A kind of stone mill production process of wheat aleurone layer flour

A technology of wheat aleurone layer and production process, which is applied in the field of stone mill production process of wheat aleurone layer powder, can solve the problems of low purity, nutrient destruction, high cost, etc., and achieve obvious separation effect, less nutrient destruction, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

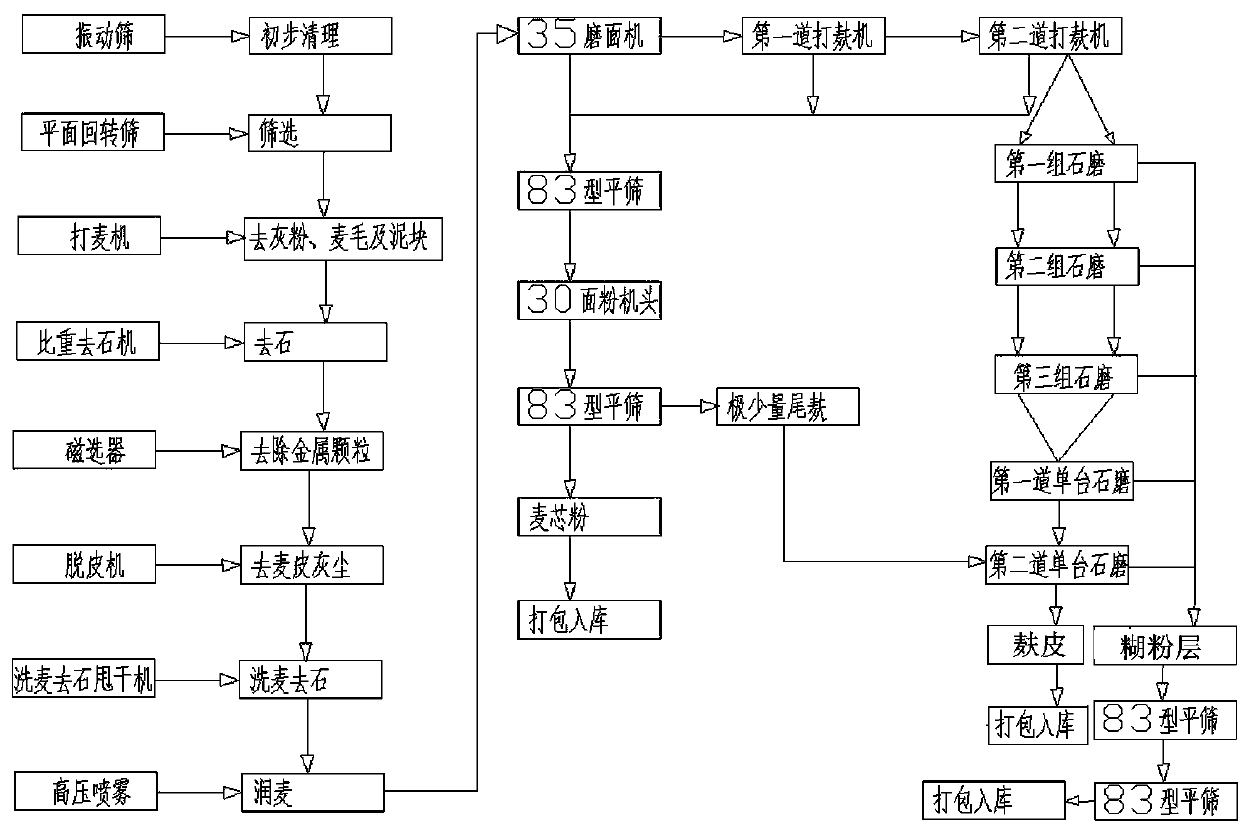

[0015] The structure of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0016] See attached figure 1 , a stone mill production process of wheat aleurone layer flour, which is completed through the following steps: 1) Wheat cleaning: After the wheat is initially cleaned through a vibrating sieve, the following treatments are carried out in sequence: screening through a flat rotary sieve, passing through a thresher Remove ash powder, wheat hair and mud, use a specific gravity stoner to remove stones, remove metal particles through a magnetic separator, remove wheat husk dust through a peeling machine, and then use a wheat washing and stone removal machine to wash and remove stones ;2) Tempering treatment: the wheat obtained in step 1) should be flexibly controlled according to the quality and moisture content, the moisture content should be controlled at 15%-17%, and the tempering time is 18-24 hours. 3) Flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com