Synthesis method of ZSM-5 molecular sieve and ZSM-5 molecular sieve

A technology of ZSM-5 and synthesis method, which is applied in the direction of nanotechnology, crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., which can solve the problem of difficulty in fully utilizing acidic sites, small pore size, and easy accumulation of catalysts. Carbon deactivation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

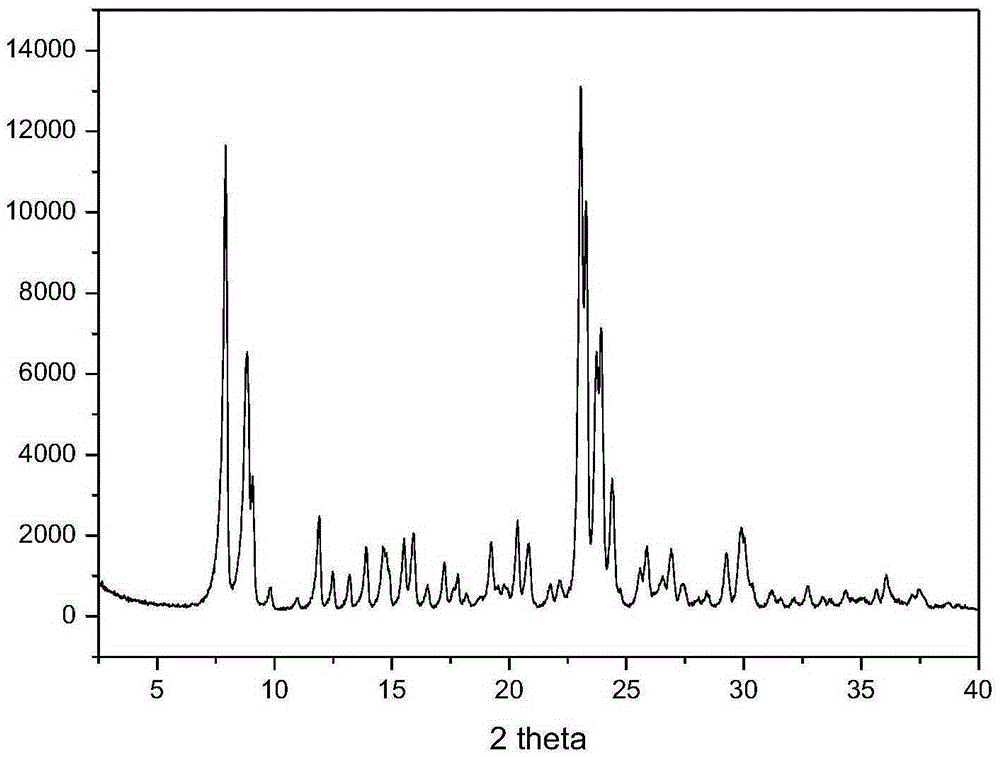

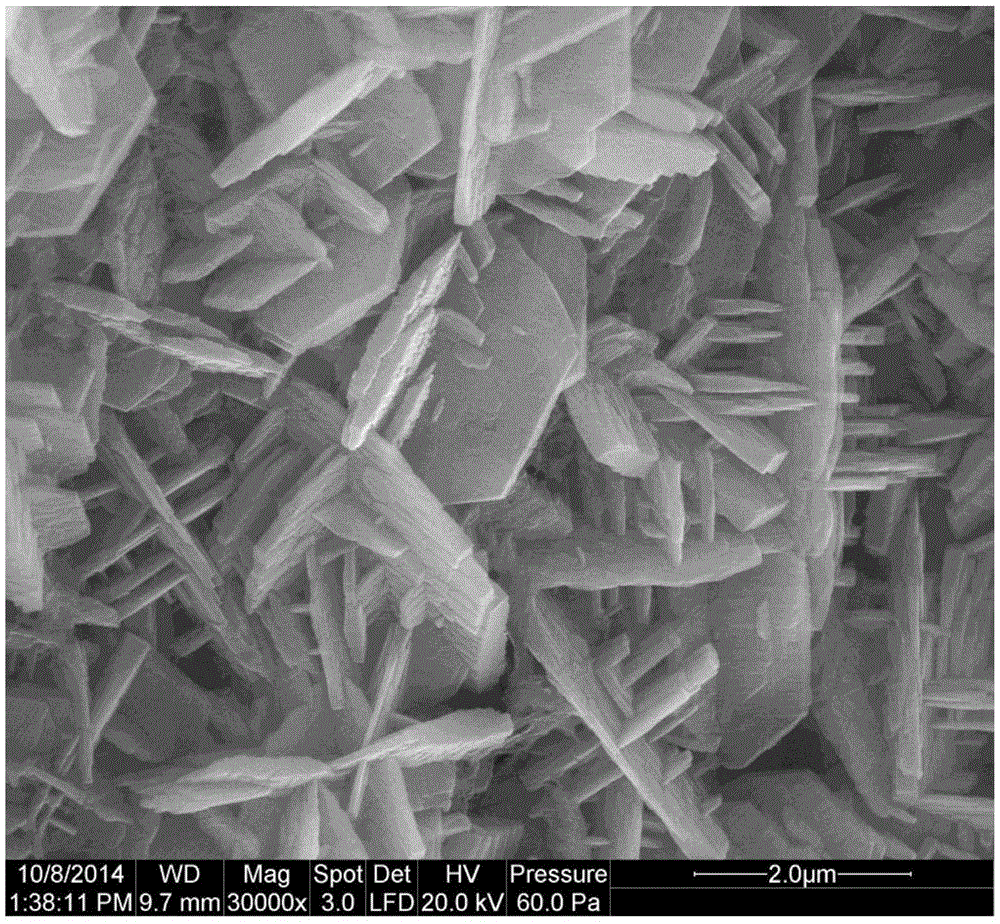

[0012] Embodiment 1: NaOH 0.3g, NaAlO 2 Put 0.437g in a 250ml polypropylene beaker, add 30g of deionized water, stir at room temperature for 5 minutes to make NaOH and NaAlO 2 Dissolve, add 10g of piperidine to the above solution, stir for 10 minutes to obtain a uniform solution, slowly add 20g of LUDOX AS-40 silica sol into the above solution dropwise under stirring. The resulting mixture was placed under magnetic stirring at 30°C (600 rpm) for 4h for gelation / precrystallization, and then transferred to a 100ml autoclave with a Teflon liner for dynamic crystallization at 145°C for 5 days (taken The mode of operation is to place the reaction kettle on a rotating motor, and the motor speed is 60 rpm). After the crystallization, the reaction kettle was placed in cold water to quickly cool down to room temperature, then suction filtered and washed repeatedly with 1L of deionized water, and the obtained precipitate was dried at 110°C for 12 hours. Then roast in the muffle furnac...

Embodiment 2

[0013] Embodiment 2: operation is the same as embodiment 1, the add-on of piperidine is 5.677g. XRD showed that the obtained sample was ZSM-5 molecular sieve.

Embodiment 3

[0014] Embodiment 3: NaOH 0.32g, NaAlO 2 Put 0.656g in a 250ml polypropylene beaker, add 36g of deionized water, stir at room temperature for 5 minutes to make NaOH and NaAlO 2 Dissolve, add 8.52g of piperazine to the above solution, stir for 10 minutes to obtain a uniform solution, slowly add 20g of LUDOX AS-40 silica sol into the above solution dropwise under stirring. The resulting mixture was placed under magnetic stirring at 25°C (600 rpm) for 3h for gelation / precrystallization, and then transferred to a 100ml autoclave with a Teflon liner for dynamic crystallization at 150°C for 5 days (taken The mode of operation is to place the reaction kettle on a rotating motor, and the motor speed is 40 rpm). After the crystallization, the reaction kettle was placed in cold water to quickly cool down to room temperature, then suction filtered and washed repeatedly with 1L of deionized water, and the obtained precipitate was dried at 110°C for 12 hours. Then roast in the muffle fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com