Automobile storage battery case material with flame-retardant effect and preparation method thereof

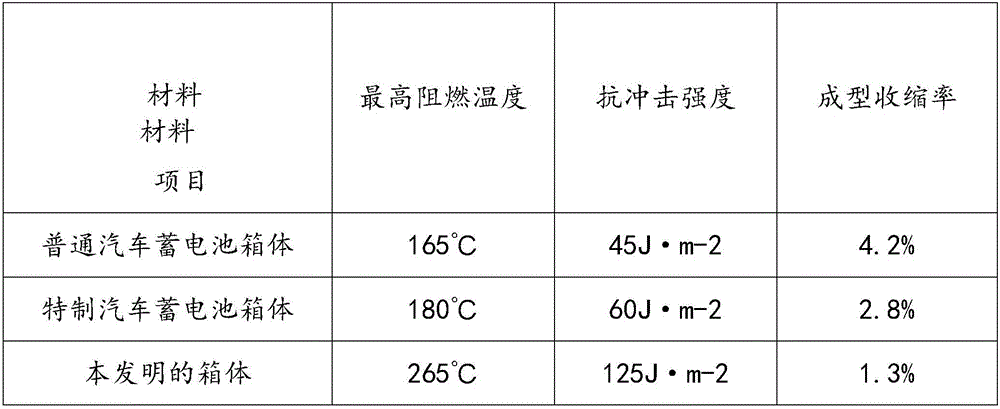

A box material and battery technology, which is applied in the field of automobile battery box materials and its preparation, can solve the problems of low impact strength, poor flame retardant effect, large molding shrinkage rate, etc., and achieves small molding shrinkage rate and improved The effect of structural firmness and high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A car battery box material with a flame-retardant effect, made of the following materials in parts by weight, including 35 parts of polypropylene, 6 parts of polysulfone, 20 parts of polyaryletherketone, 8 parts of graphite, and 14 parts of glass fiber , 7 parts of PVC resin, 6 parts of vinyl acetate resin, 10 parts of linoleic acid, 3 parts of chromium oxide, 5 parts of boric acid, 8 parts of polycaprolactone polyol, 9 parts of N-butylphenylsulfonamide, titanic acid 13 parts of potassium whiskers, 7 parts of polyethylene glycol, 14 parts of 4,4'-biphenylene, 6 parts of polyolefin fiber, 16 parts of polyester fiber, 8 parts of microencapsulated red phosphorus and 7 parts of aluminum hydroxide .

[0020] A method for preparing a car battery box material with a flame-retardant effect, comprising the following steps:

[0021] 1) 35 parts of polypropylene, 6 parts of polysulfone, 20 parts of polyarylether ketone, 8 parts of graphite, 14 parts of glass fiber, 7 parts of PVC...

Embodiment 2

[0028] A car battery box material with a flame-retardant effect, made of the following materials in parts by weight, including 39.5 parts of polypropylene, 9 parts of polysulfone, 22.5 parts of polyaryletherketone, 9 parts of graphite, and 15 parts of glass fiber , 8.5 parts of PVC resin, 7.5 parts of vinyl acetate resin, 12 parts of linoleic acid, 5.5 parts of chromium oxide, 7.5 parts of boric acid, 10 parts of polycaprolactone polyol, 9.5 parts of N-butylphenylsulfonamide, titanic acid 14 parts of potassium whiskers, 7.5 parts of polyethylene glycol, 16 parts of 4,4'-biphenylene, 8 parts of polyolefin fiber, 19 parts of polyester fiber, 11 parts of microencapsulated red phosphorus and 10.5 parts of aluminum hydroxide .

[0029] A method for preparing a car battery box material with a flame-retardant effect, comprising the following steps:

[0030] 1) 39.5 parts of polypropylene, 9 parts of polysulfone, 22.5 parts of polyaryletherketone, 9 parts of graphite, 15 parts of gla...

Embodiment 3

[0037] A car battery box material with a flame-retardant effect, made of the following materials in parts by weight, including 44 parts of polypropylene, 12 parts of polysulfone, 25 parts of polyaryletherketone, 10 parts of graphite, and 16 parts of glass fiber , 10 parts of PVC resin, 9 parts of vinyl acetate resin, 14 parts of linoleic acid, 8 parts of chromium oxide, 10 parts of boric acid, 12 parts of polycaprolactone polyol, 10 parts of N-butylphenylsulfonamide, titanic acid Potassium whiskers 15 parts, polyethylene glycol 8 parts, 4,4'-biphenylene 18 parts, polyolefin fiber 10 parts, polyester fiber 22 parts, microencapsulated red phosphorus 14 parts and aluminum hydroxide 14 parts .

[0038] A method for preparing a car battery box material with a flame-retardant effect, comprising the following steps:

[0039] 1) 44 parts of polypropylene, 12 parts of polysulfone, 25 parts of polyarylether ketone, 10 parts of graphite, 16 parts of glass fiber, 10 parts of PVC resin, 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com