Low and ultra-low permeable reservoir CO2 drive near-miscible pressure area determining method

A technology of miscible pressure and area determination, which is applied in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problems of unclear judgment and understanding of near-miscible flooding conditions, and achieve the effect of true and reliable measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

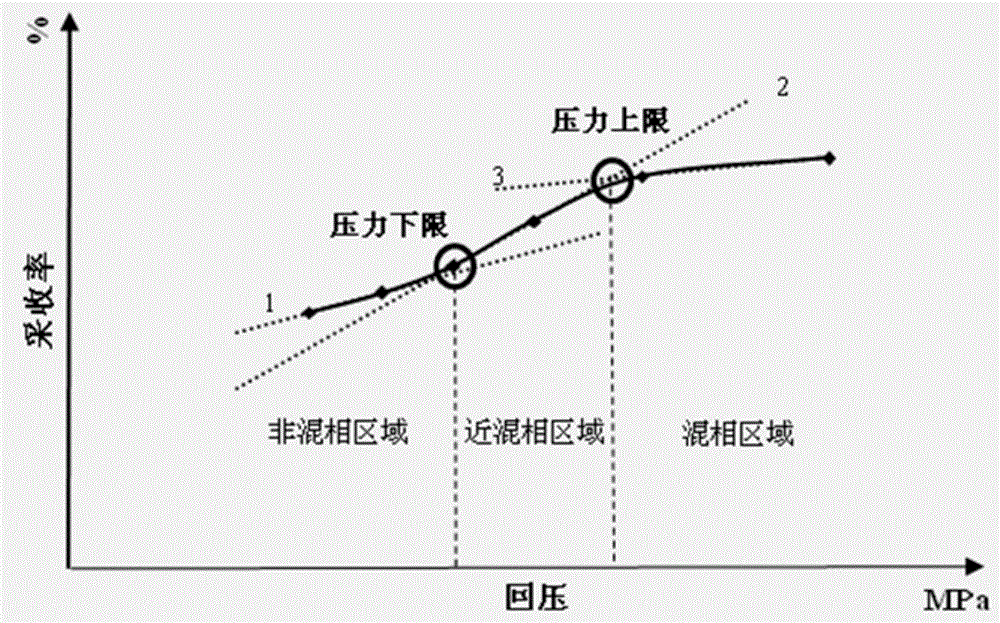

AI Technical Summary

Problems solved by technology

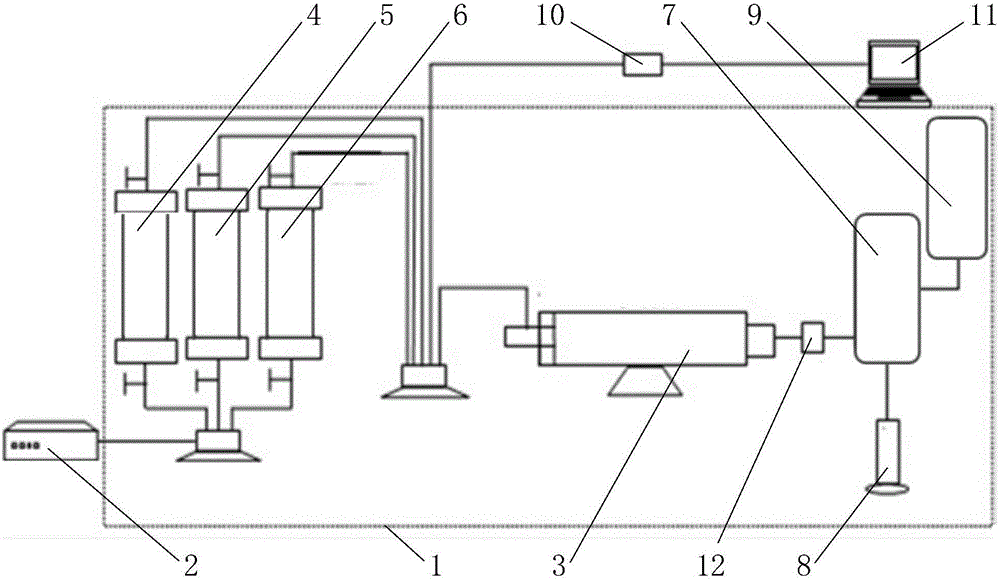

Method used

Image

Examples

Embodiment 1

[0058] In this embodiment, according to the mineral composition of formation water and injection water in the target block, the formation water and injection water in the target oilfield block are used to prepare simulated water-based injection water for the experiment. The total salinity of the water is 80063.14mg / L, The hardness is 4905.79mg / L; according to the well fluid composition of the sampling well in the target oilfield block, the degassed and dehydrated crude oil in the target oilfield block is mixed with hydrocarbon gas in a certain proportion to prepare simulated oil, and the simulated oil viscosity is 2.38mPa·s ; using high-purity CO 2 As the injected gas, the purity of the gas is 99.99%; the formation temperature of the target oilfield block is 60°C.

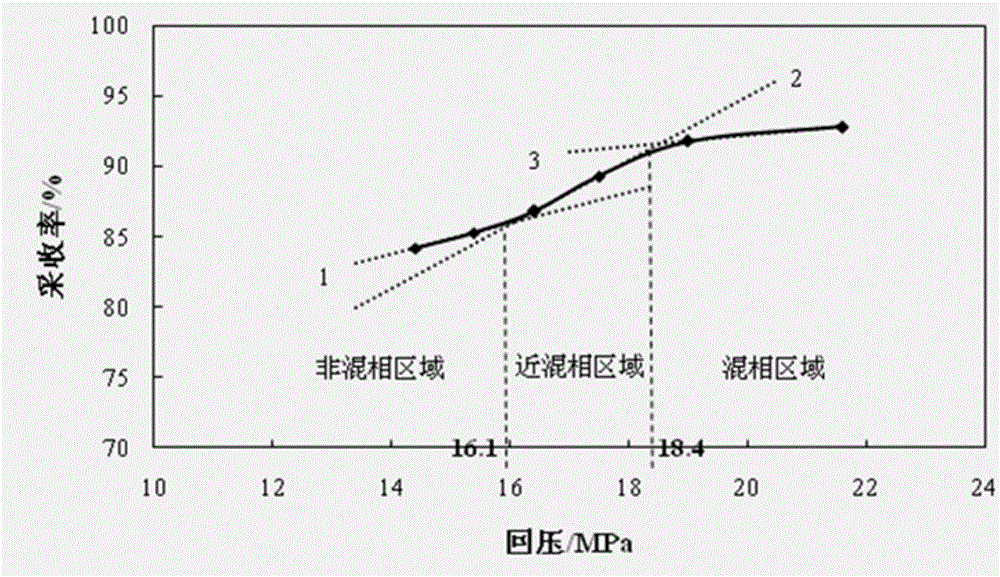

[0059] Adopt a kind of low, ultra-low permeability reservoir CO of the present invention 2 A method for determining the area of near-miscible pressure during flooding, and determining the CO content of the targe...

Embodiment 2

[0075] In the present embodiment, adopt the method of the present invention to determine the CO 2 When driving close to the miscible pressure area, the size of the physical model core used is 50×4.5×4.5cm 3 ;Other experimental conditions, experimental materials and concrete steps are basically the same as in Example 1, and CO under different displacement pressures and back pressure conditions is obtained. 2 The specific experimental results are shown in Table 2; the CO 2 The relationship curve between flooding recovery and back pressure, such as Figure 4 shown.

[0076] Table 2 50cm long core CO 2 The relationship between flooding recovery and back pressure (20×10 -3 μm 2 )

[0077]

[0078] It can be seen from Table 2 that the physical properties of the low-permeability core reservoirs in each experimental group are roughly the same, and the gas permeability is 20×10 -3 μm 2 , the core porosity is between 15% and 19%, and the original oil saturation is between 33%...

Embodiment 3

[0083] In the present embodiment, adopt the method of the present invention to determine the CO 2 When driving close to the miscible pressure area, the size of the physical model core used is 80×4.5×4.5cm 3 ;Other experimental conditions, experimental materials and concrete steps are basically the same as in Example 1, and CO under different displacement pressures and back pressure conditions is obtained. 2 The specific experimental results are shown in Table 3; the CO 2 The relationship curve between flooding recovery and back pressure, such as Figure 5 shown.

[0084] Table 3 80cm long core CO 2 The relationship between flooding recovery and back pressure (20×10 -3 μm 2 )

[0085]

[0086] It can be seen from Table 3 that the physical properties of the low-permeability core reservoirs in each experimental group are roughly the same, and the gas permeability is 20×10 -3 μm 2 , the core porosity is between 14% and 18%, and the original oil saturation is between 36%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Core permeability | aaaaa | aaaaa |

| Total salinity | aaaaa | aaaaa |

| Gas permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com