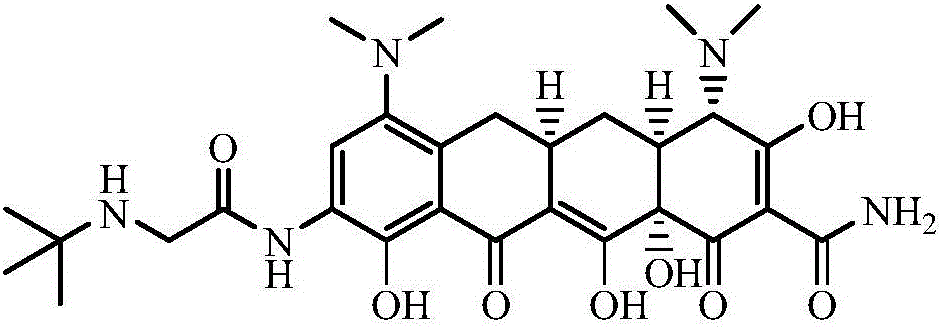

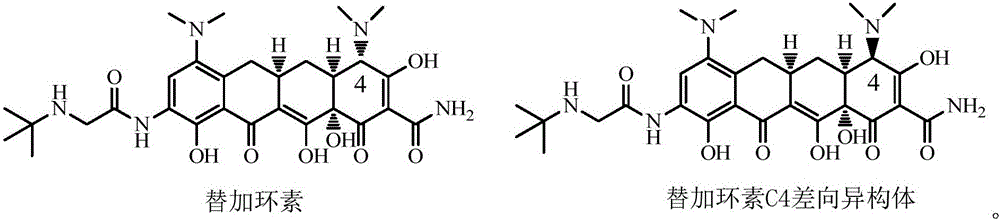

Method for preparing tigecycline intermediate

A Chinese compound technology, applied in the preparation of tigecycline intermediates and 9-nitrominocycline, can solve the problems of low purity, achieve simple operation, reduce the requirements of reaction equipment, and avoid corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

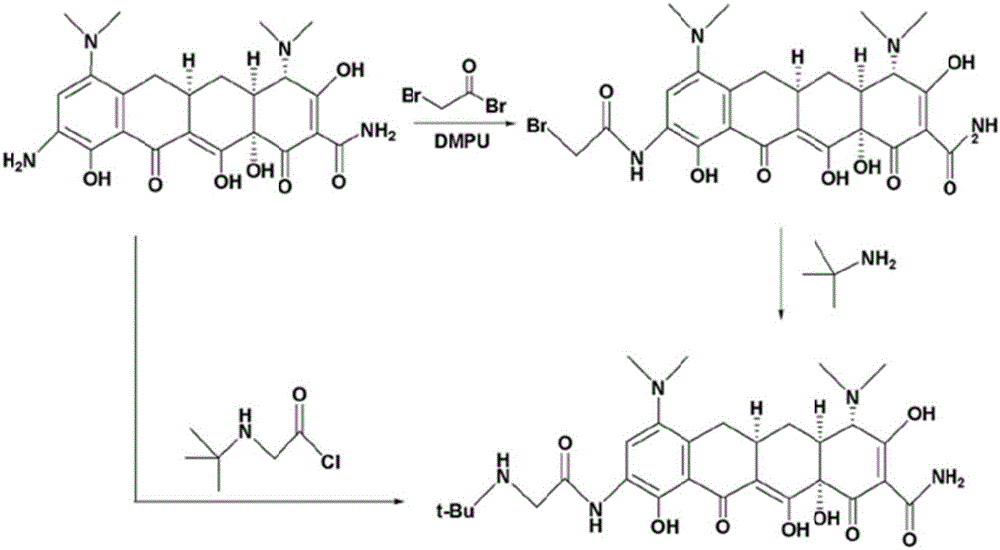

Method used

Image

Examples

Embodiment 1

[0035] Add concentrated sulfuric acid (180ml) into the reaction bottle, add minocycline hydrochloride (100g) at temperature control -20°C, and stir until it dissolves. Potassium nitrate (24.3 g) was added slowly and uniformly at a temperature of -20°C for 2.5 hours. After adding and keeping warm for 1 h, HPLC detection showed that the purity was 89.8%, and the C4-epimer was 0.2%. Control the temperature at -5°C and slowly add 10% ammonia methanol solution dropwise until no precipitation occurs, filter, and the filtrate is 9-nitrominocycline methanol solution. HPLC detection shows that the purity is 93.2%. 9-Nitrocycline C4-epimer of Kiminocycline 0.2%. The filtrate was concentrated to dryness under reduced pressure to obtain a solid, which was detected by HPLC, showing that the purity was 93.2%, and the C4-epimer of 9-nitrominocycline was 0.2%, which had no significant difference from that in the solution. The resulting solid residue on ignition was 0.05%.

[0036] It can b...

Embodiment 2

[0038] Add concentrated sulfuric acid (180ml) into the reaction bottle, add minocycline hydrochloride (90g) at temperature control -5°C, and stir until it dissolves. Potassium nitrate (25 g) was added slowly and uniformly at a temperature of -5°C for 2.5 hours. After adding and keeping warm for 1 hour, HPLC detection showed that the purity was 88.5%, and the C4-epimer of 9-nitrominocycline was 0.2%. Control the temperature at 0°C and slowly add 10% methanol solution of ammonia gas dropwise until no more precipitation occurs, filter, and the filtrate is 9-nitrominocycline methanol solution. HPLC detection shows that the purity is 92.1%, 9-nitrominocycline C4-epimer of minocycline 0.2%. The filtrate was concentrated to dryness under reduced pressure to obtain a solid, which was detected by HPLC, showing a purity of 92.0%, and a C4-epimer of 9-nitrominocycline of 0.2%. The resulting solid residue on ignition was 0.06%.

Embodiment 3

[0040] Add concentrated sulfuric acid (180ml) into the reaction bottle, add minocycline hydrochloride (60g) at -20°C under temperature control, and stir until it dissolves. Potassium nitrate (17 g) was added slowly and uniformly at a temperature of -15°C for 2.2 hours. After adding and keeping warm for 1 hour, HPLC detection showed that the purity was 89.1%, and the C4-epimer of 9-nitrominocycline was 0.2%. Control the temperature at -5°C and slowly add 10% ammonia methanol solution dropwise until no precipitation occurs, filter, and the filtrate is 9-nitrominocycline methanol solution. HPLC detection shows that the purity is 92.3%. 9-Nitrocycline C4-epimer of Kiminocycline 0.2%. The filtrate was concentrated to dryness under reduced pressure to obtain a solid, which was detected by HPLC, showing a purity of 92.4%, and a C4-epimer of 9-nitrominocycline of 0.2%. The resulting solid residue on ignition was 0.04%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com