Coal-water slurry feeding device and boiler for multi-process circulating fluidized bed boiler

A circulating fluidized bed and feeding device technology, which is applied in the boiler field, can solve the problems that coal-water slurry particles are difficult to fully burn, coal-water slurry combustion is prone to slagging, and drop-shaped coal-water slurry is unevenly distributed. Disaggregation, cost saving, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

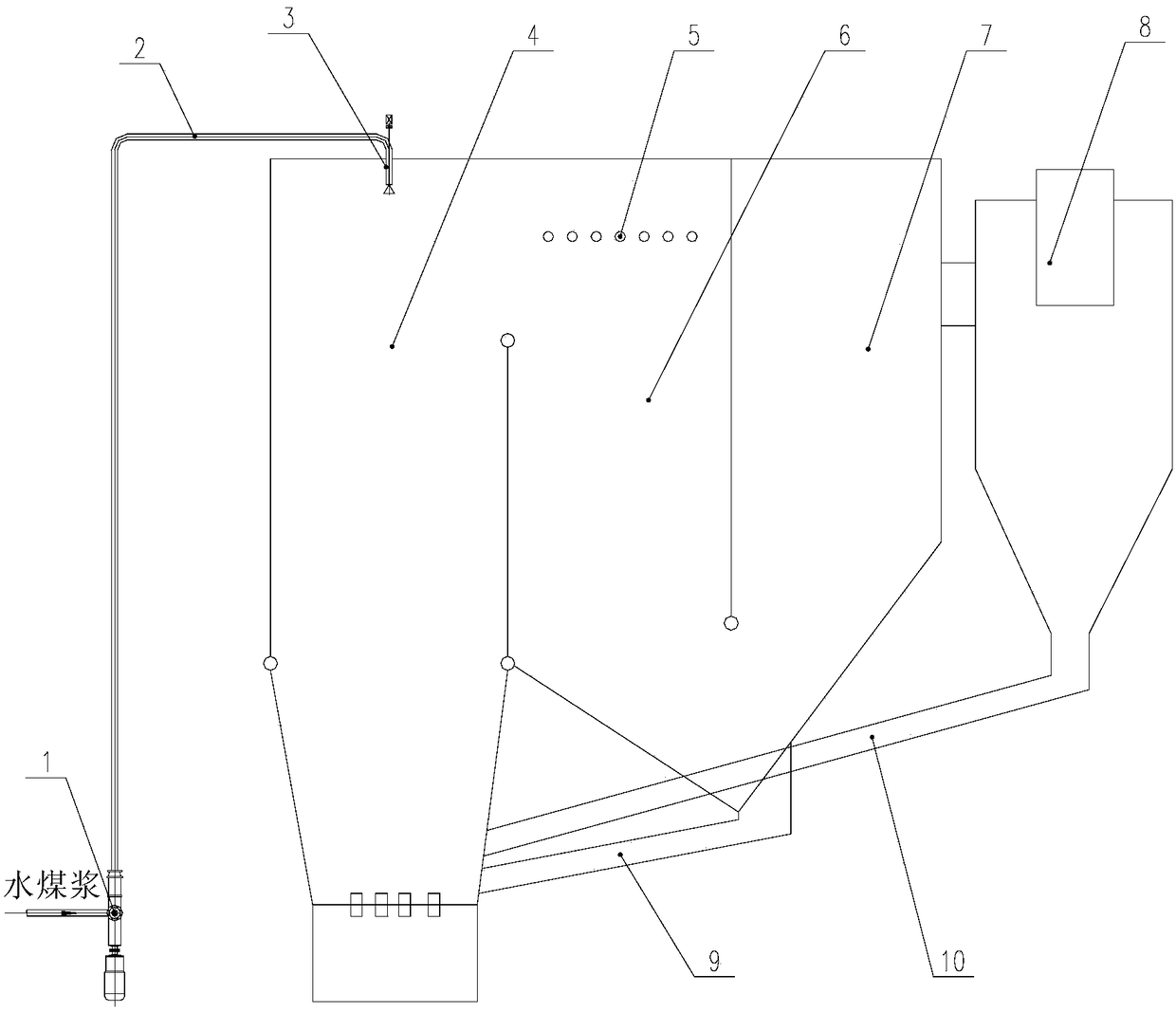

[0059] Embodiment 1 of the present invention provides a multi-process circulating fluidized bed boiler, which adopts the second fluidization-suspension efficient and clean combustion mode for the supplied coal-water slurry fuel. The structure of Embodiment 1 of the present invention is as follows figure 1 shown, including:

[0060] Slurry supply pump 1, slurry supply pipe 2, coal water slurry granulator 3, main combustion chamber 4, secondary tuyere 5, auxiliary combustion chamber 6, burnout chamber 7, separator 8, primary return pipe 9, secondary Grade return pipe 10.

[0061] The main combustion chamber 4, the secondary combustion chamber 6 and the burnout chamber 7 are arranged side by side in sequence; the separator 8 is arranged behind the flue gas outlet of the burnout chamber 7; the primary return pipe 9 is arranged in the secondary combustion chamber 6 and the burnout chamber 7 to the bottom of the secondary combustion chamber 6 and the burnout chamber 7 to the dense...

Embodiment 2

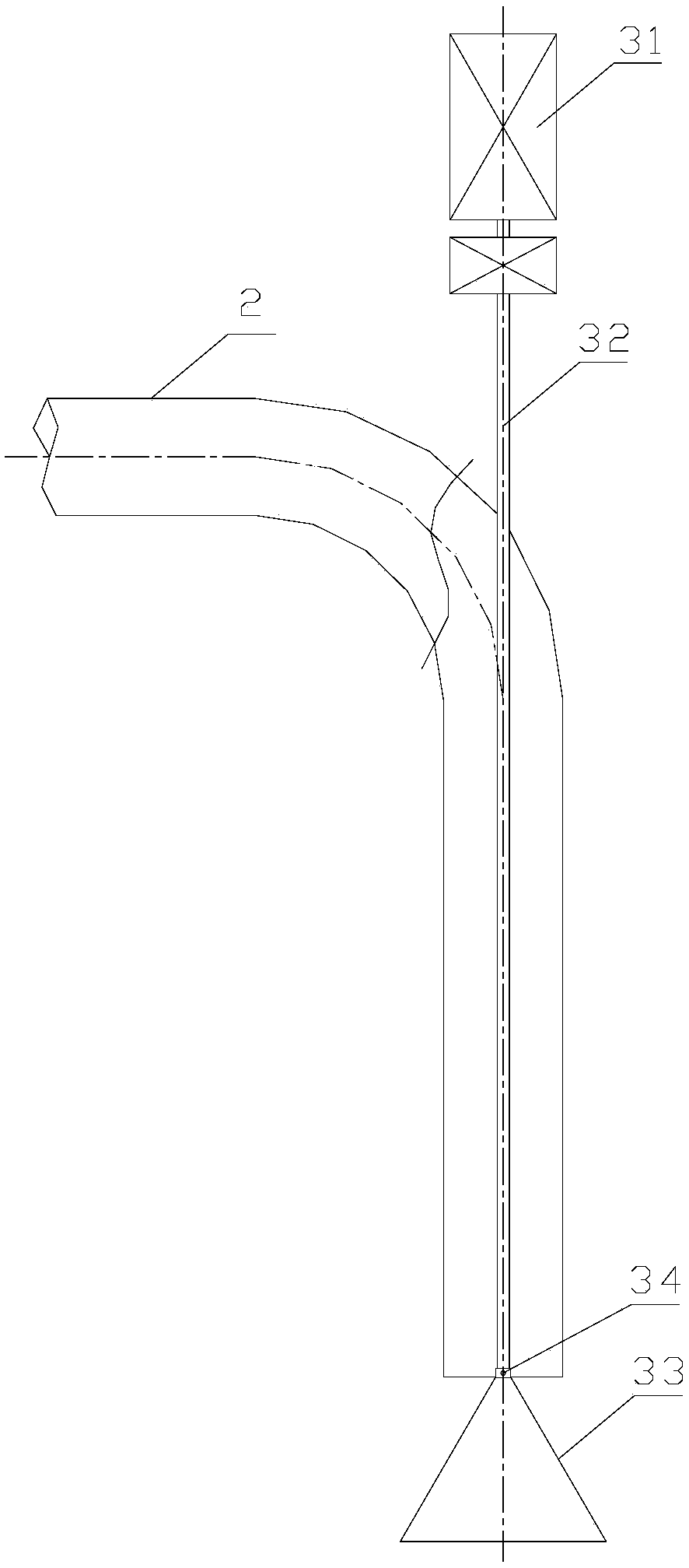

[0076] Embodiment 2 of the present invention provides a coal-water slurry feeding device for a multi-process circulating fluidized bed, which is applied to a multi-process circulating fluidized bed boiler. The multi-process circulating fluidized bed boiler includes: a main combustion chamber 4, Secondary combustion chamber 6, burnout chamber 7, separator 8. The main combustion chamber 4, the secondary combustion chamber 6 and the burnout chamber 7 are arranged side by side in sequence; the separator 8 is arranged behind the flue gas outlet of the burnout chamber 7; Devices include:

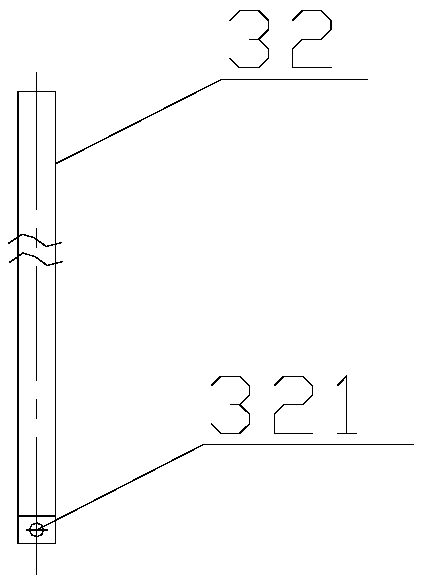

[0077] Slurry pump 1, slurry supply pipe 2, coal water slurry granulator 3 and secondary air outlet 5. The secondary air outlet 5 is arranged at the position near the top of the side walls of the secondary combustion chamber 6; the coal-water slurry granulator 3 includes: a driving part 31, a moving part 32 and a spreader 33; the moving part 32 is driven to rotate by the driving part 31 , the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com