Pickling process of fermented ham

A technology and technology of ham, which is applied in the field of pickling technology of fermented ham, can solve the problems of short storage period, poor quality, high salt content, etc., and achieve the effects of long storage period, controlled oxidation degree and low salt content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

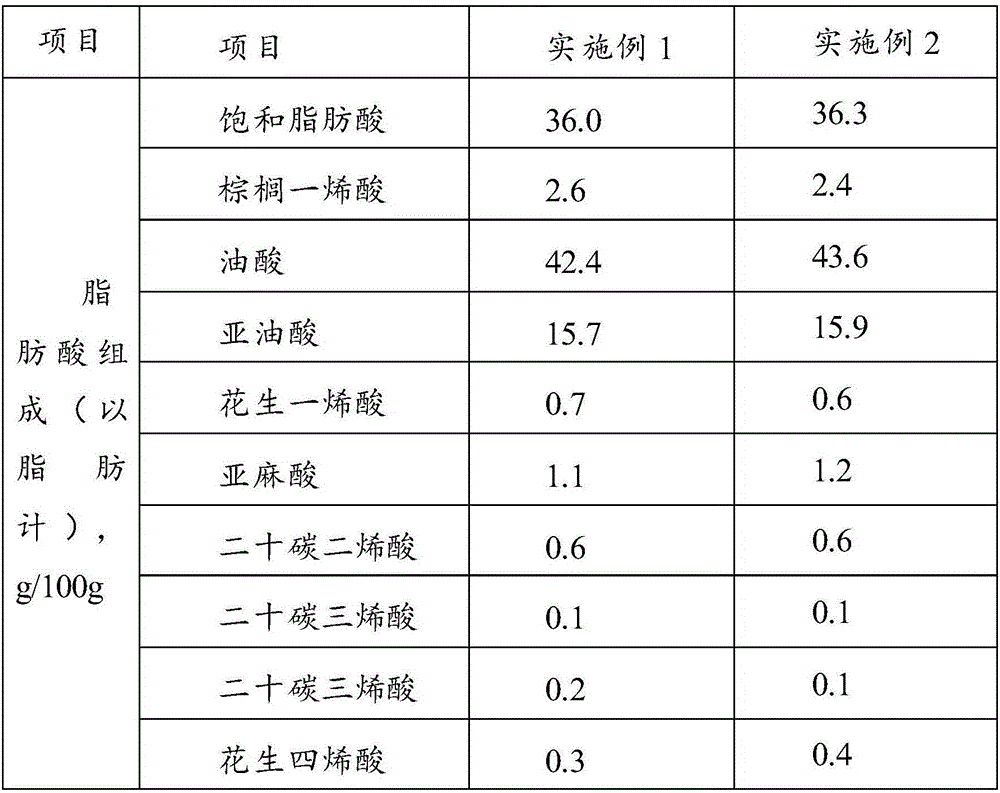

Embodiment 1

[0091] Select 400 hind legs of Sanmenxia young eagle black pigs with a specification range of 12-13 kg. The raw material trimming requirements are: the skin on the back of the legs is peeled off to the elbow to form a triangle, and the meat surface of the legs (except the center of the legs) is covered with a layer of fat Floor. The slaughtering and dividing production workshop is transferred to the raw material entrance of the ham production workshop. The raw material legs are placed in the pre-cooling room with a room temperature of 4°C and pre-cooling for 12 hours.

[0092] The 1# pressure roller of the rolling machine is set to 0.2MPa, the pressure of the 2#, 3#, and 4# pressure rollers is set to 0.4MPa, and the raw material legs pass through the rolling one by one. Rub the wet salt on the surface of the pigskin with your hands, and it must be rubbed evenly. The ratio of wet salt: add 1.5kg of water for every 50kg of salt. Sprinkle a layer of dry salt on the front meat su...

Embodiment 2

[0106] Select 200 hind legs of Sanmenxia young eagle black pigs with a specification range of 12-13 kg. The raw material trimming requirements are: the skin on the back of the legs is peeled off to the elbow to form a triangle, and the meat surface of the legs (except the center of the legs) is covered with a layer of fat Floor. The slaughtering and dividing production workshop is transferred to the raw material entrance of the ham production workshop. The raw material legs are placed in the pre-cooling room with a room temperature of 4°C and pre-cooling for 12 hours.

[0107] The 1# pressure roller of the rolling machine is set to 0.2MPa, the pressure of the 2#, 3#, and 4# pressure rollers is set to 0.4MPa, and the raw material legs pass through the rolling one by one. Rub the wet salt on the surface of the pigskin with your hands, and it must be rubbed evenly. The ratio of wet salt: add 1.5kg of water for every 50kg of salt. Sprinkle a layer of dry salt on the front meat su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com