Optical-mechanical-electric integrated mechanical part size detecting device

A mechanical parts, opto-mechanical and electrical technology, applied in the field of automatic detection devices, can solve problems such as low efficiency, affecting device life, stability and reliability, and slow detection speed, so as to achieve safe and reliable use, stable and reliable detection data, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

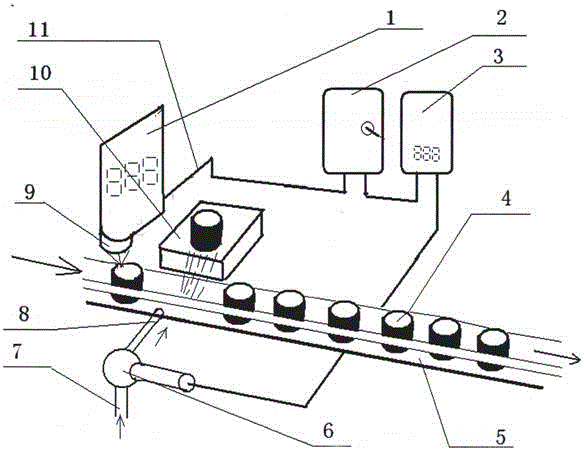

[0015] Such as figure 1 As shown, the present invention is mainly designed for detecting a batch of disk sleeve parts of the same size, and consists of three parts: a photoelectric control system, a product assembly line and a rejecting system for unqualified products. The product assembly line passes through the photoelectric control system, and the detected products 4 is conveyed on the automatic transmission belt 5, the photoelectric control system is connected by the composite light source scanner 1 and the photoelectric controller 2 through the data control line 11, and the electronic timer 3 is connected with the photoelectric controller 2, unqualified products The rejection system is provided with a non-conforming product container 10 on one side of the electromagnetic coil air valve 6, and the non-conforming product rejection system is placed on both sides of the detected product 4, which can just detect the products on the automatic conveyor belt 5. Photoelectric cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal pressure | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com