Black tea processing technology

A processing technology and technology of black tea, which is applied in the field of tea production, can solve the problems of difficulty in mastering the degree of fermentation, insufficient leaf green damage, and high green content of tea leaves, and achieve the effects of easy mastery and popularization, shortened production time, and high-sweet aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

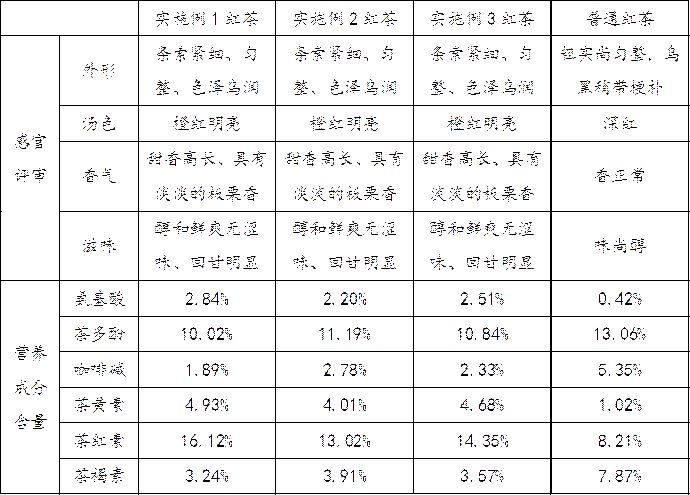

Embodiment 1

[0070] A black tea processing technology, which includes the following steps:

[0071] (1) Tea selection

[0072] Select fresh tea leaves that are collected on the same day without mechanical damage, insect eyes, and consistent tenderness, and select tea buds, one-bud and one-leaf tea and one-bud and two-leaf tea to obtain tea to be processed;

[0073] (2) Frozen

[0074] After unfolding the tea to be processed obtained in step (1), put it in a freezer with a model of BD-380B and a power of 735W and freeze it at a temperature of -18℃ until the water inside the tea to be processed is analyzed. Ice crystals are formed on the surface of the tea to make the tea hard and brittle to the extent that it can be crushed by hand, freezing for 12 hours to obtain frozen tea;

[0075] (3) Thawing stalls and drying

[0076] Spread the frozen tea leaves obtained in step (2) on the tea stand drying table. The tea stand is ventilated from bottom to top. The frozen tea leaves are thawed and dried at room ...

Embodiment 2

[0088] A black tea processing technology, which includes the following steps:

[0089] (1) Tea selection

[0090] Select fresh tea leaves that are collected on the same day without mechanical damage, insect eyes, and consistent tenderness, and select tea buds, one-bud and one-leaf tea and one-bud and two-leaf tea to obtain tea to be processed;

[0091] (2) Frozen

[0092] After unfolding the tea to be processed obtained in step (1), put it in a freezer with a model of BD-380B and a power of 735W and freeze it at a temperature of -30℃ until the water inside the tea to be processed is analyzed. Ice crystals are formed on the surface of the tea to make the tea hard and brittle and to the extent that it can be crushed by hand, freezing for 10 hours to obtain frozen tea;

[0093] (3) Thawing stalls and drying

[0094] Spread the frozen tea leaves obtained in step (2) on the tea stand drying table. The tea stand is ventilated from bottom to top. The frozen tea leaves are thawed and dried at r...

Embodiment 3

[0106] A black tea processing technology, which includes the following steps:

[0107] (1) Tea selection

[0108] Select fresh tea leaves that are collected on the same day without mechanical damage, insect eyes, and consistent tenderness, and select tea buds, one-bud and one-leaf tea and one-bud and two-leaf tea to obtain tea to be processed;

[0109] (2) Frozen

[0110] After spreading the tea to be processed obtained in step (1), put it in a freezer with model BD-380B and power of 735W and freeze it at a temperature of -5°C until the water inside the tea to be processed is analyzed. Ice crystals are formed on the surface of the tea to make the tea hard and brittle to the extent that it can be crushed by hand, freezing for 14 hours to obtain frozen tea;

[0111] (3) Thawing stalls and drying

[0112] Spread the frozen tea leaves obtained in step (2) on the tea stand drying table. The tea stand is ventilated from bottom to top. The frozen tea leaves are thawed and dried at room tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com