Preparation method of NOx adsorbent

A nitrogen oxide and adsorbent technology, which is applied in the field of NO adsorbent preparation to achieve the effects of high NO adsorption activity, excellent NO adsorption performance and high adsorption activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

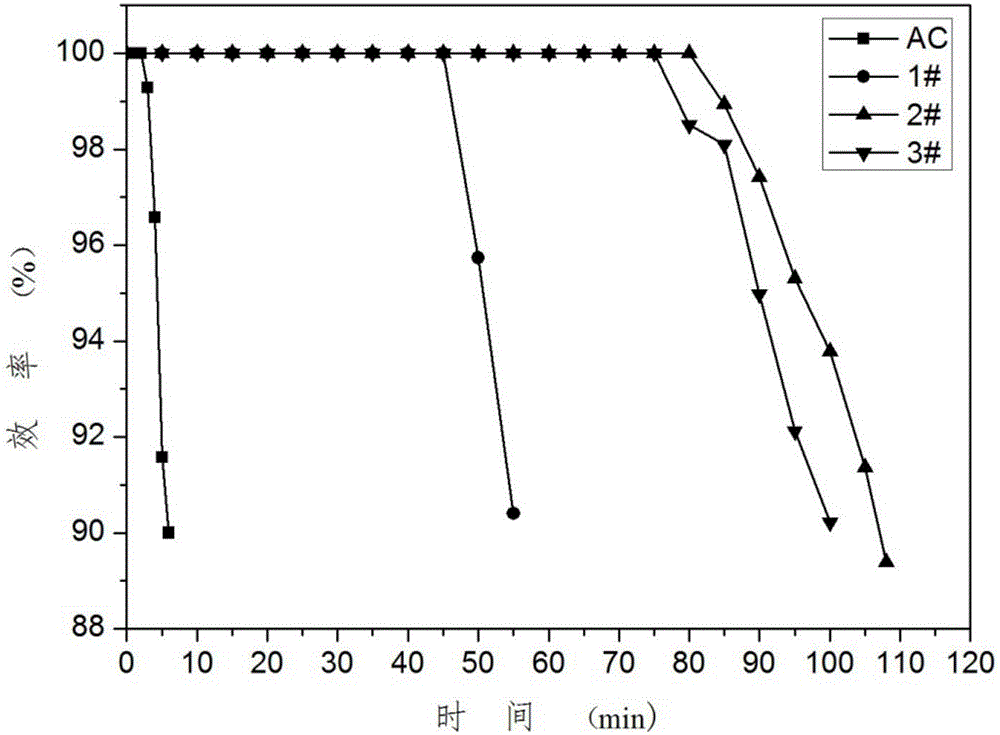

Embodiment 1

[0025] Put 18g of coconut shell activated carbon sieved to 16-20 mesh into 30ml of 0.5mol / L HNO 3 Immerse in a medium volume of the solution, and wash it repeatedly with deionized water after 12 hours until the filtrate is neutral (pH=7); then immerse in a medium volume of 30ml of 0.3mol / L cobalt nitrate solution for 12h; put it in an oven and dry at 105°C Dry for 12 hours; then immerse in 30ml of 0.1mol / L potassium nitrate solution with an equal volume for 12 hours; put it in an oven and dry it at 105°C for 12 hours; put the obtained solid into a tubular fiber resistance furnace, and bake it at 400°C under nitrogen protection After 2 hours, it was naturally cooled to room temperature to obtain 1# adsorbent.

Embodiment 2

[0027] Put 18g of coconut shell activated carbon sieved to 16-20 mesh into 30ml of 0.5mol / L HNO 3 Immerse in a medium volume of the solution, and wash it repeatedly with deionized water after 12 hours until the filtrate is neutral (pH=7); then immerse in a medium volume of 30ml of 0.3mol / L cobalt nitrate solution for 12h; put it in an oven and dry at 105°C Dry for 12 hours; then immerse in 30ml of 0.5mol / L potassium nitrate solution with an equal volume for 12 hours; put it in an oven and dry at 105°C for 12 hours; put the obtained solid into a tubular fiber resistance furnace, and bake it at 400°C under nitrogen protection After 2 hours, it was naturally cooled to room temperature to obtain 2# adsorbent.

Embodiment 3

[0029] Put 18g of coconut shell activated carbon sieved to 16-20 mesh into 30ml of 0.5mol / L HNO 3 Immerse in a medium volume of the solution, and wash it repeatedly with deionized water after 12 hours until the filtrate is neutral (pH=7); then immerse in a medium volume of 30ml of 0.3mol / L cobalt nitrate solution for 12h; put it in an oven and dry at 105°C Dry for 12 hours; then immerse in 30ml of 0.6mol / L potassium nitrate solution with an equal volume for 12 hours; put it in an oven and dry at 105°C for 12 hours; put the solid into a tubular fiber resistance furnace, and bake it at 400°C under nitrogen protection After 2 hours, it was naturally cooled to room temperature to obtain 3# adsorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com