Construction material molding production line

A technology for building materials and production lines, applied in the direction of forming indenters, ceramic forming machines, ceramic forming workshops, etc., can solve the problems of inability to recycle construction waste, high production and manufacturing costs, low processing efficiency, etc., to achieve small intervention factors and processing. High efficiency and the effect of reducing the amount of soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The content of the present invention will be described below in conjunction with specific embodiments.

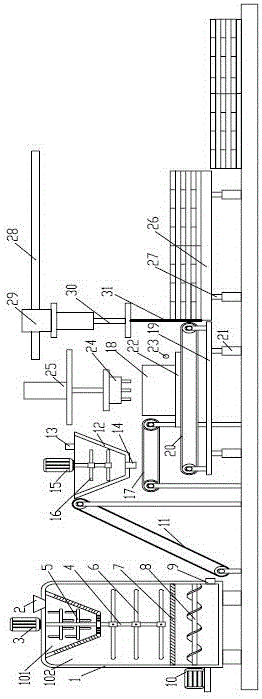

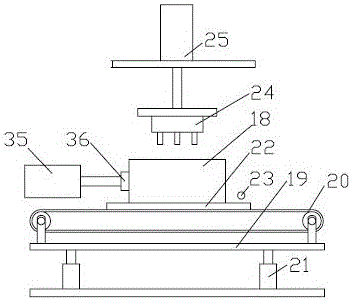

[0030] refer to figure 1 , a building material molding production line according to the present invention, comprising a feeding unit, a molding unit and a feeding unit;

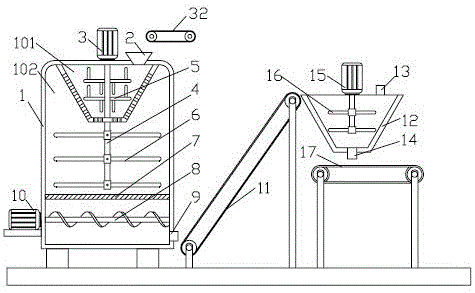

[0031] refer to figure 1 with figure 2 , the feeding unit includes a crushing mechanism, a first conveying mechanism, a mixing mechanism and a second conveying mechanism; the crushing mechanism is located at the feeding end of the first conveying mechanism, the mixing mechanism is located at the discharging end of the first conveying mechanism, and the second The second transmission mechanism is located at the discharge end of the mixing mechanism;

[0032] The crushing mechanism includes a crushing box 1, a first motor 3, a first crushing assembly 5, a second crushing assembly 6, a filter screen 7, a feeding screw 8 and a second motor 10; the crushing box 1 has a pre-crushing chamber 101 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com