Mixing plant waste residue processing technique and equipment

A treatment process and mixing station technology, applied in the field of mixing stations, can solve problems such as increasing production costs, increasing the amount of admixtures, and uncontrollable separation of slurry water concentration, achieving broad market prospects and reducing environmental risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

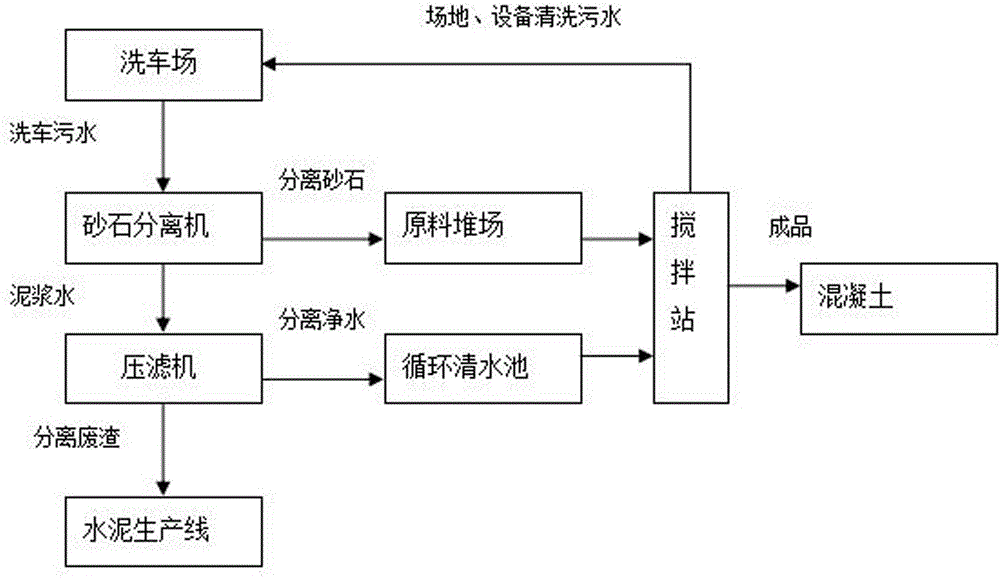

[0015] See figure 1 , A waste slag treatment process of a mixing station, including the following process steps: the mixing conveyor is driven to the car platform of the car wash to clean the residual material in the tank; the cleaned waste concrete is poured into the chute of the feeding device, and the The auger pushes the waste concrete into the sand and gravel separator for cleaning and separation; the separated sand is pushed to a height by the sand lifter and discharged through the sand outlet, and the separated stones are directly discharged through the stone outlet. Return to the mixing station for reuse; the sewage is discharged into the diversion trough outside the sand and gravel separator through the drain (overflow) on the frame of the gravel separator, and flows into the slurry tank, and the sewage in the slurry tank is removed by the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com