A Method for Preventing Cracking of Ceramic Model Shell

A ceramic mold and crack technology, applied in the direction of core, mold, mold composition, etc., can solve the problem that the dewaxing port cannot use the non-processing position, and achieve the effect of saving financial resources, easy implementation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

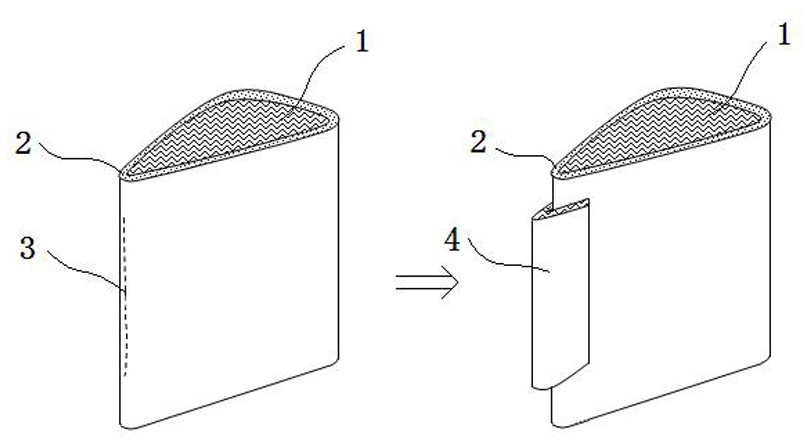

[0024] Such as figure 1 As shown, taking investment casting precision casting of gas turbine turbine blades as an example, the method for preventing cracking of the ceramic shell includes the following steps:

[0025] 1) A ceramic shell 2 with a certain thickness is manufactured by adopting the manufacturing process of the ceramic shell 2 .

[0026] The specific operation of this step is as follows:

[0027] a. After heating the medium-temperature wax material to 62°C with a wax press machine, inject the wax material into the metal mold of the turbine moving blade of the gas turbine under an injection pressure of 6 bar, and take out the wax material after cooling to obtain the wax mold 1 of the turbine moving blade;

[0028] b. Using the same process as step a to suppress the wax mold of the gating system;

[0029] c. Assemble the turbine moving blade wax mold 1 and the gating system wax mold with electric welding knife and other tools to make a wax tree;

[0030] d. Bond t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com