Leather and production method thereof

A production method and leather technology, applied in textiles and papermaking, etc., can solve the problem that the leather surface is not scratch-resistant, and achieve the effect that it is not easy to whiten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

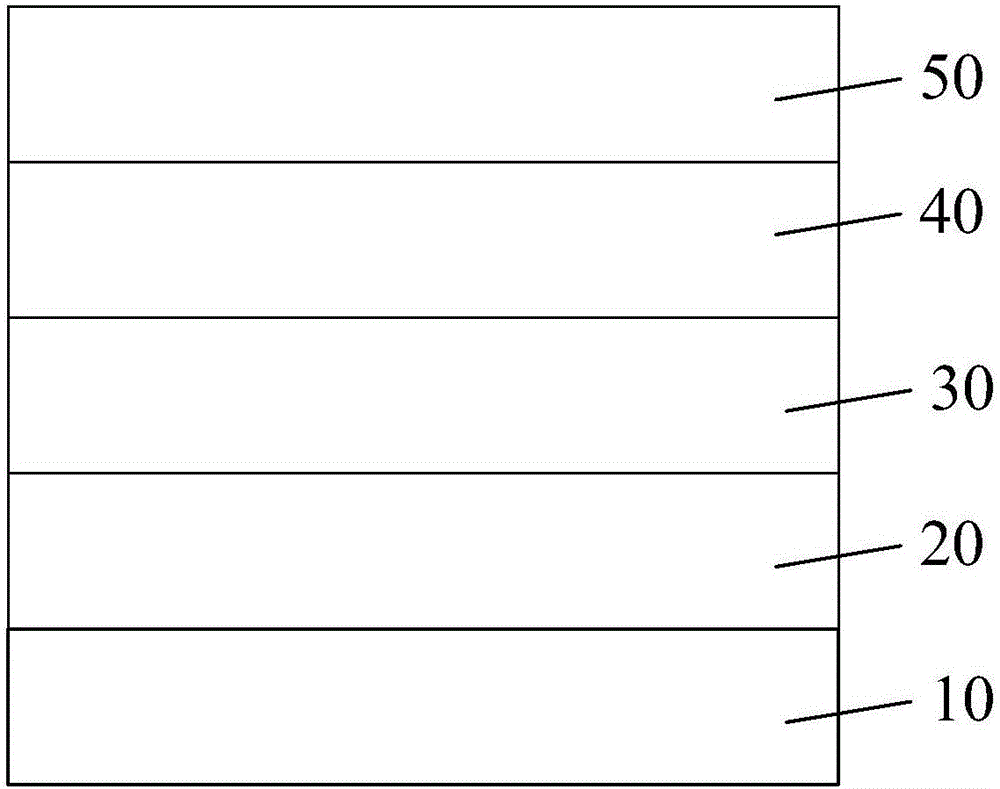

Image

Examples

Embodiment 1

[0039] In parts by weight, the composition forming the bottom layer includes 100 parts of PVC resin powder, 50 parts of DOP plasticizer, 20 parts of ESPO plasticizer, 1.0 part of AC foaming powder, 100 parts of ground calcium carbonate, 2.0 parts of barium zinc heat stabilizer and 1.0 parts of lubricant.

[0040] In parts by weight, the composition forming the surface layer includes 100 parts of PVC resin powder, 60 parts of DOP plasticizer, 6 parts of ESPO plasticizer, 2.0 parts of barium zinc heat stabilizer and 20 parts of light carbonic acid calcium.

[0041] The bottom layer and the surface layer with a thickness of 0.22 mm are sequentially arranged on the base fabric by calendering technology, and the structural film layer with the bottom layer and the surface layer is sent to a foaming furnace for foaming to form a foam layer with a thickness of 0.25 mm. And the expansion ratio is 1.3 (thickness of the foam layer=thickness of the bottom layer×expansion ratio). Surface t...

Embodiment 2

[0044] The difference from Example 1 is that in the process of forming the surface layer, the running speed of the control roller is 18m / min.

Embodiment 3

[0046] The difference from Embodiment 1 is that: before setting the bottom layer, a glue layer is set on the surface of the base cloth, and the glue layer is arranged between the base cloth and the bottom layer. During the formation of the top layer, the rotational speed of the control roll was 12.5 m / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com