Combustion chamber of liquid-propellant rocket engine and inner wall thereof

A liquid rocket and combustion chamber technology, applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems such as the inability to popularize and apply the diffusion welding process, poor welding quality at both ends of the combustion chamber, and end cracks, etc. No obvious performance drop, good thermal fatigue performance and good welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

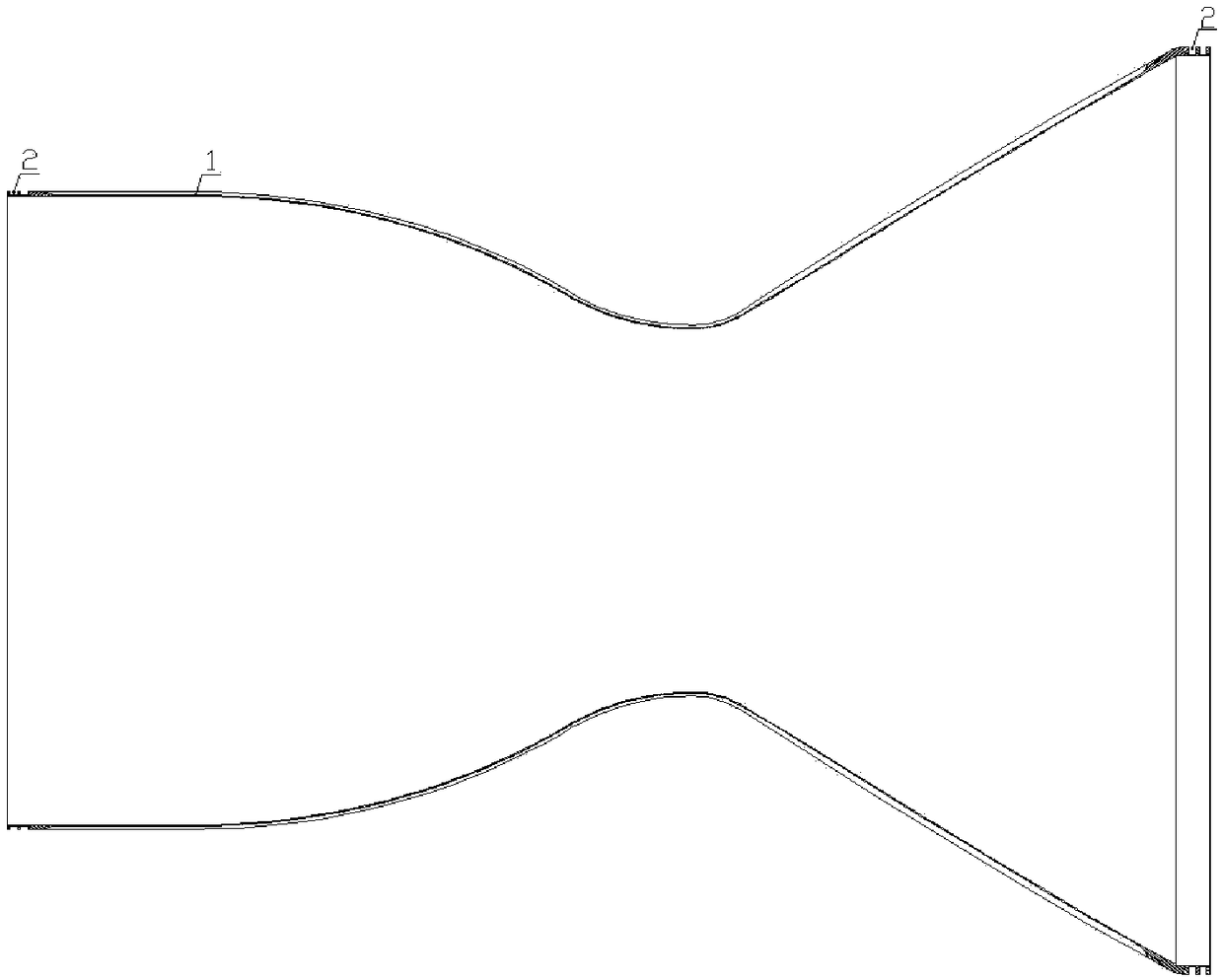

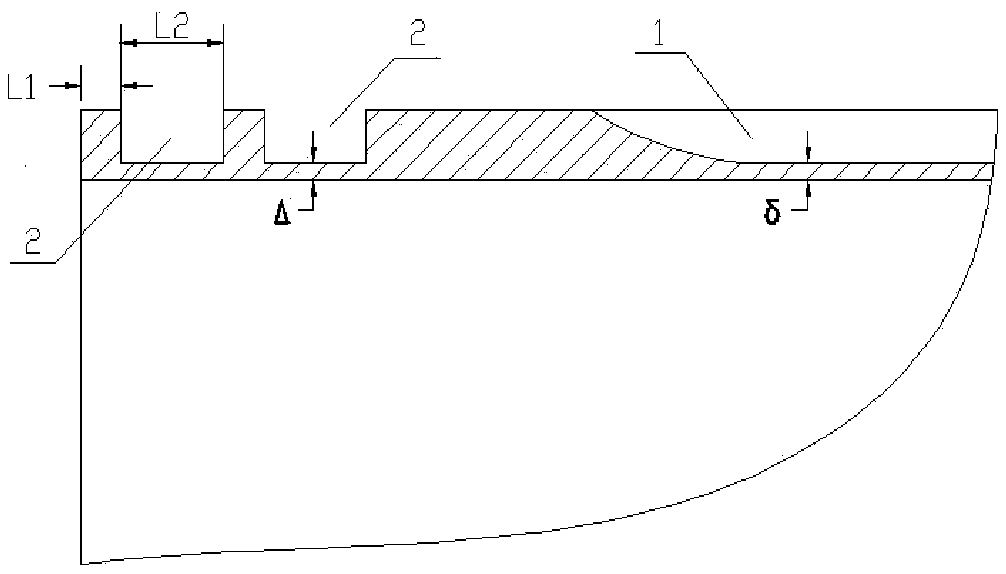

[0035] The combustion chamber wall of a liquid rocket engine is made of chrome-zirconium copper, and the outer surface of the combustion chamber wall is provided with a process ring groove 2 and a groove inner wall 1 . The combustion chamber adopts Laval surface structure.

[0036] The process ring groove 2 is located at both ends of the outer surface of the combustion chamber wall. In this embodiment, the number of process ring grooves 2 at each end is 2, and the cross section of the process ring groove 2 is rectangular, which is processed and formed by a milling machine; the groove The inner wall 1 is located in the middle of the outer surface of the inner wall of the combustion chamber, and the inner wall 1 of the groove is semi-oblong.

[0037] In this embodiment, the groove width L2 of each process ring groove 2 is 2.5L1, and L1 is the minimum distance between the end surface of the inner wall of the combustion chamber and the process ring groove 2 . In this embodiment, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com