FRP rib concrete pipe sheet with embedded steel bars

A technology of concrete and concrete layer, which is applied in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of brittle failure, large deformation, low elastic modulus, etc., and achieve the effect of good ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

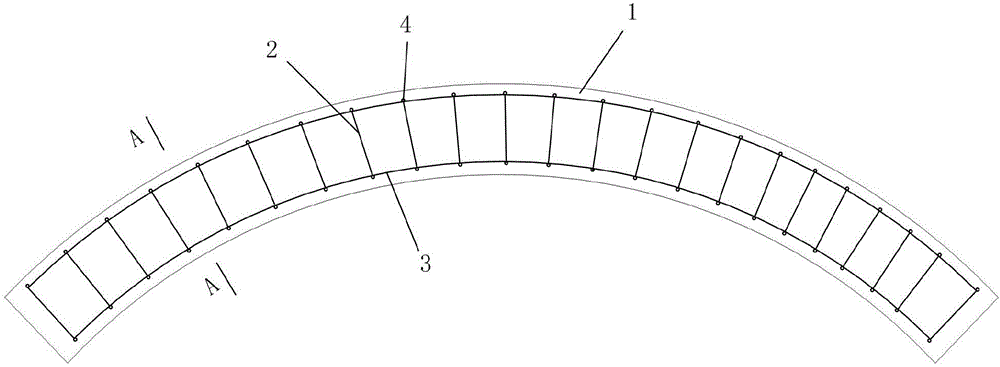

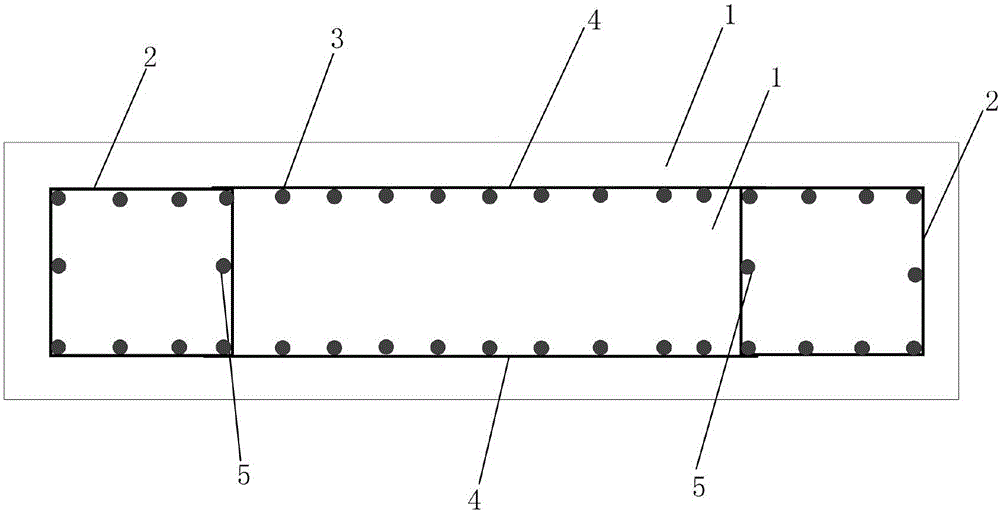

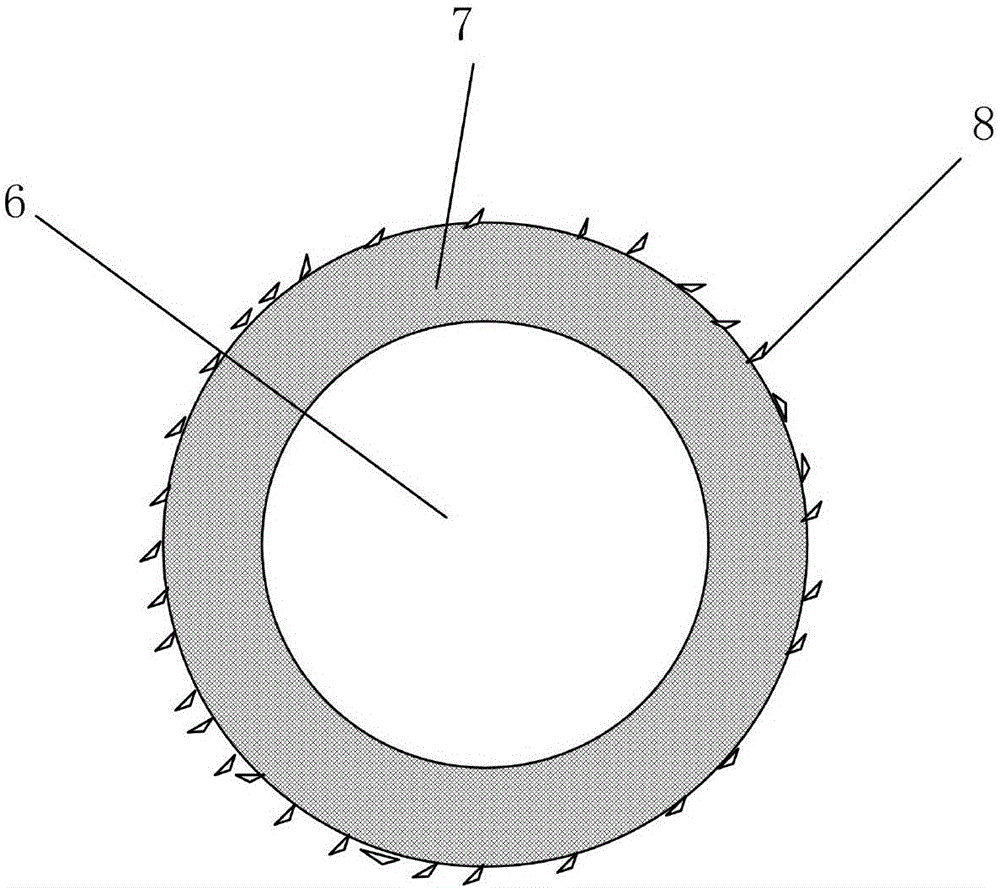

[0017] Such as figure 1 and figure 2 As shown, this example provides an FRP tendon segment with embedded steel bars, the structure is composed of FRP mesh with embedded steel bars and a cast-in-place concrete layer 1, and the FRP mesh is set in the cast-in-place concrete layer 1. The FRP reinforcement mesh with embedded reinforcement is composed of FRP stressed reinforcement 3 with embedded reinforcement, FRP distribution reinforcement 4 with embedded reinforcement, FRP waist reinforcement 5 with embedded reinforcement and FRP stirrup 2. Members 2, 3, 4 and 5 are connected together by binding. Such as image 3 As shown, the FRP bars embedded with steel bars are composed of steel bars 6 , FRP layers 7 and sticky sand 8 .

[0018] Feed steel bars 6 soaked in epoxy resin and fiber bundles together into a pultrusion die acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com