Optical film material, method for preparing same, display substrate and display device

An optical film and display substrate technology, applied in optics, optical components, optical components, etc., can solve the problem of small viewing angle, only see all black or white, can not see color, etc., to maintain brightness, expand The effect of the angle range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

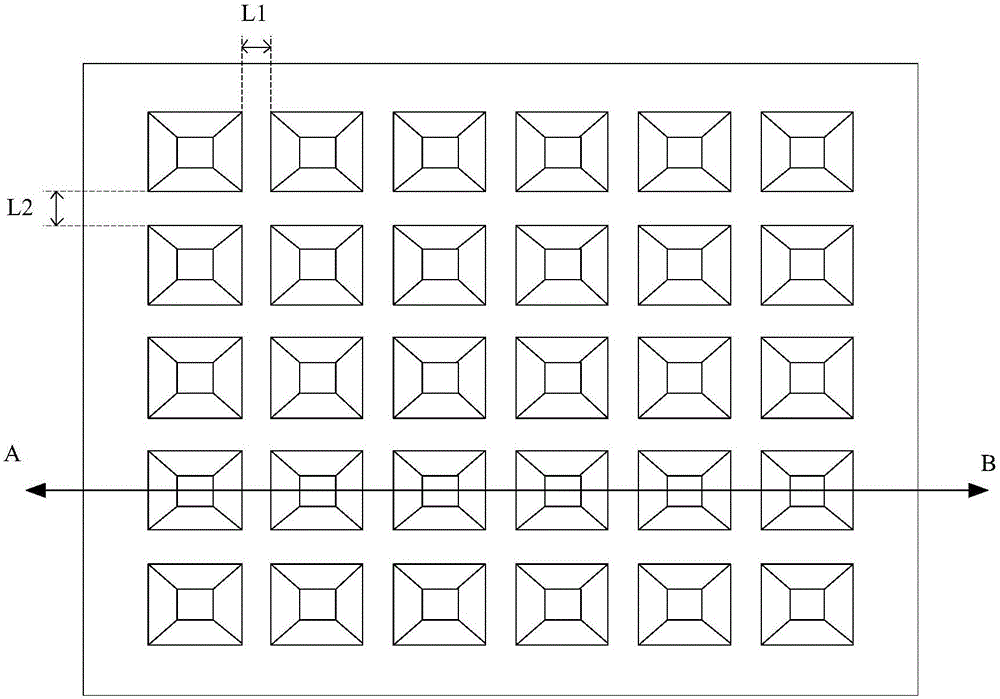

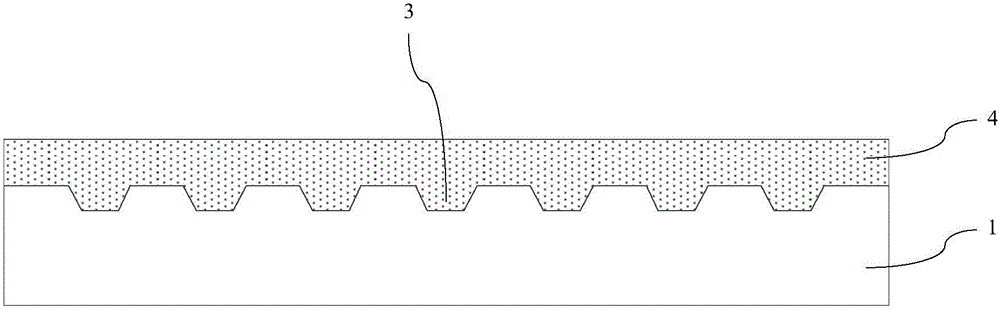

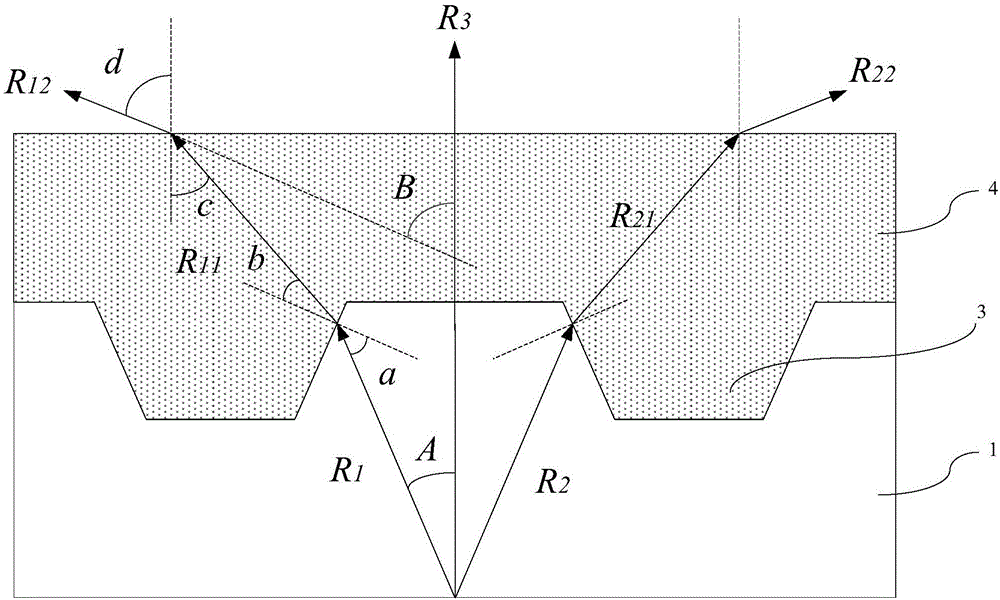

[0035] Such as figure 1 and 2 As shown, this embodiment provides an optical film material, which includes: a substrate 1 and a planarization layer 4; a groove 3 is provided on the substrate 1, and the cross-sectional area of the groove 3 is parallel to the plane where its bottom surface is located, along the The direction away from the bottom surface gradually increases; the planarization layer 4 is located on the side of the substrate 1 with the groove 3 , and the refractive index of the planarization layer 4 is greater than that of the substrate 1 . The planarization layer 4 at least fills up the groove 3 , and the surface of the planarization layer 4 is flat.

[0036] Specifically, the optical film material in this embodiment can be applied to a display substrate, and the display substrate can be boxed with an array substrate to form a display panel, and the optical film material is located on the light-emitting surface side of the display panel; the display substrate ca...

Embodiment 2

[0045] Such as Figure 5As shown, this embodiment provides a method for preparing an optical film, and the display substrate may be the optical film in Embodiment 1. The preparation method includes: etching the substrate 1 to form a groove 3, and the angle between the side surface and the bottom surface of the groove 3 is an acute angle; forming a planarization layer on the substrate 1 on which the groove 3 is formed. 4.

[0046] The steps for preparing the optical film are described in detail below.

[0047] Step 1: Coating a photoresist 2 on the substrate 1, exposing and developing to form a photoresist reserved area 21 and a photoresist unreserved area.

[0048] Step 2: Etching the non-retained photoresist area using plasma etching equipment to form the groove 3 .

[0049] This step specifically includes: using ICP plasma etching equipment, using Ar and CHF 3 The mixed gas is an etching gas to etch the substrate 1, specifically, the Ar inert gas is ionized into Ar in th...

Embodiment 3

[0054] This embodiment provides a display device, which includes the display substrate in Embodiment 1. Therefore, the display device of this embodiment has a wider viewing angle and better display effect.

[0055] Wherein, the display device can be a liquid crystal display device or an electroluminescent display device, such as a liquid crystal panel, an electronic paper, an OLED panel, a mobile phone, a tablet computer, a TV set, a monitor, a notebook computer, a digital photo frame, a navigator, etc. product or part. Figure 6 Shown in is a liquid crystal display device, which includes an array substrate and a color filter substrate, and a liquid crystal layer 7 arranged between the array substrate and the color filter substrate, wherein the display substrate in Embodiment 1 is also Figure 6 The color filter substrate specifically includes a base 1 with grooves 3 , a planarization layer 4 , a color filter layer 9 , and an alignment layer 8 ; the array substrate includes a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com