Novel mattress support layer

A support layer and mattress technology, applied in mattresses, spring mattresses, stuffed cushions, etc., can solve the problems of unremovable and washable, unmanageable, insufficient support, etc., to achieve convenient transportation, fast production, and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

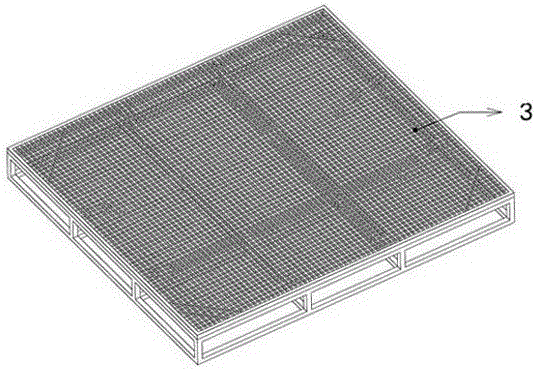

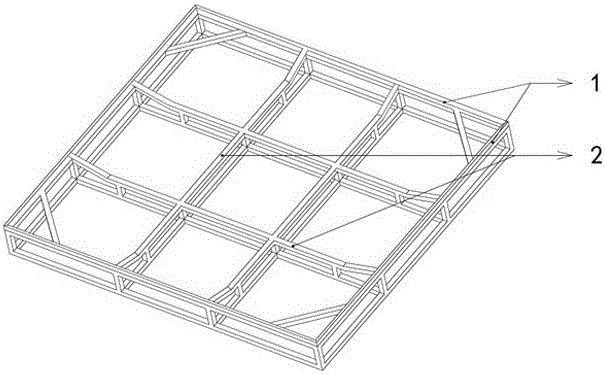

[0050] 1. Cut and blank all the profiles required for the production of supporting frame 1 and support frame 2, and form them by welding to form a 1×0.5m crib frame. Because the bed surface is small, the internal support frame can be used easily The cross-shaped structure ensures that the required support and durability can be achieved; then the surface of the frame is treated with moisture-proof, anti-oxidation, etc. to ensure aesthetics and durability; use nylon wires with a diameter of 0.5 mm, and combine 8 wires to form a cylinder Form a large strand, each strand has a pulling force of 45 lbs, use a warp and weft thread every 2 cm, and weave the bed surface with the warp and weft weaving meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com