Double-laser-beam composite welding method

A hybrid welding and laser beam technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of focus fluctuation and difficult control of beam centering, etc., to reduce sensitivity, eliminate non-fusion, and increase adaptability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The workpiece to be welded is a 304 stainless steel plate with a thickness of 8mm, and the plate butt joint method is adopted.

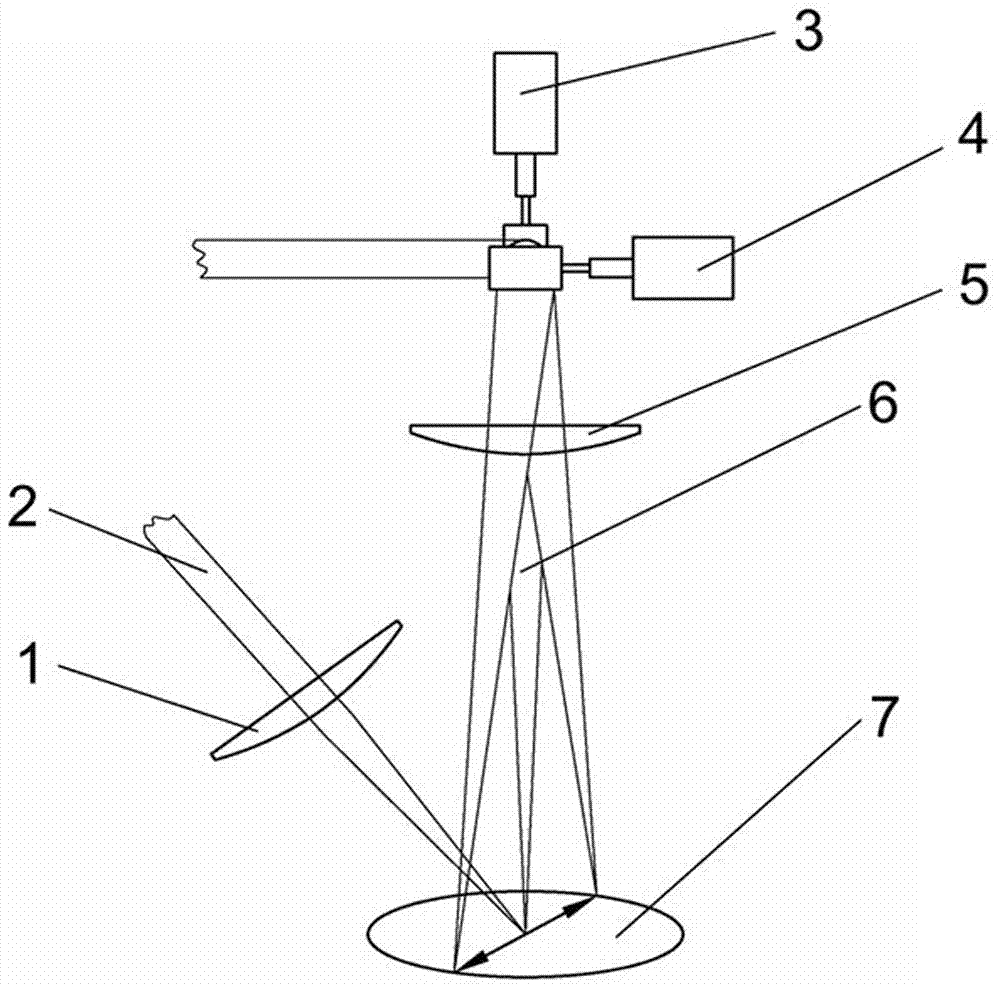

[0026] Fix the workpiece to be welded on the workbench, and at the same time fix the welding head composed of scanning galvanometer, collimating focusing lens, etc. on the manipulator, and adjust the distance between the scanning galvanometer and the surface of the weld.

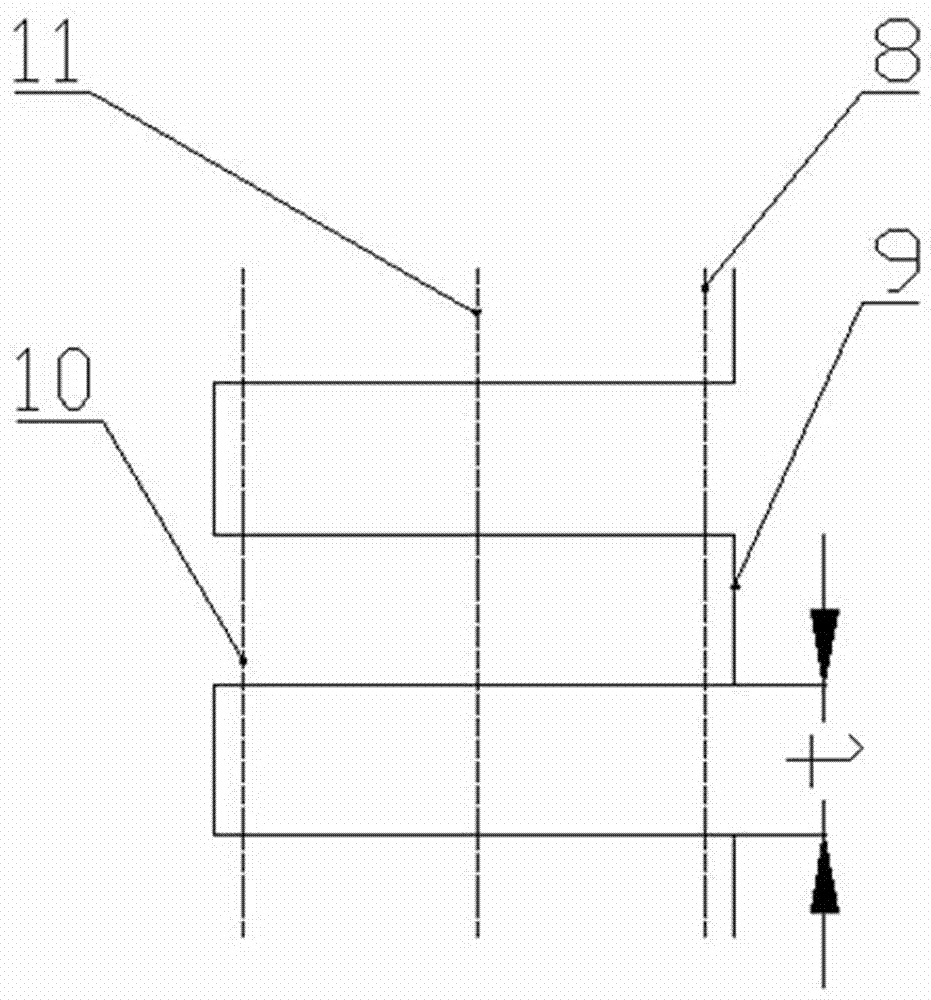

[0027] Welding is carried out after the workpiece to be welded and the welding system are prepared. Set the laser power of the welding beam to 6000W, the defocus amount to -3mm, the laser power of the scanning beam to 3000W, the scanning speed of the galvanometer to 100mm / s, and the scanning method to use figure 2 In the form, the scanning distance is 0.4mm. The welding speed is 30mm / s. Protected by high-purity argon, the flow rate is 30L / min.

[0028] After the welding is completed, the test piece is inspected, the bottom of the joint is penetrated, the two sides are pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com