Dyeing and finishing process for N-400 high-stretch nylon fabric

A process, dyeing and finishing technology, which is applied in the field of dyeing and finishing of N-400 high-elastic nylon fabric, can solve the problems of increased cost, high damage, non-sagging, etc., achieves reduced floor space, low mechanical height, and promotes recycling. Shrink effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

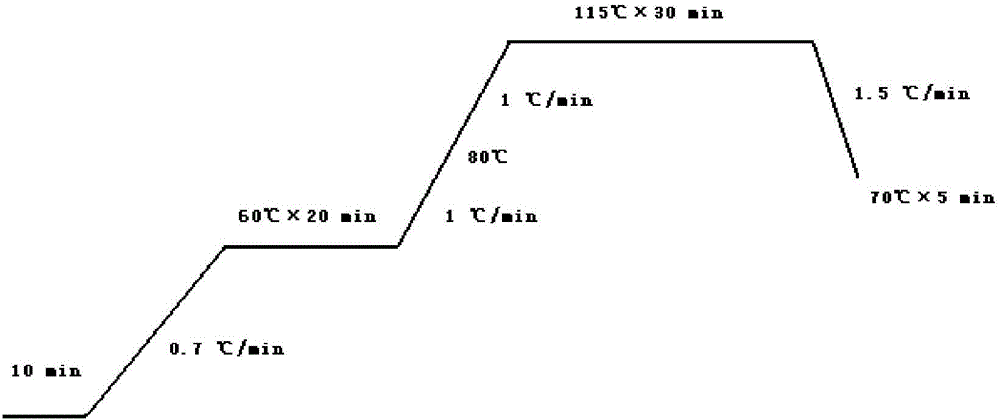

Examples

example 1

[0027] white embryo

[0028] Warp direction: Nylon 66 high elastic yarn 40 / 34

[0029] Weft direction: Nylon 66 high elastic yarn 40 / 34*2

[0030] Title: 16524

[0031] Weft density: 38 shuttles / 76 threads

[0032] Gray cloth door width: 206.6cm

[0033] Weave: Twill

[0034]Dyeing and finishing process: fabric joining→desizing→dyeing→dehydration→opening→drying→setting

[0035] Cloth receiving: left and right (record the number of meters and check the situation of incoming cloth)

[0036] Desizing:

[0037] Chemical formula: liquid caustic soda 63.75KG

[0038] Refining agent 7.65KG

[0039] Deoiling spirit 5.1KG

[0040] Special effect spandex degreasing spirit 5.1KG

[0041] Refined Penetrant 2.55KG

[0042] Chelating dispersant 1.91KG

[0043] Water 2550L

[0044] Temperature: 100°C

[0045] Speed: 35m / min

[0046] at the mercy of

[0047] dyeing:

[0048] Orange dye formula: Yellow NHF-S-1 concentration (%) 1.7

[0049] Acid Red GN concentration (%)0.2

...

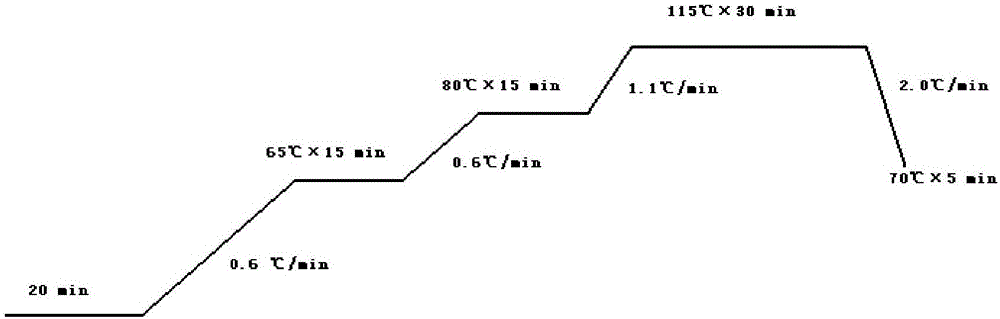

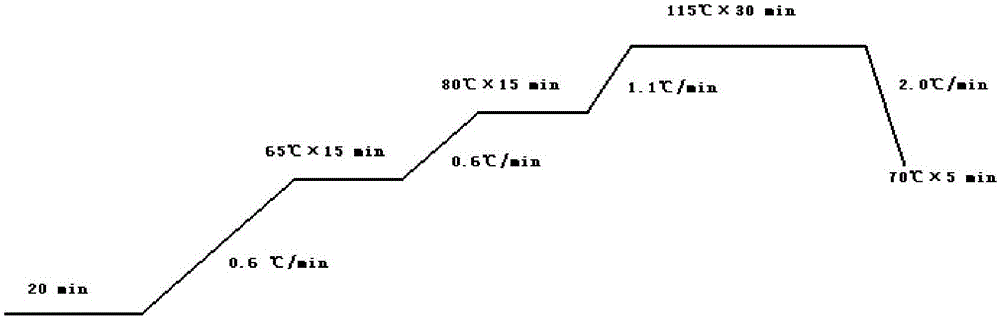

example 2

[0080] white embryo

[0081] Warp direction: Nylon 66 high elastic yarn 40 / 34

[0082] Weft direction: Nylon 66 high elastic yarn 40 / 34*2

[0083] Title: 16524

[0084] Weft density: 45 shuttles / 90 threads

[0085] Gray cloth door width: 206.6cm

[0086] Organization: jacquard

[0087] Dyeing and finishing process: fabric joining→desizing→dyeing→dehydration→opening→drying→setting

[0088] 1. Cloth receiving: left and right (record the number of meters and check the incoming cloth)

[0089] 2. Desizing:

[0090] Chemical formula: liquid caustic soda 63.75KG

[0091] Refining agent 7.65KG

[0092] Deoiling spirit 5.1KG

[0093] Special effect spandex degreasing spirit 5.1KG

[0094] Refined Penetrant 2.55KG

[0095] Chelating dispersant 1.91KG

[0096] Water 2550L

[0097] Temperature: 100°C

[0098] Speed: 35m / min

[0099] at the mercy of

[0100] dyeing:

[0101] Peacock blue dye formula: Yellow 4GL concentration (%) 0.2

[0102] Tellon Turquoise Blue M-5G 85...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com