Pigment color paste and preparation method thereof, and pigment ink

A technology of pigment color paste and pigment ink, which is applied in the direction of pigment paste, ink, household appliances, etc., and can solve the problems of self-aggregation, poor adhesion of water-based printing materials, fast-drying substrates, ink accumulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

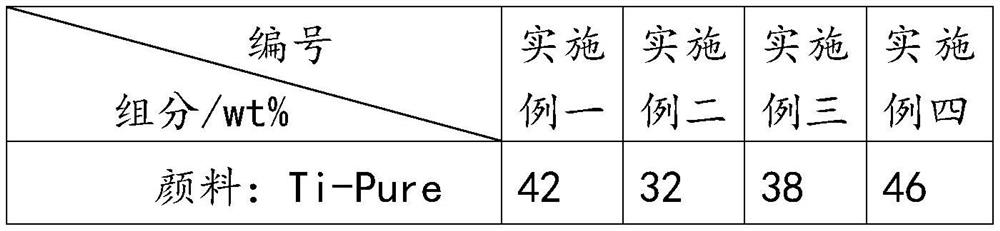

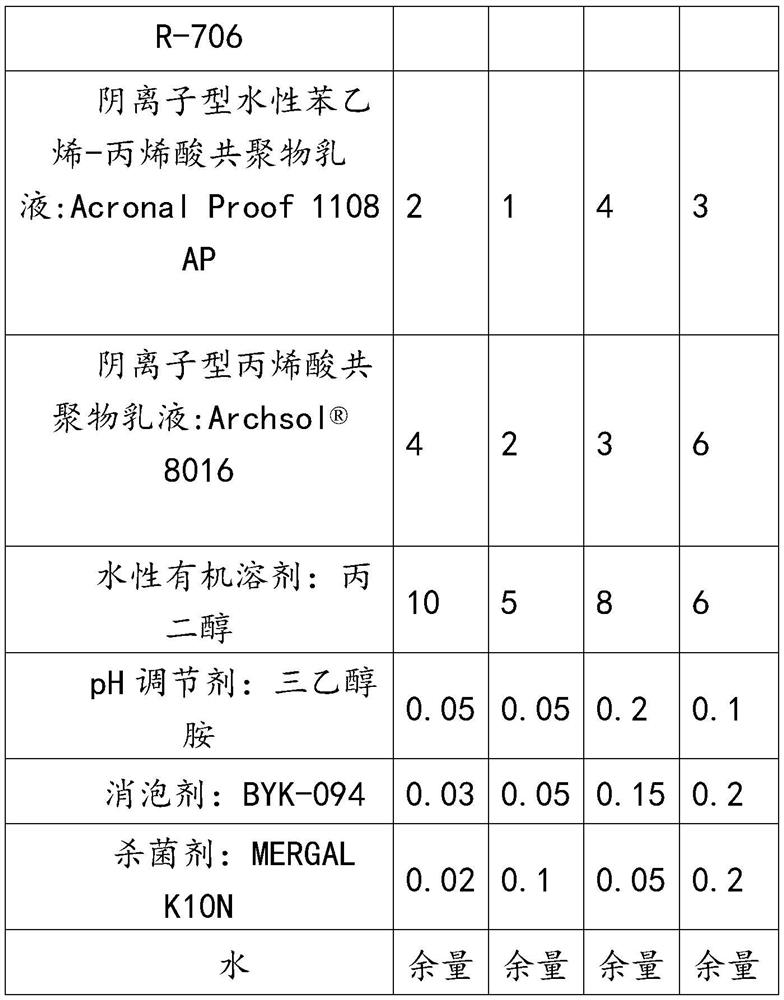

[0029] The preparation method of pigment mill paste comprises the following steps:

[0030] a. Divide the water into two parts, mix 40% pigment, 8% aqueous organic solvent and part of the water in proportion at room temperature at a speed of 800rpm-1200rpm for 30min-60min, and grind at a speed of 2000rpm-2500rpm 1h~2h, get the first dispersion liquid;

[0031] b. In proportion, mix 7% dispersant, 3% additives, another part of water and the first dispersion obtained in step a at room temperature at a speed of 800rpm-1200rpm for 1h-2h to obtain the second dispersion;

[0032] c. Grind the second dispersion at room temperature and at a speed of 1500rpm to 2000rpm for 4h to 6h, then centrifuge at a speed of 6000rpm to 8000rpm for 10min to 20min, and then filter through a 1.0μm pore size filter membrane to obtain the filtrate.

[0033] When grinding in step a and step c, grinders are used respectively, wherein the filling amount of zirconium beads in the grinder is 70% to 80%, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com