Additive manufacturing model processing system

A model processing and additive manufacturing technology, applied in the field of additive manufacturing model processing systems, can solve the problems of secondary development of additive manufacturing systems, difficulty in exchanging data, and high price, so as to reduce follow-up meaningless labor and improve The effect of improving reliability and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

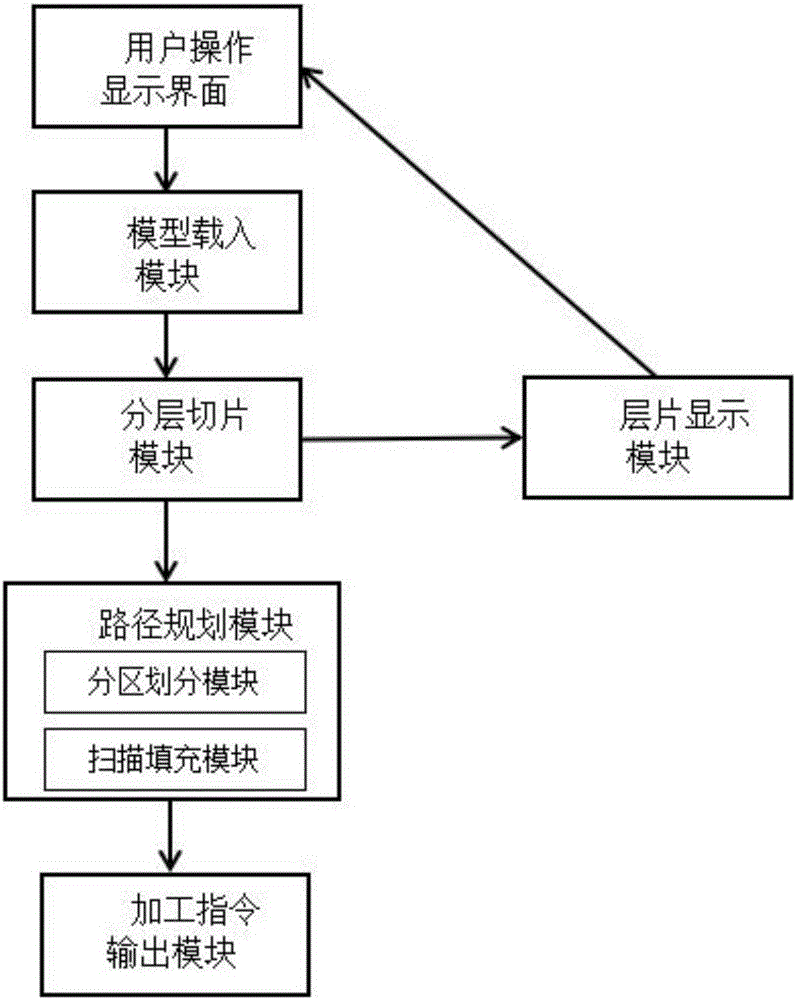

[0019] A model processing system for additive manufacturing, comprising: a user operation display interface 1, a model loading module 2, a layer slicing module 3, a layer display module 4, a path planning module 5 and a processing instruction output module 6.

[0020] The user operation display interface 1 includes an input module and a ply display interface, wherein the input module is used for inputting setting and modifying parameter values, and the ply display interface is used for displaying the ply profile data transmitted from the ply display module 4 . The model loading module 2 is used to read the geometric information data of the loaded model, and perform topology calculation on the read model data according to the parameter values read from the input module, and the hierarchical slicing module 3 according to the parameters read from the input module Slice the model loaded by the model loading module to obtain the slice contour data, and optimize the slice contour d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com