A treatment method for reducing the release of crotonaldehyde from shredded stems

A treatment method and release technology, applied in the field of tobacco processing, can solve the problems of cumbersome treatment process, reduction of crotonaldehyde release, popularization and application of difficult tobacco stem treatment process, etc., achieve simple treatment method, convenient operation, increase Maillard The effect of the reaction product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

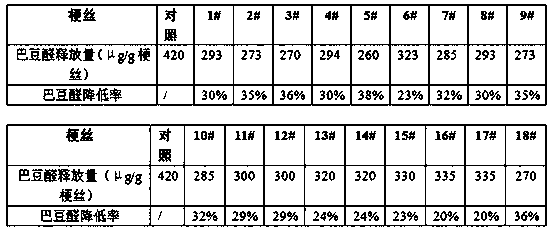

Examples

Embodiment 1~6

[0052] In order to evaluate the effect of reducing the release of crotonaldehyde in cut stems under different treatment methods, the inventors have carried out a series of experiments, and the specific cut stems treatment methods include the following treatment process:

[0053] (1) Fermentation treatment: Spray yeast aqueous solution, or yeast and biological enzyme aqueous solution evenly into the shredded stems, and then carry out fermentation treatment;

[0054] (2) Drying treatment. After drying the cut stems after the fermentation treatment in step (1), they can be used as finished cut stems for production and application; in the preferred treatment method, during the fermentation treatment of step (1), amino acids are also mixed with Saccharomyces cerevisiae, or Yeast and biological enzyme aqueous solution are added to the cut stem sample at the same time;

[0055] In the specific treatment, after the fermentation treatment in step (1), amino acids are evenly mixed into ...

Embodiment 1

[0058] In step (1), 0.25wt% Saccharomyces cerevisiae aqueous solution with dry weight of cut stems is sprayed. After spraying, the moisture content of cut stems is about 65%, fermented at 35°C for 16 hours, and then subjected to subsequent drying treatment.

Embodiment 2

[0060] The same as the fermentation treatment in Example 1, that is: in step (1), spray 0.25wt% Saccharomyces cerevisiae aqueous solution with the dry weight of cut stems, after spraying, the moisture content of cut stems is about 65%, and ferment at 35°C for 16 hours;

[0061] Then add proline powder with a dry weight of 2.0 wt% of the cut stems to the cut stems, mix evenly, and perform subsequent drying treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com