Noodle cooking barrel with injection pipe

A technology of ejector tubes and noodle barrels, which is applied in lighting and heating equipment, gas fuel burners, combustion methods, etc., can solve the problems of mixing, burner power limitation, endangering life, health and safety, etc., and achieve consistent power and full combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

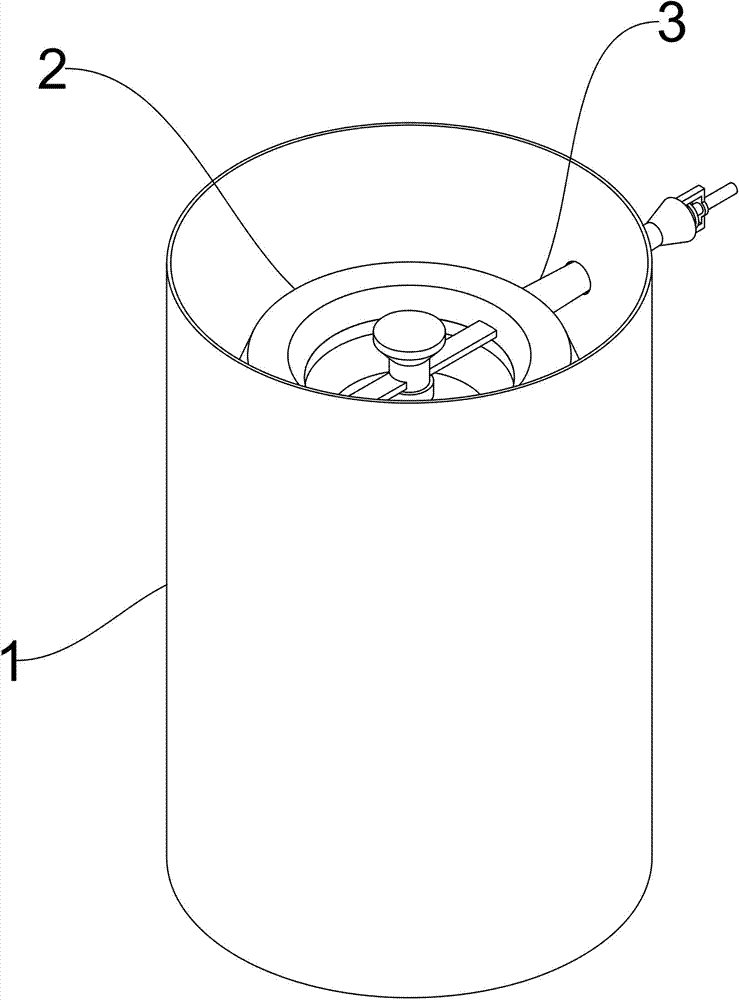

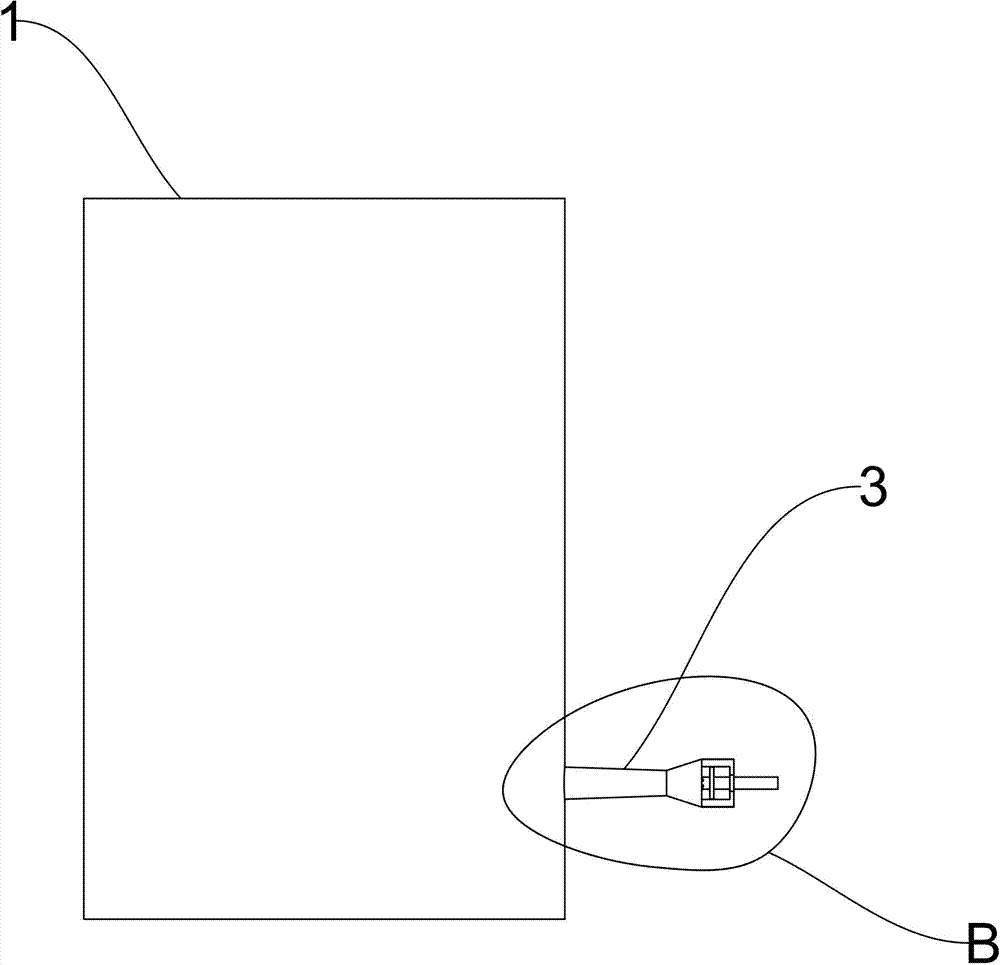

[0026] The advantage of the noodle cooking bucket with injection pipe of the present invention is that by adding an injection pipe outside the barrel body, when the high-pressure gas enters the connecting pipe, the air can also be injected into the connecting pipe, and the connection Both ends of the tube have a trumpet structure, the gas and air can be fully mixed and slowed down in the connecting tube, so that the mixed gas can evenly enter the multiple flame distributors on the burner, not only the gas burns fully, but also the burner The power of the multiple firearms on it is also relatively consistent.

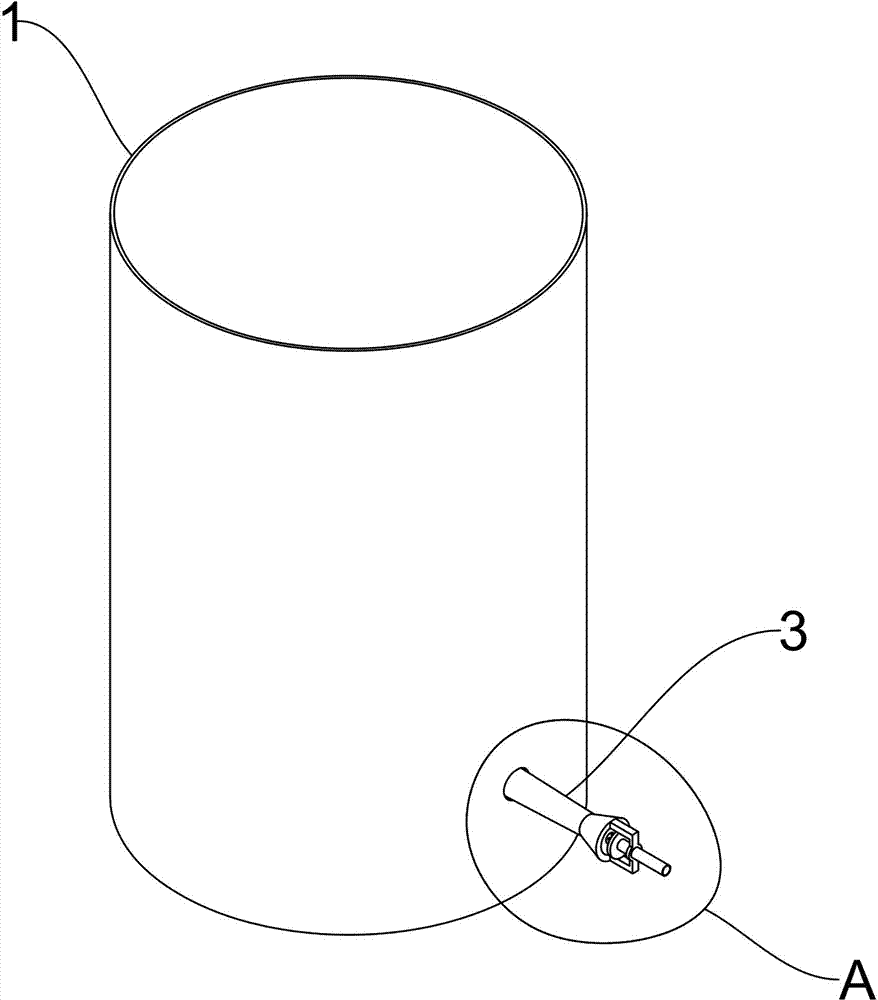

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown, a k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com