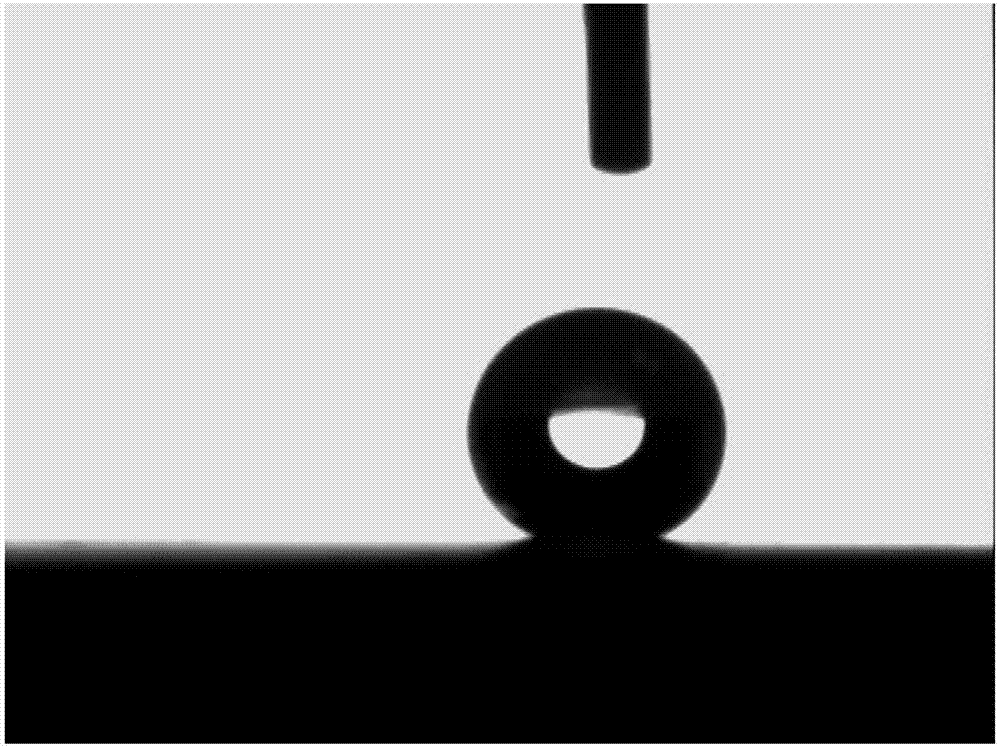

A kind of superhydrophobic silicon-aluminum-zirconium composite material and preparation method thereof

A super-hydrophobic, composite material technology, applied in the field of materials, can solve the problems of high brittleness, high preparation cost, unstable structure, etc., and achieve good wear resistance and mechanical resistance, low vibration mass loss rate, and stable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] SiO was prepared using the following steps 2 -Al 2 o 3 -ZrO 2 Airgel composites:

[0038] (1) Preparation of alumina sol. Weigh aluminum sulfate, ethanol, and deionized water with a molar ratio of 2:5:8, and stir thoroughly at room temperature to form a colorless and transparent solution.

[0039] (2) Silicon oxide and zirconium oxide. Weigh hexamethyldisilazane, zirconium chloride, ethanol, and deionized water with a molar ratio of 8:0.5:5:8, and fully stir at room temperature to form a colorless and transparent solution.

[0040](3) Preparation of ternary sol. Mix the above two sols, wherein the mass ratio of silicon oxide in the composite airgel to the silicon-aluminum-zirconium airgel is 80%, add a certain amount of propylene oxide, stir for 45 minutes, and stand still to obtain a ternary gel.

[0041] (4) Si-Al-Zr sol impregnated into fiber

[0042] The silica-aluminum-zirconium composite sol is immersed in the pretreated alumina fiber, and the mixture is p...

Embodiment 2

[0049] SiO was prepared using the following steps 2 -Al 2 o 3 -ZrO 2 Airgel composites:

[0050] (1) Preparation of alumina sol. Weigh aluminum sec-butoxide, ethanol, and deionized water with a molar ratio of 1:6:8, and stir fully at room temperature to form a colorless and transparent solution.

[0051] (2) Preparation of silica and zirconia sol. Weigh hexamethyldisilazane, zirconium chloride, ethanol, and deionized water with a molar ratio of 8:1:7:8, and fully stir at room temperature to form a colorless and transparent solution.

[0052] (3) Preparation of ternary sol. The above two sols were mixed, wherein the mass ratio of silicon oxide in the composite airgel to the silicon-aluminum-zirconium airgel was 90%, a certain amount of propylene oxide was added, stirred for 45 minutes, and the ternary gel was obtained by standing still.

[0053] (4) Si-Al-Zr sol impregnated into fiber

[0054] The silica-aluminum-zirconium composite sol is immersed in the pretreated alu...

Embodiment 3

[0061] SiO was prepared using the following steps 2 -Al 2 o 3 -ZrO 2 Airgel composites:

[0062] (1) Preparation of alumina sol. Weigh aluminum sec-butoxide, ethanol, and deionized water with a molar ratio of 1:5:8, and stir fully at room temperature to form a colorless and transparent solution.

[0063] (2) Silicon oxide and zirconium oxide. Weigh tetraethyl orthosilicate, trimethylchlorosilane, zirconium chloride, ethanol, and deionized water with a molar ratio of 3:5:0.5:6:10, and stir fully at room temperature to form a colorless transparent solution.

[0064] (3) Preparation of ternary sol. Mix the above two sols, wherein the mass ratio of silicon oxide in the composite airgel to the silicon-aluminum-zirconium airgel is 70%, add a certain amount of propylene oxide, stir for 60 minutes, and stand to obtain a ternary gel.

[0065] (4) Si-Al-Zr sol impregnated into fiber

[0066] The silicon-aluminum-zirconium composite sol is immersed in the pretreated silicon carbi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com