Low-temperature plasma waste gas treatment apparatus

An exhaust gas treatment device and low-temperature plasma technology, which is applied in the direction of gas treatment, separation methods, and dispersed particle separation, etc., can solve the problems of unsatisfactory exhaust gas purification effect, and achieve the effect of fast response, good purification effect and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a low-temperature plasma waste gas treatment device, which not only has a simple structure, low manufacturing cost, good waste gas treatment effect, but also is very convenient to operate and maintain.

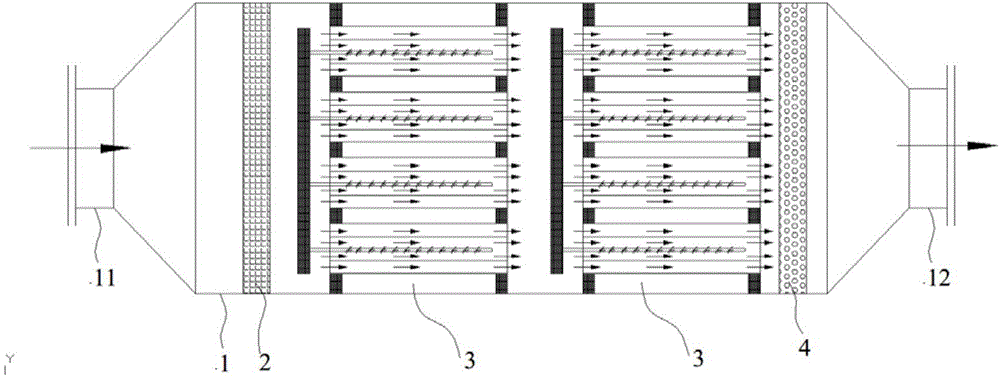

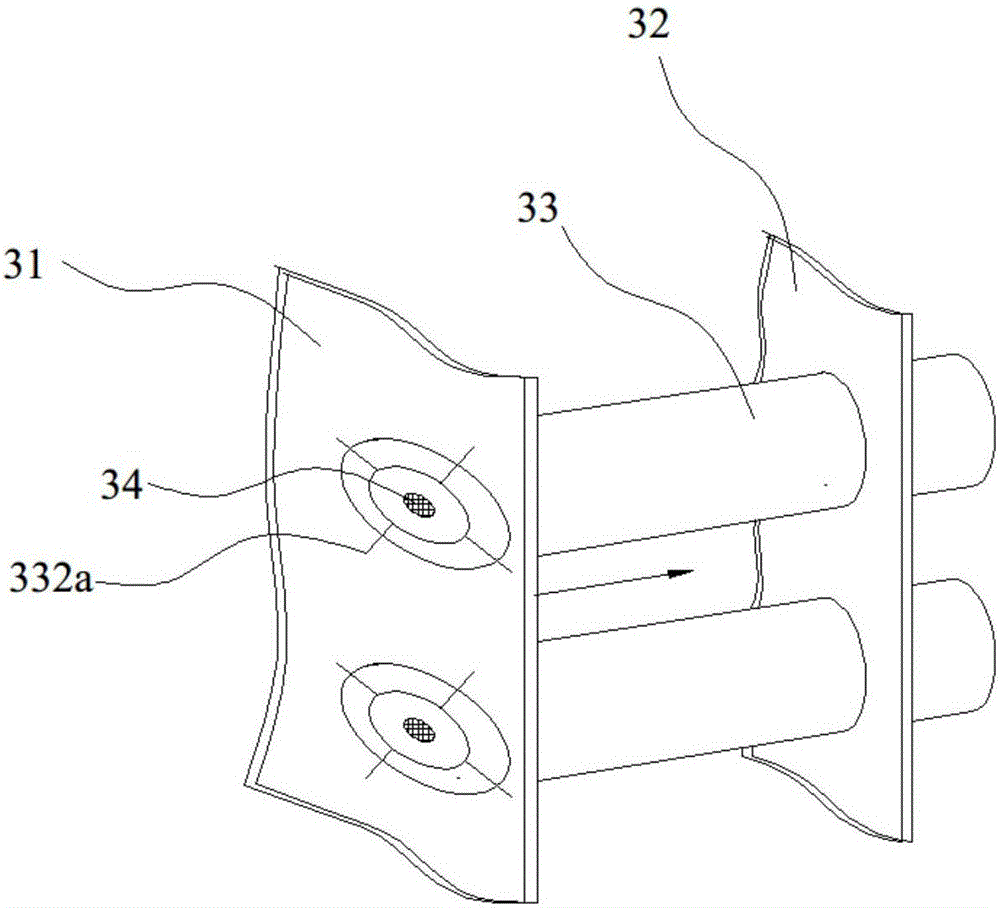

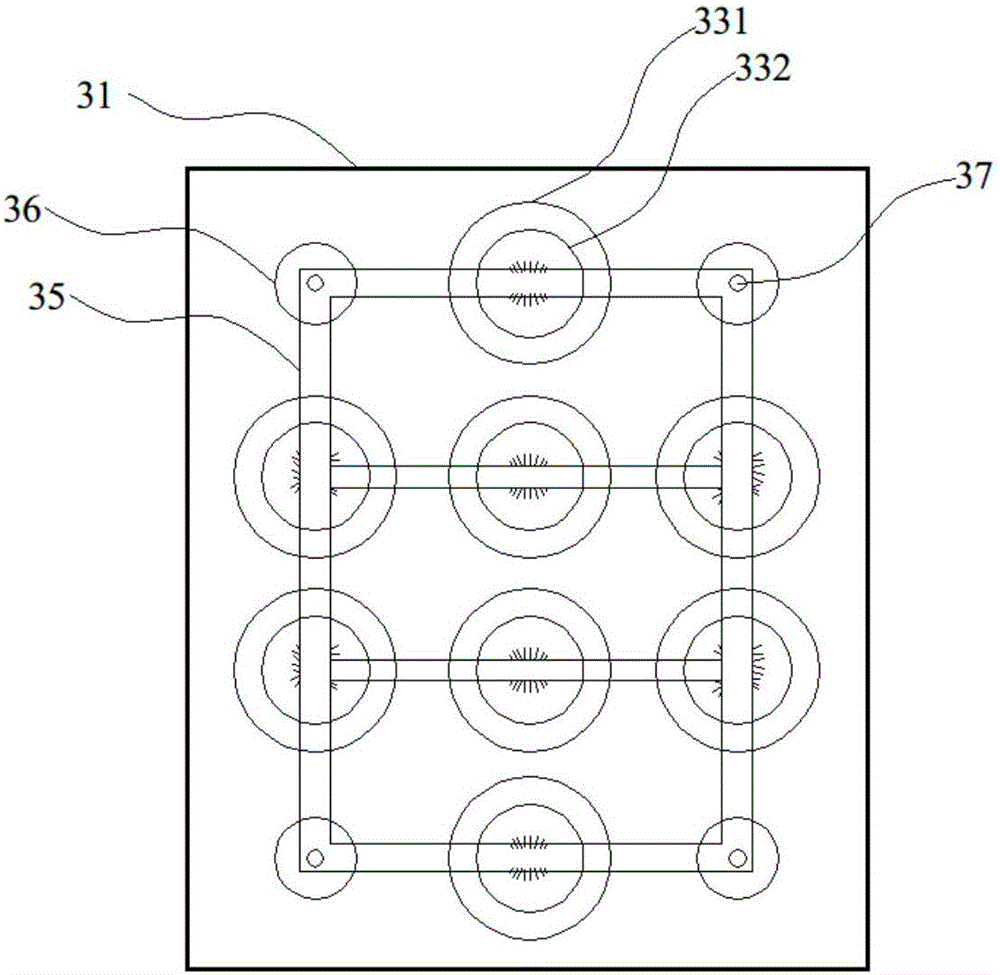

[0041] please participate Figure 1 to Figure 4 ,in figure 1 It is a schematic structural diagram of a low-temperature plasma waste gas treatment device in this embodiment; figure 2 Shown is a partial perspective view of the low temperature plasma reaction module in this embodiment; image 3 Shown is the left side view of the low temperature plasma reaction module in the present embodiment; Figure 4 It is a structural schematic diagram of the low-temperature plasma reaction tube in this embodiment.

[0042] Depend on figure 1 It can be seen that the low-temperature plasma exhaust gas treatment device of this embodiment includes a housing 1, and according to the flow direction of the gas, the rear end of the housing 1 is provided with an ai...

Embodiment 2

[0064] A low-temperature plasma exhaust gas treatment device in this embodiment includes a housing 1 and an air inlet 11 and an air outlet 12 respectively arranged at both ends of the housing 1 . The filter module 2, the photocatalytic oxidation module 3 and the activated carbon fiber filter module 4, wherein, the low temperature plasma reaction module 3 includes a first fixed plate 31, a second fixed plate 32 and an interval between the first fixed plate 31 and the n low-temperature plasma reaction tubes 33 between the second fixing plates 32 , the n low-temperature plasma reaction tubes 33 pass through the first fixing plate 31 and the second fixing plate 32 and extend along the flow path of the fluid.

[0065] The n low-temperature plasma reaction tubes 33 all include a cathode outer tube 331, an insulating medium inner tube 332 and an anode rod 34, and the anode rod 34 is arranged in the insulating medium inner tube 332, and the cathode outer tube 331 and the insulating med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com