Process for preparing maltose by high-temperature liquification method

A technology of maltose and high temperature, which is applied in the field of high temperature liquefaction to prepare maltose, can solve the problems of amylase, such as great influence of temperature and humidity, poor filtering performance of sugar solution, and increased production cost, to achieve good effect, save high temperature amylase, increase cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

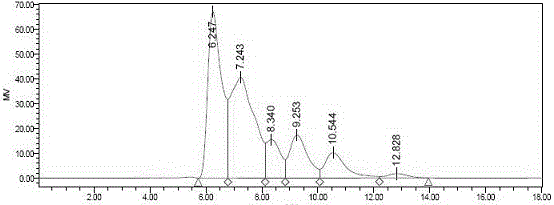

Embodiment 1

[0020] The process for preparing maltose by high-temperature liquefaction method in this embodiment comprises the following steps:

[0021] 1) Sizing: Sizing starch and water to 18 degrees Baume, the mass ratio of starch and water is 9:16, to obtain a mixed starch slurry;

[0022] 2) Liquefaction: Adjustment step 1) Use sulfuric acid to adjust the pH of the mixed starch slurry to 3.0, the temperature of one injection is 150°C, the pressure is 0.3MPa, the maintenance time is 12 minutes, and the DE value of the liquefaction solution is 16%;

[0023] 3) Saccharification: Add fungal enzymes to the liquefaction solution in step 2) at a dry basis of 0.2kg / ton to obtain a saccharification solution with a disaccharide content of more than 40%;

[0024] 4) Filtration and decolorization: add diatomaceous earth to the saccharification solution in step 3), the amount of diatomite added is 1.5kg / ton dry basis, filter with a plate and frame, the temperature of the filtrate is 65°C, and the ...

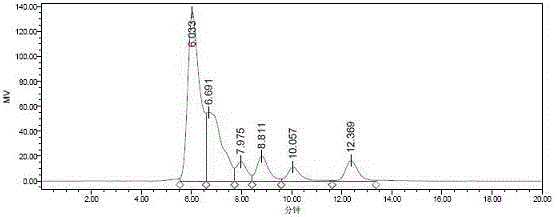

Embodiment 2

[0035] The process for preparing maltose by high-temperature liquefaction method in this embodiment comprises the following steps:

[0036] 1) Sizing: starch and water are slurried to 19 degrees Baume, the mass ratio of starch and water is 1:2, and a mixed starch slurry is obtained;

[0037] 2) Liquefaction: Adjustment step 1) Use sulfuric acid to adjust the pH of the mixed starch slurry to 3.5, the temperature of one injection is 155°C, the pressure is 0.35MPa, the maintenance time is 15 minutes, and the DE value of the liquefaction solution is 18%;

[0038] 3) Saccharification: Add fungal enzymes to the liquefaction solution in step 2) at a rate of 0.2-0.3 kg / ton dry basis to obtain a saccharification solution with a disaccharide content of more than 40%;

[0039] 4) Filtration and decolorization: add diatomaceous earth to the saccharification solution in step 3), the amount of diatomite added is 1.5kg / ton dry basis, filter with a plate and frame, the temperature of the filt...

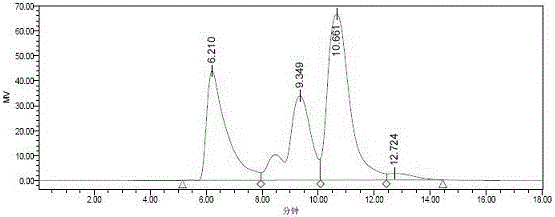

Embodiment 3

[0043] The process for preparing maltose by high-temperature liquefaction method in this embodiment comprises the following steps:

[0044] 1) Sizing: starch and water are slurried to 20 degrees Baume, the mass ratio of starch and water is 3:7, and a mixed starch slurry is obtained;

[0045] 2) Liquefaction: Adjustment step 1) Use sulfuric acid to adjust the pH of the mixed starch slurry to 3.5, the temperature of one injection is 160°C, the pressure is 0.4MPa, the maintenance time is 20 minutes, and the DE value of the liquefaction solution is 20%;

[0046] 3) Saccharification: add fungal enzymes to the liquefaction solution in step 2) at a dry basis of 0.3kg / ton to obtain a saccharification solution with a disaccharide content of more than 40%;

[0047] 4) Filtration and decolorization: add diatomaceous earth to the saccharification solution in step 3), the amount of diatomite added is 1.5kg / ton dry basis, filter with a plate and frame, the temperature of the filtrate is 70°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com