A flue gas pollutant spraying-absorbing column inner member capable of adjusting a local fluidized wind speed

A spray absorption tower, fluidized wind speed technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems that are difficult to adapt to frequent load changes of units, operators cannot actively adjust boilers, and difficult local mass transfer flow to meet the requirements of pollutant discharge, superior gas-liquid mass transfer effect, and the effect of strengthening the gas-liquid mass transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

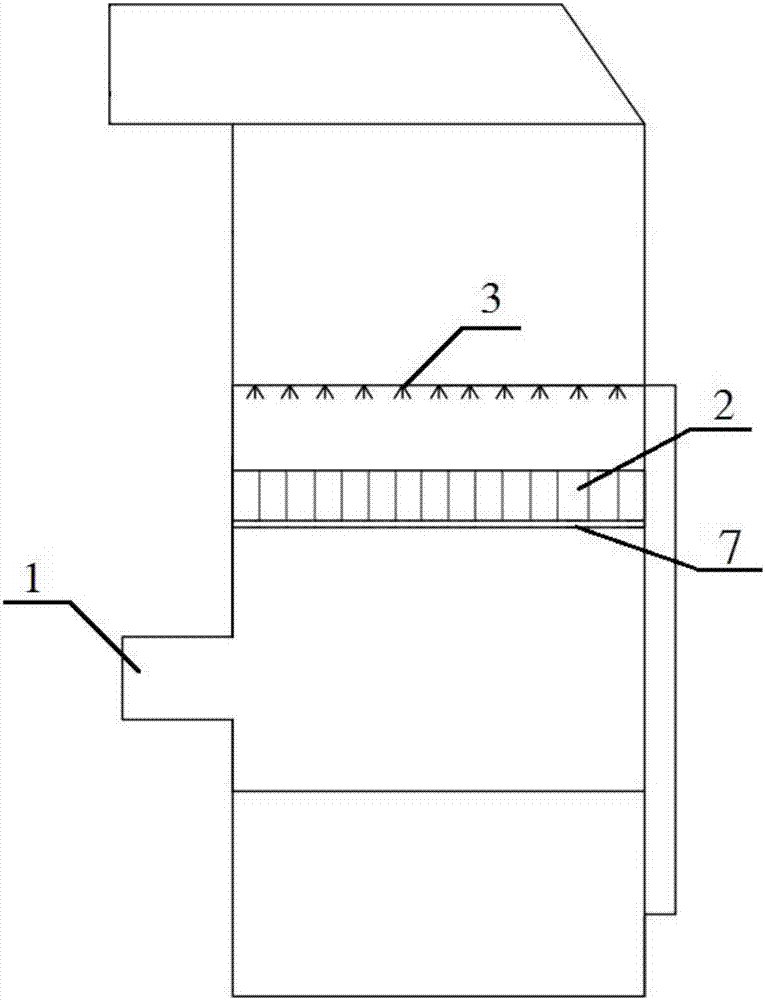

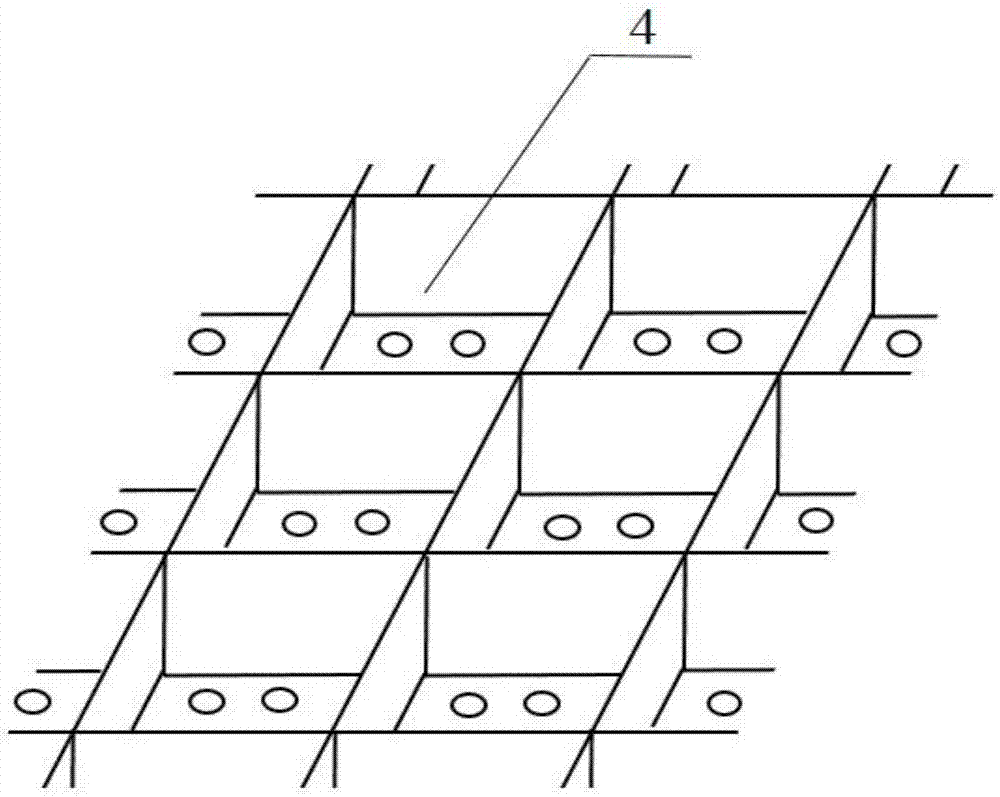

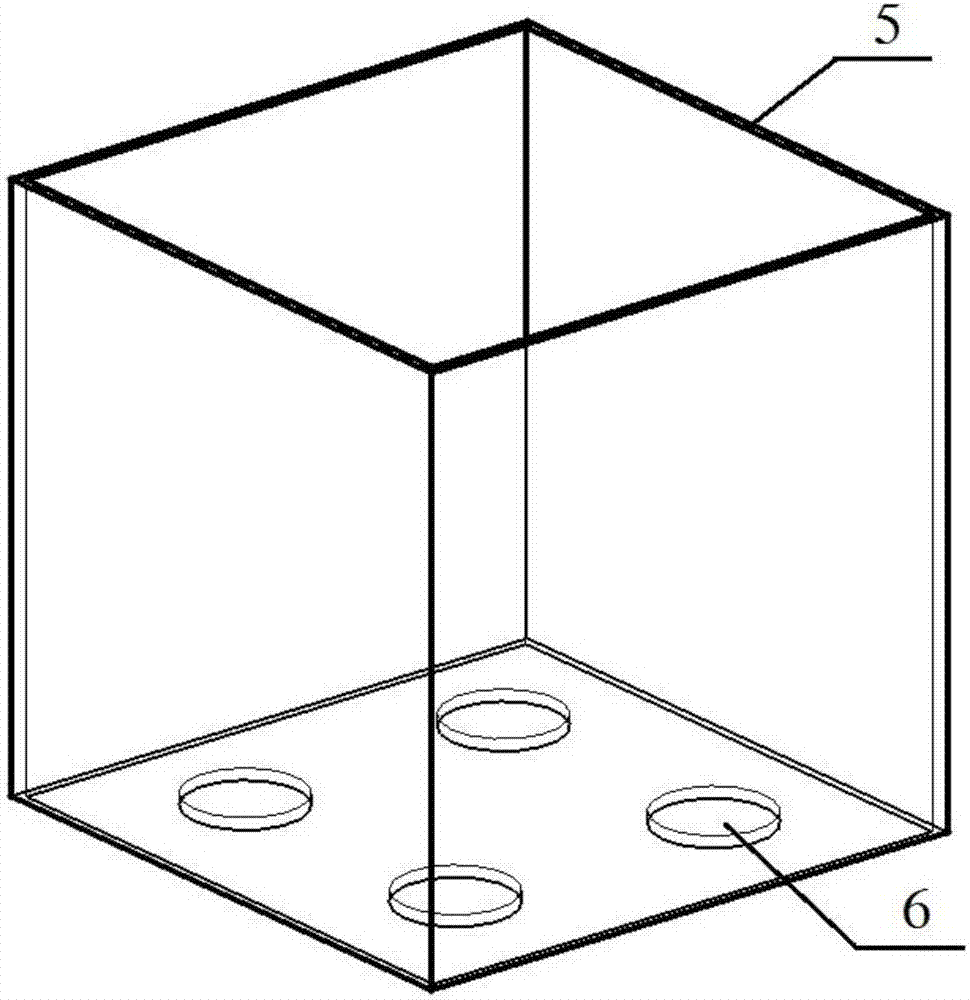

[0022] The specific structure of the present invention will be further described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention and not to limit the scope of the present invention.

[0023] The present invention provides a flue gas pollutant spray absorption tower internal component capable of adjusting the local fluidization wind speed, the component includes a fluidization unit group 2, a fluidization wind speed adjustment plate 7 and an adjustment plate control device 9; fluidization unit Group 2 is composed of multiple local fluidization units 4, which are installed under the spray layer 3 of the spray absorption tower, covering the entire horizontal section of the spray absorption tower. The fluidizing wind speed adjusting plate 7 is horizontally installed under the fluidizing unit group 2, and the vertical gap between the fluidizing wind speed adjusting plate 7 and the fluidizing unit group 2 is 0-30 mm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com