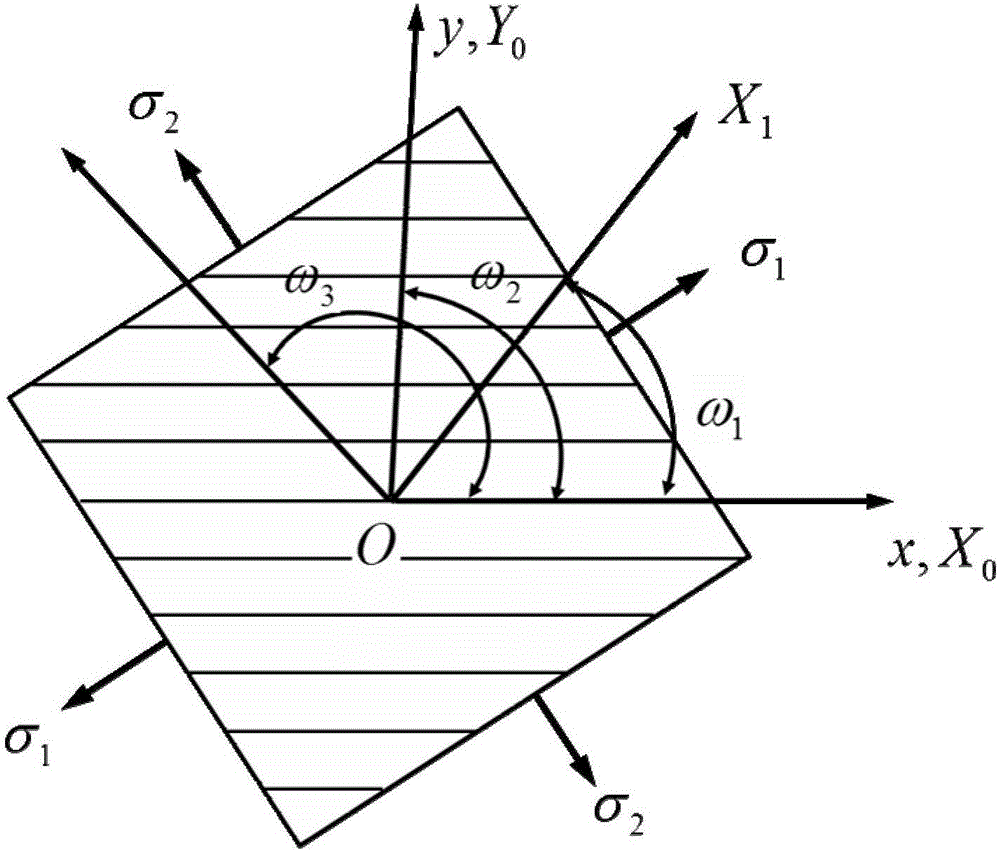

[0061] where K 1 =m 1 (cos2θ+cos2ω)+m 2 +m 3 cos2θcos2ω+m 4 sin2θsin2ω,

[0062] K 2 =-m 1 (cos2θ-cos2ω)+m 2 -m 3 cos2θcos2ω-m 4 sin2θsin2ω

[0063] B is the acoustic time difference of the detection signal, σ 1 is the first principal stress of th...

specific Embodiment approach 2

[0069] Specific implementation mode two: the difference between this implementation mode and specific implementation mode one is: combining Figure 5 To illustrate this embodiment, the device for measuring the plane stress of anisotropic materials includes an ultrasonic transducer group, an ultrasonic oblique incidence wedge 2, a signal generator 3, a digital oscilloscope 4, and an analysis and processing software 5;

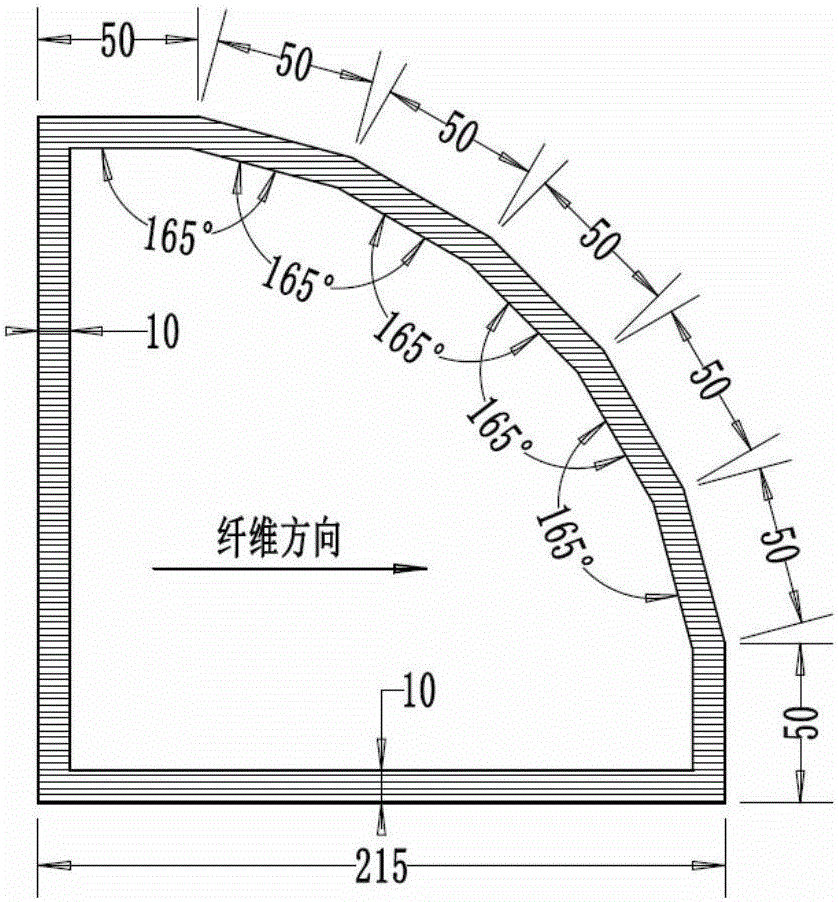

[0070] The shape of the ultrasonic oblique incidence wedge 2 is a regular octagon, and the oblique incidence angle is 34°;

[0071] The ultrasonic transducer group includes a first ultrasonic longitudinal wave excitation probe 11, a second ultrasonic longitudinal wave excitation probe 12, a third ultrasonic longitudinal wave excitation probe 13, a first ultrasonic longitudinal wave receiving probe 14, a second ultrasonic longitudinal wave receiving probe 15 and a third ultrasonic longitudinal wave receiving probe 15. Ultrasonic longitudinal wave receiving probe ...

specific Embodiment approach 3

[0076] Embodiment 3: This embodiment is different from Embodiment 2 in that: the ultrasonic oblique incidence wedge 2 is made of polytetrafluoroethylene. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com