Machining method for cylinder bores of aluminum alloy cylinder block with simulating cylinder cover

A processing method and technology of aluminum alloy, applied in the field of engine cylinder block, can solve the problems of the overall structural limitation of the engine cylinder block, poor heat dissipation of cast iron, and inconsistent cylinder hole deformation, so as to reduce microscopic deformation, reduce weight, and improve uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

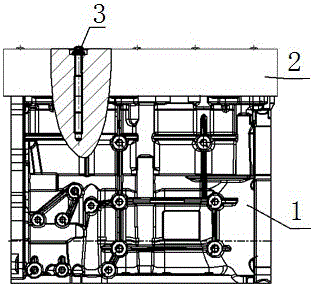

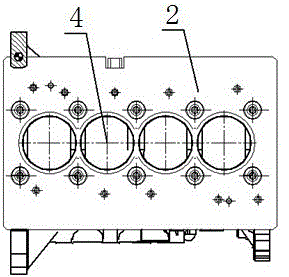

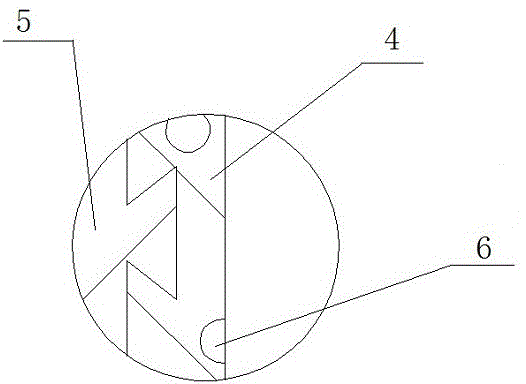

[0022] see Figure 1 to Figure 3 , the invention provides a cylinder hole processing method of an aluminum alloy cylinder block with a simulated cylinder head, which comprises the following steps:

[0023] 1) Preliminary machining of the cylinder bore, rough boring of the cylinder bore 4, and then fixing the simulated cylinder head 2 to the cylinder head installation position of the cylinder block 1 through the bolt 3, and then semi-finishing and fine boring of the cylinder bore 4 , and then loosen the bolt 3, and unload the simulated cylinder head 2;

[0024] 2) Cylinder bore coating pretreatment, using mechanical processing to process regular grooves on the bore wall of the cylinder bore 4 to enhance the firmness of the coating material on the bore wall of the cylinder bore, the grooves The width and depth can be set as required;

[0025] 3) Cylinder hole coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com