Automatic basket ball pitching machine and assembling method thereof

An assembly method and ball machine technology, applied in the direction of balls, sports accessories, etc., can solve the problem of lack of mature products, and achieve the effect of improving the technical level, improving the comprehensive technical level, and facilitating transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

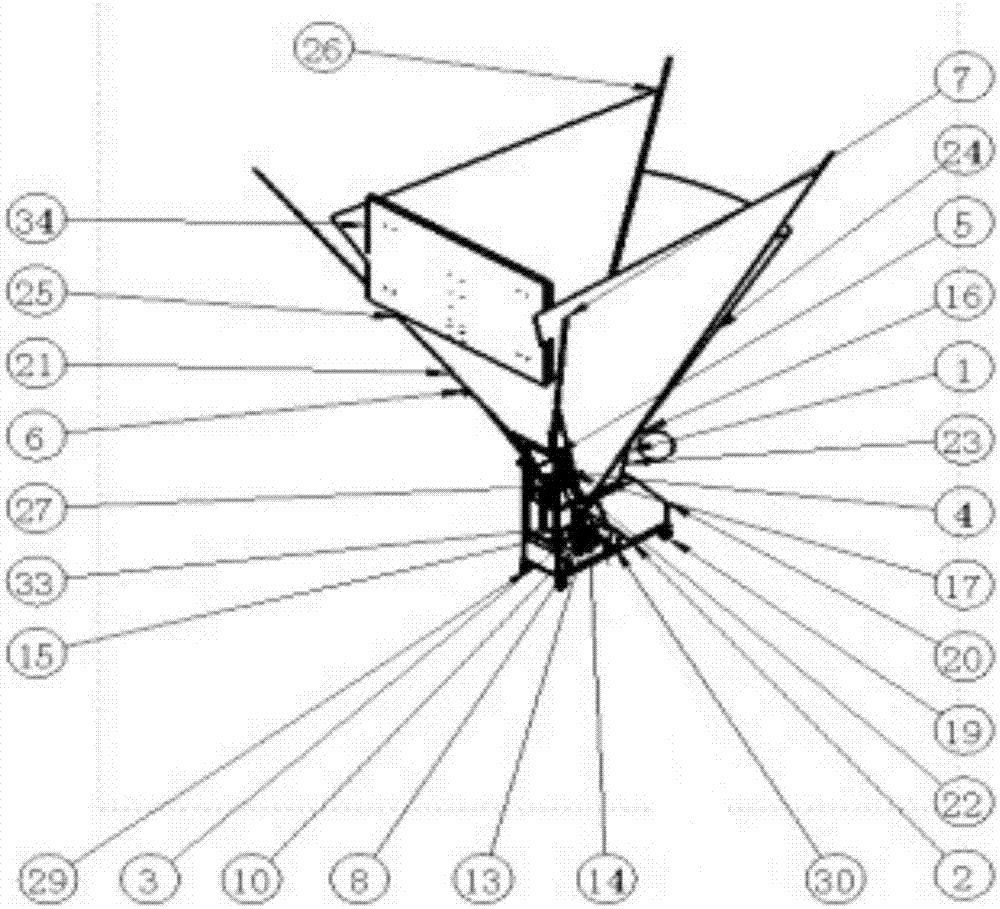

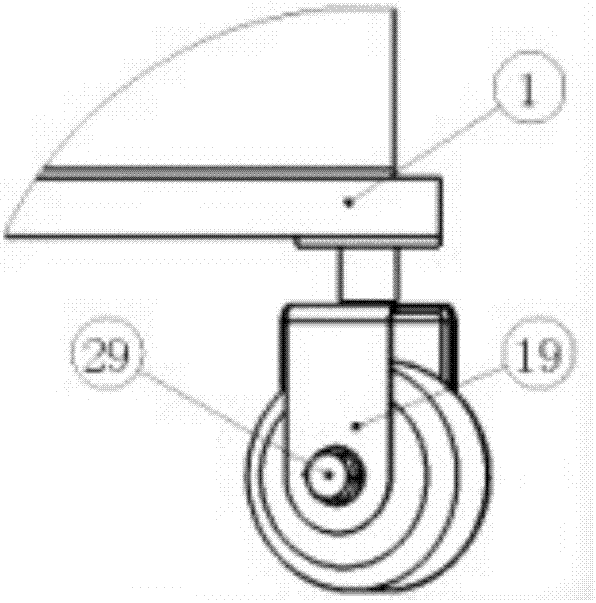

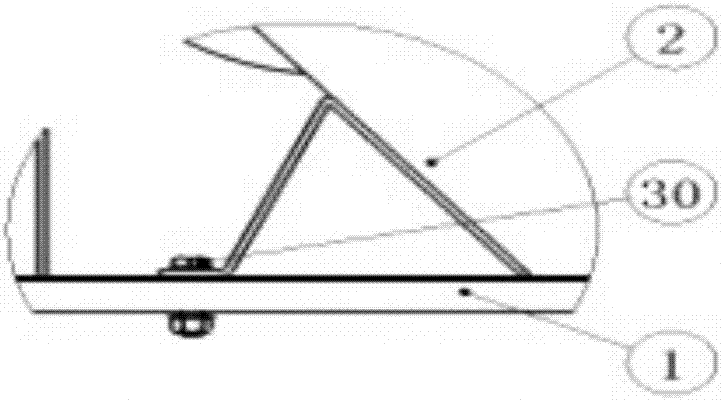

[0025] see figure 1, a basketball automatic ball machine, comprising a ball machine body 1, a ball machine housing 2, a front right bracket 3, a front left bracket 4, a rear right bracket 5, a rear left bracket 6, a movable rod 7, an upper cover plate 8, Lower cover plate 9, micro-cylinder fixing plate 10, automatic ball-serving device, data monitoring device, display and control panel assembly 20, housing inner net 22, upper and lower ring nets 23, front net 24, rear net 25, side nets 26. A standard backboard 34 and a standard hoop 35; the bottom of the ball machine body 1 is provided with universal wheels 19, the ball machine housing 2 is arranged on the ball machine body 1, and the miniature cylinder fixing plate 10 is connected with the ball machine body 1. The locomotive body 1 is connected, and the automatic ball-serving device includes a motor-driven miniature air compressor 12 and a miniature cylinder block 13, which are connected by a compressor cylinder connection ru...

Embodiment 2

[0029] see Figure 2-8 , the assembly method of this basketball automatic ball machine, comprises the following steps: a. the universal wheel 19 is arranged on the bottom of the ball machine body 1, and is firmly connected with it; b. adjusts the position of the ball machine housing 2, and The ball machine housing 2 is arranged on the ball machine body 1 and is firmly connected; c. the miniature cylinder fixed plate 10 is connected with the ball machine body 1, and the motor drives the micro air compressor 12 and the miniature air cylinder body 13 Connect the rubber tube 11 by the compressor cylinder, connect the miniature cylinder movable rod 14 in the miniature cylinder cylinder block 13, and connect the serving push pad 15 at its front end, the miniature cylinder cylinder block 13 is connected firmly with the miniature cylinder fixed plate 10, and Described motor drives miniature air compressor 12 and is arranged on described ball locomotive car body 1, and is arranged betw...

Embodiment 3

[0035] As a further improvement, in addition to having the above-mentioned technical features, the compressor cylinder connecting rubber tube 11 is made of aging-resistant rubber material, and its raw materials include by weight: 45-50 parts of polystyrene butadiene copolymer, 12-15 parts of copolymer of isobutylene and isoprene, 25-30 parts of chloroprene rubber, 1.5-2.5 parts of silane coupling agent, 1.5-3 parts of LH-C96 curing agent, 0.5-1.5 parts of accelerator CZ 2-3 parts of bakelite powder, 2-4 parts of antioxidant 4010NA. The rubber material supported by the above raw materials can significantly improve the aging resistance of the rubber.

[0036] The connection between the compressor cylinder connecting rubber tube 11 and the motor-driven miniature air compressor 12 and the miniature cylinder body 13 has a pipe liner respectively, and the tube liner is fixedly connected to the end of the compressor cylinder connecting rubber tube 11 , and the outer circumferential ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap