Varnish for tin plate ink

A technology of iron printing ink and varnish, which is applied in coatings, epoxy resin coatings, polyester coatings, etc., can solve the problems of easy corrosion of the surface by solvents, poor chemical resistance of products, high energy consumption of varnish, etc., and achieve short curing cycle , good solvent resistance and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

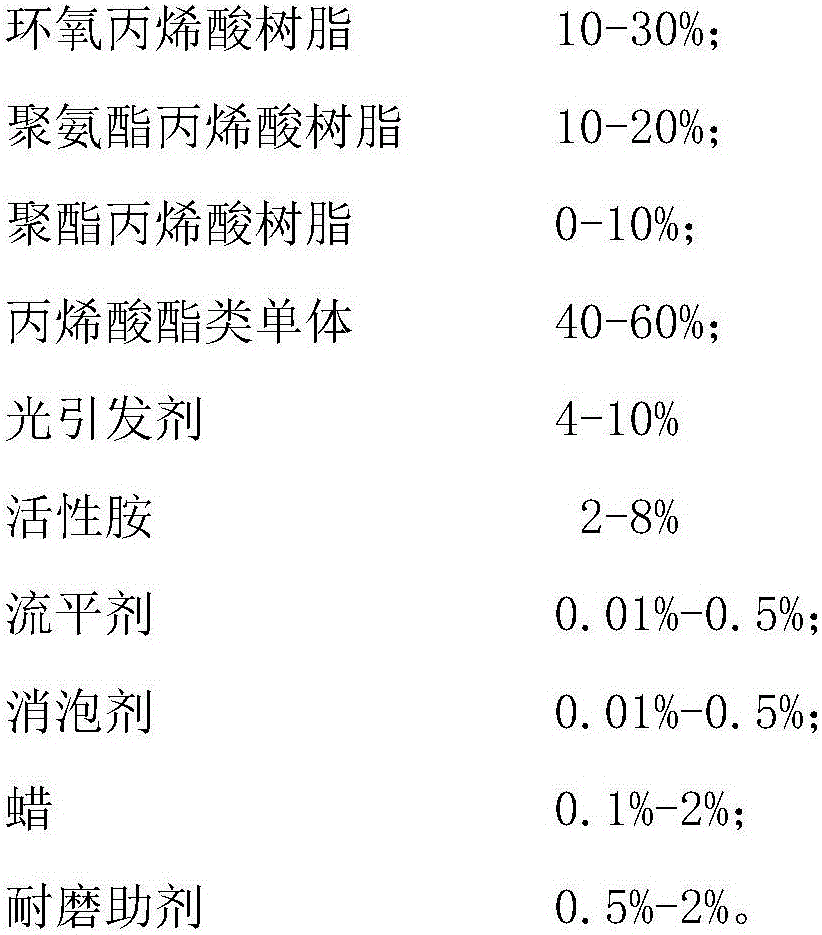

[0028] The invention provides a kind of varnish used on iron printing ink, which consists of the following components by mass percentage:

[0029]

[0030]

Embodiment 2

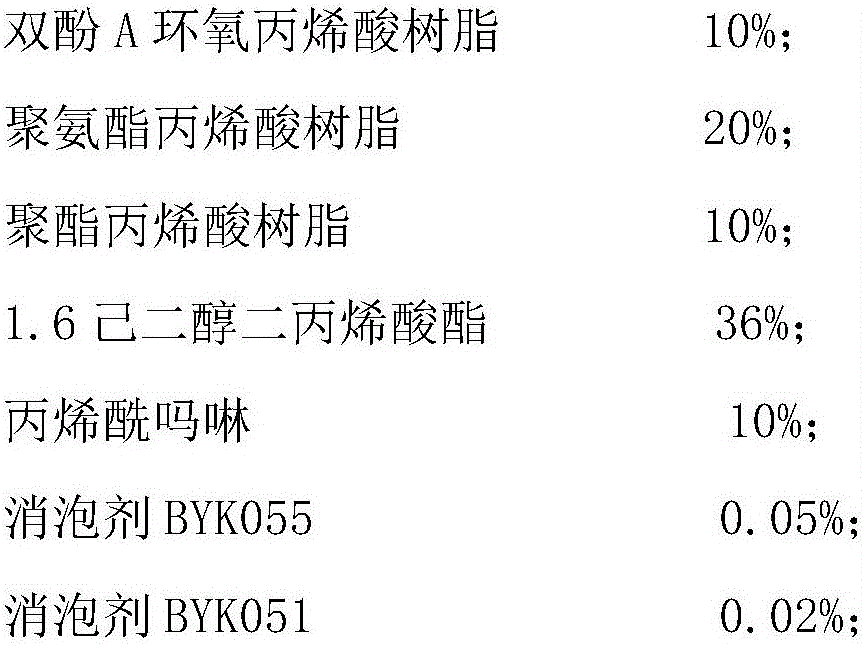

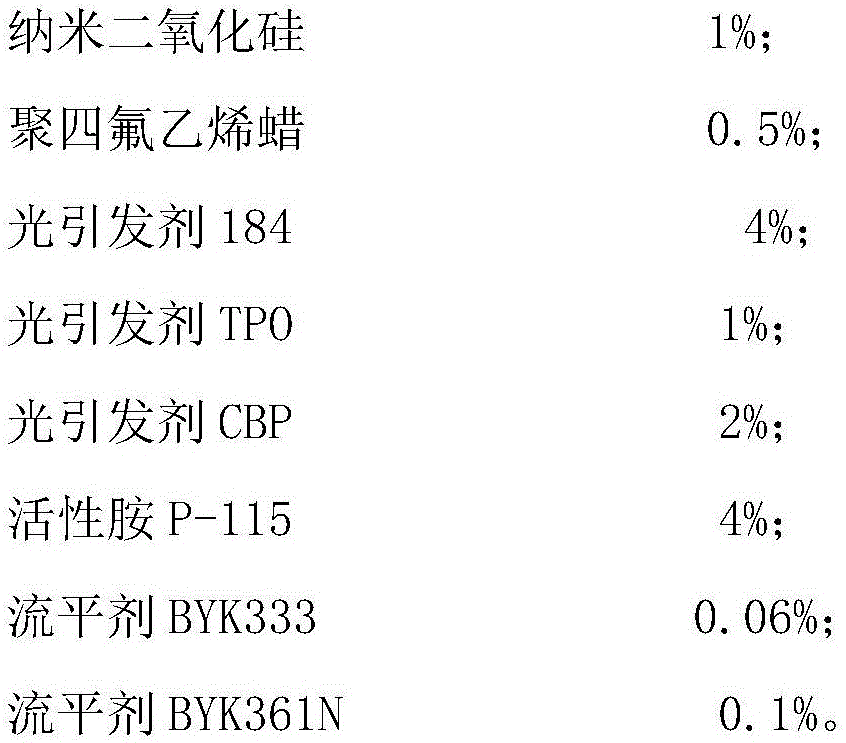

[0032] The invention provides a kind of varnish used on iron printing ink, which consists of the following components by mass percentage:

[0033]

Embodiment 3

[0035] The invention provides a kind of varnish used on iron printing ink, which consists of the following components by mass percentage:

[0036]

[0037] The preparation method of above-mentioned each varnish comprises the following steps:

[0038] (11) Mix photoinitiator and acrylate monomer, heat at 60°C, and start stirring until clear;

[0039] (12) Add epoxy acrylic resin, polyester acrylic resin, polyurethane acrylic resin, and stir until transparent at 60°C;

[0040] (13) Add leveling agent, defoamer, and wear-resistant additives to disperse;

[0041] (14) Add wax and stir at high speed until it is evenly dispersed to obtain the finished product.

[0042] The test data of the varnish of above-mentioned embodiment 1,2,3 of the present invention is as follows table:

[0043] Table 1

[0044]

[0045]

[0046] In summary, the varnish of the present invention has strong adhesion, good processability and chemical resistance, and is more environmentally friendly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com