An anti-integral windup control method for motor control

A technology of motor control and control method, applied in general control system, adaptive control, control/regulation system, etc., can solve problems such as maintaining or reducing integral action, disturbance, and slow integral accumulation speed, so as to improve adaptability and overall The effect of controlling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

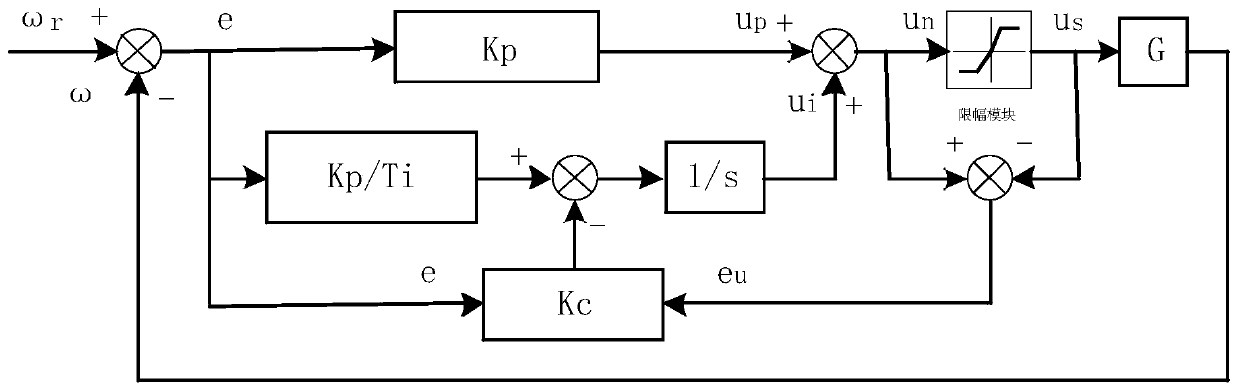

Method used

Image

Examples

Embodiment

[0037] Select a permanent magnet synchronous motor, rated power P=1kw, rated current In=5.3A, set the control variable of the PI controller ωr=3000 (rpm), the parameters of the PI controller Kp=160(rad / s), Ti= 0.02(s), output limit to PI controller, limit value Us=9.54(N·m).

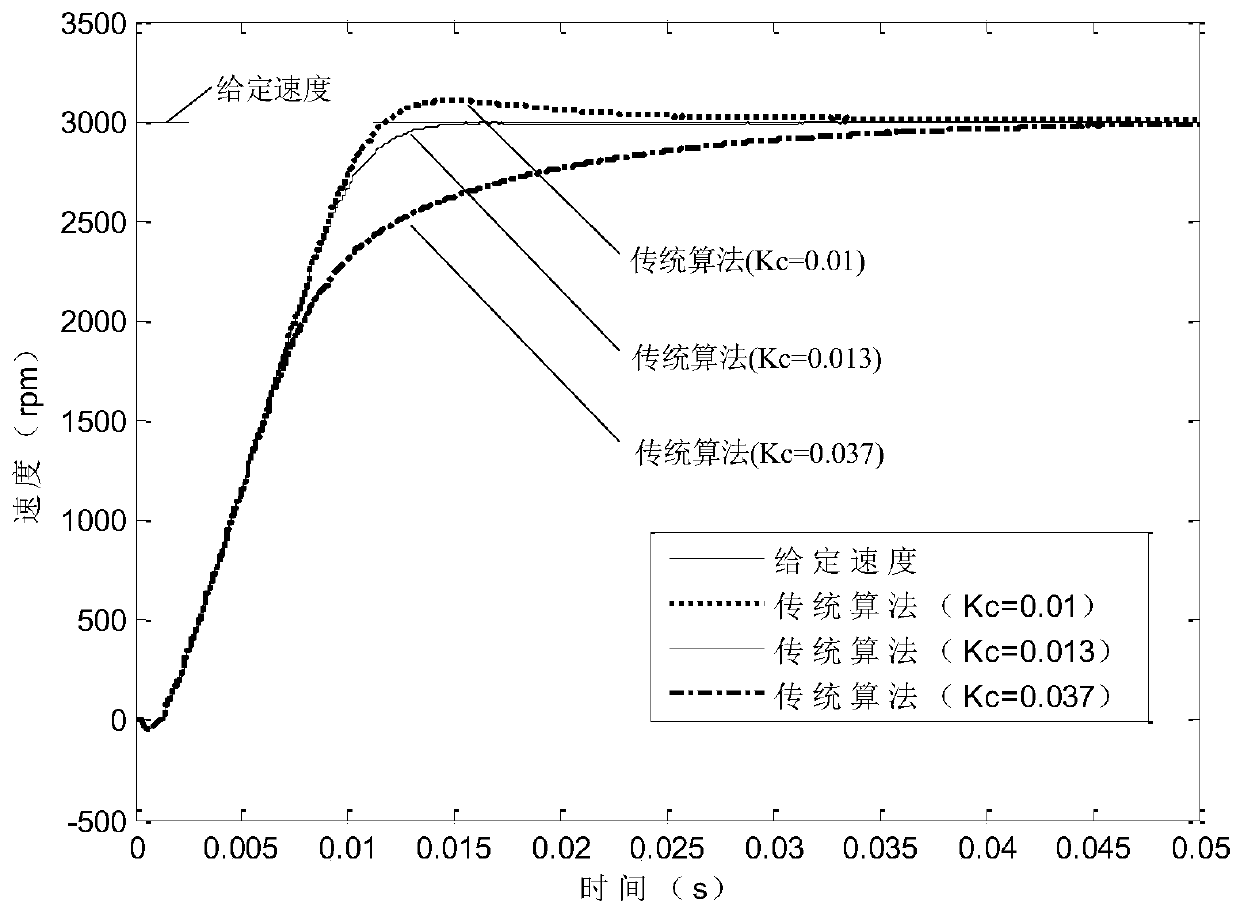

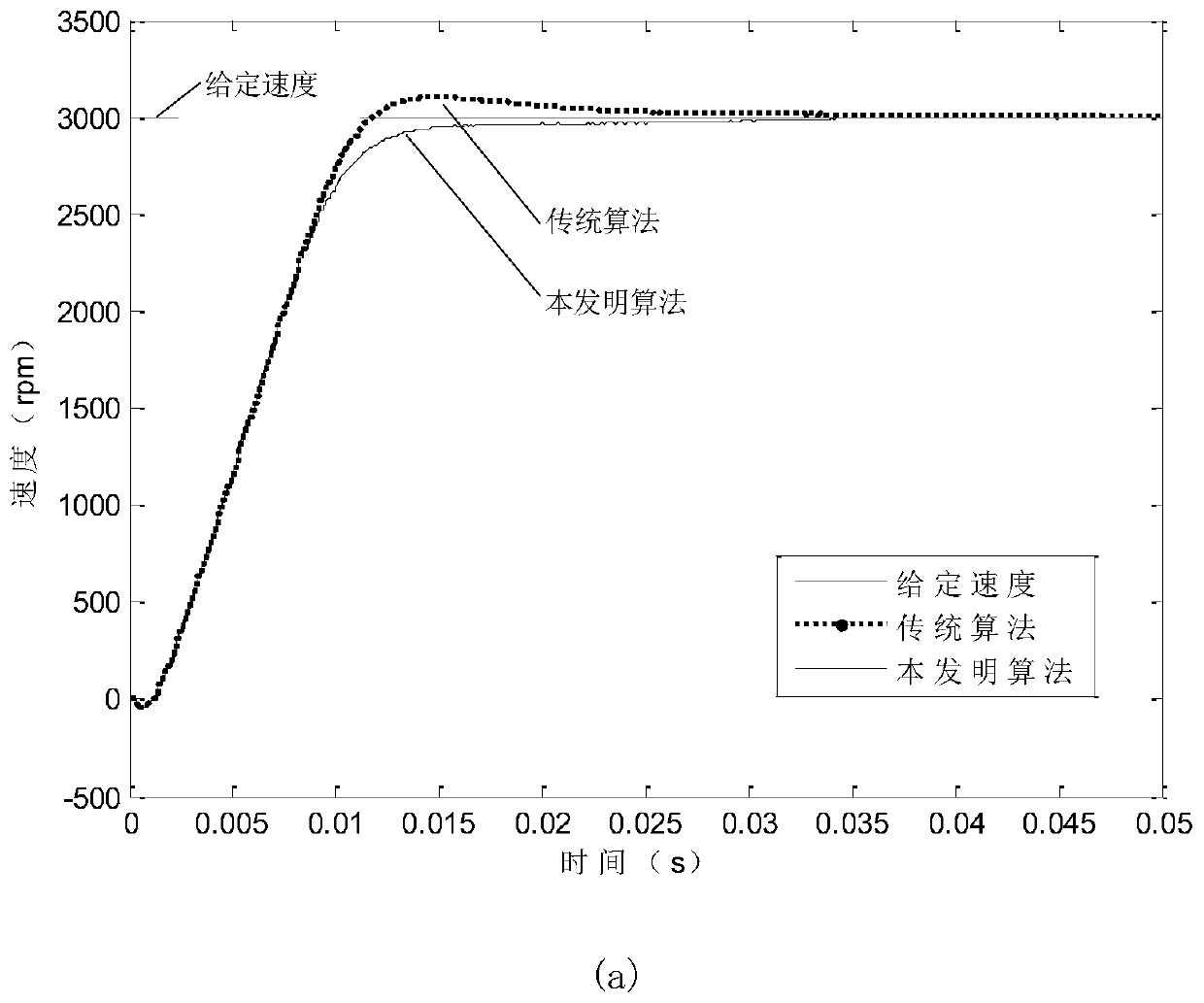

[0038] Simulation in Matlab, when there is no threshold constant α, when the compensation coefficient Kc is 0.01, 0.013, 0.037 respectively, the obtained feedback control quantity is as follows figure 2 .

[0039] Depend on figure 2 It can be seen that the compensation coefficient Kc has a great influence on the control effect. When Kc is set reasonably (Kc=0.013), the effect of saturation and desaturation is equivalent, the algorithm can eliminate overshoot well, and the system has the most ideal response; when the setting of Kc is small (Kc=0.01), the effect of desaturation is small, As a result, the system still has a certain overshoot; when Kc is set too large (Kc=0.037), the desaturation effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com