Aluminum alloy strip

A technology for aluminum alloy strips and impurities, applied in the field of aluminum alloys, can solve the problems of inability to meet the needs of high-strength use, low tensile strength and yield strength, and poor processing performance, so as to improve corrosion resistance and processing performance. , the effect of processing performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

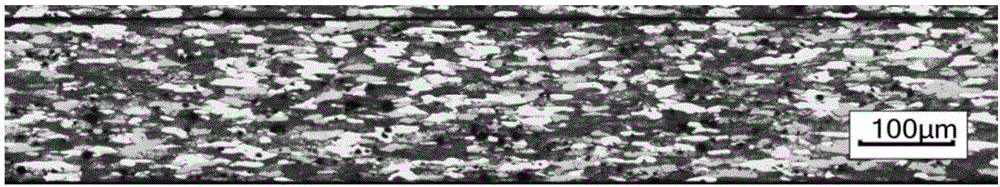

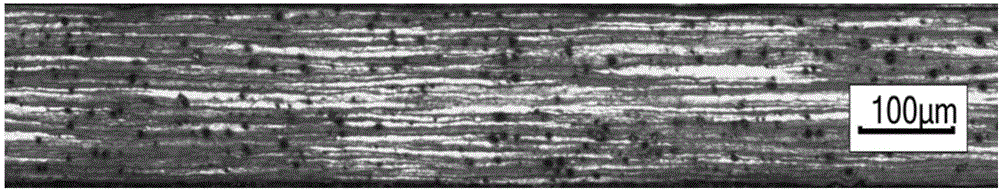

Image

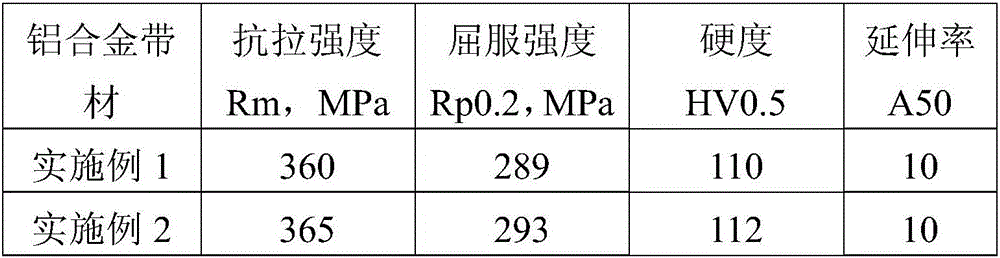

Examples

Embodiment 1

[0036] The composition of the aluminum alloy strip in this embodiment is: Si: 0.02wt%, Fe: 0.2wt%, Mn: 0.25wt%, Mg: 5.2wt%, and the balance is Al and unavoidable impurities.

[0037] The aluminum alloy strip material of the present embodiment can be made by following method:

[0038] 1. Manufacture ingot

[0039]According to the set composition, after melting industrial pure aluminum ingots, add pure magnesium ingots, aluminum-manganese master alloys, aluminum-iron master alloys, aluminum-silicon master alloys, melt and purify, degas and then melt and cast to obtain a size of 560mm*1420mm*5200mm wherein, the composition of the ingot is: Si: 0.02wt%, Fe: 0.2wt%, Mn: 0.25wt%, Mg: 5.2wt%, and the balance is Al and unavoidable impurities.

[0040] When manufacturing ingots, the process control conditions are: refining temperature 740°C; casting speed 45mm / min, water flow 210m 3 / h, the casting temperature is 680°C; in addition, in the manufacture of ingots, the grain size should...

Embodiment 2

[0059] The composition of the aluminum alloy strip in this embodiment is: Si: 0.10wt%, Fe: 0.15wt%, Mn: 0.23wt%, Mg: 5.3wt%, and the balance is Al and unavoidable impurities.

[0060] The aluminum alloy strip material of the present embodiment can be made by following method:

[0061] 1. Manufacture ingot

[0062] According to the set composition, after melting industrial pure aluminum ingots, add pure magnesium ingots, aluminum-manganese master alloys, aluminum-iron master alloys, aluminum-silicon master alloys, melt and purify, degas and then melt and cast to obtain a size of 560mm*1420mm*5200mm wherein, the composition of the ingot is: Si: 0.10wt%, Fe: 0.15wt%, Mn: 0.23wt%, Mg: 5.3wt%, and the balance is Al and unavoidable impurities.

[0063] When manufacturing ingots, the process control conditions are: refining temperature 735°C; casting speed 40mm / min, water flow 200m 3 / h, the casting temperature is 665°C; in addition, in the manufacture of ingots, the grain size sho...

Embodiment 3

[0082] The composition of the aluminum alloy strip in this embodiment is: Si: 0.08wt%, Fe: 0.1wt%, Mn: 0.18wt%, Mg: 5.4wt%, and the balance is Al and unavoidable impurities.

[0083] The aluminum alloy strip material of the present embodiment can be made by following method:

[0084] 1. Manufacture ingot

[0085] According to the set composition, after melting industrial pure aluminum ingots, add pure magnesium ingots, aluminum-manganese master alloys, aluminum-iron master alloys, aluminum-silicon master alloys, melt and purify, degas and then melt and cast to obtain a size of 560mm*1420mm*5200mm wherein, the composition of the ingot is: Si: 0.08wt%, Fe: 0.1wt%, Mn: 0.18wt%, Mg: 5.4wt%, and the balance is Al and unavoidable impurities.

[0086] When manufacturing ingots, the process control conditions are: refining temperature 750°C; casting speed 50mm / min, water flow 220m 3 / h, the casting temperature is 690°C; in addition, when making ingots, the grain size should be contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com