Automated industrial robot assembly

A technology of industrial robots and components, applied in the direction of conveyor objects, manipulators, manufacturing tools, etc., can solve the problems of loading and unloading misalignment, poor stability and reliability, and low efficiency, and achieve the effect of improving positioning and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

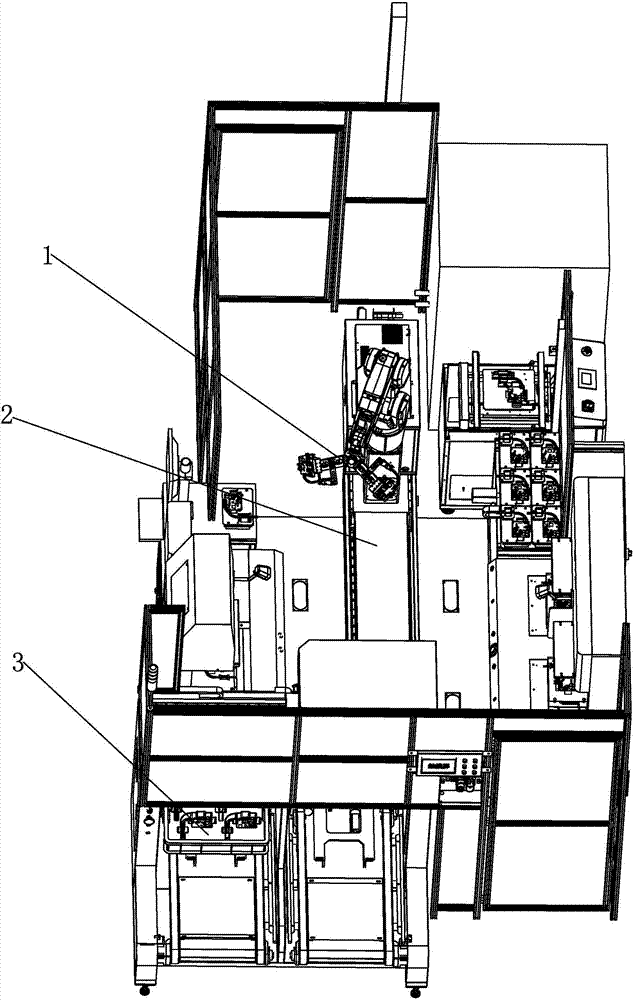

[0037] According to attached figure 1 As shown, the automatic industrial robot assembly of the present utility model includes an automatic manipulator, a control system, an automatic pick-up device 1, a conveying device 2 and an automatic loading and unloading device 3 for a turnover box, and the control system controls the automatic manipulator, the automatic pick-up device 1, and the conveying device 2 and turnover box automatic loading and unloading device 3.

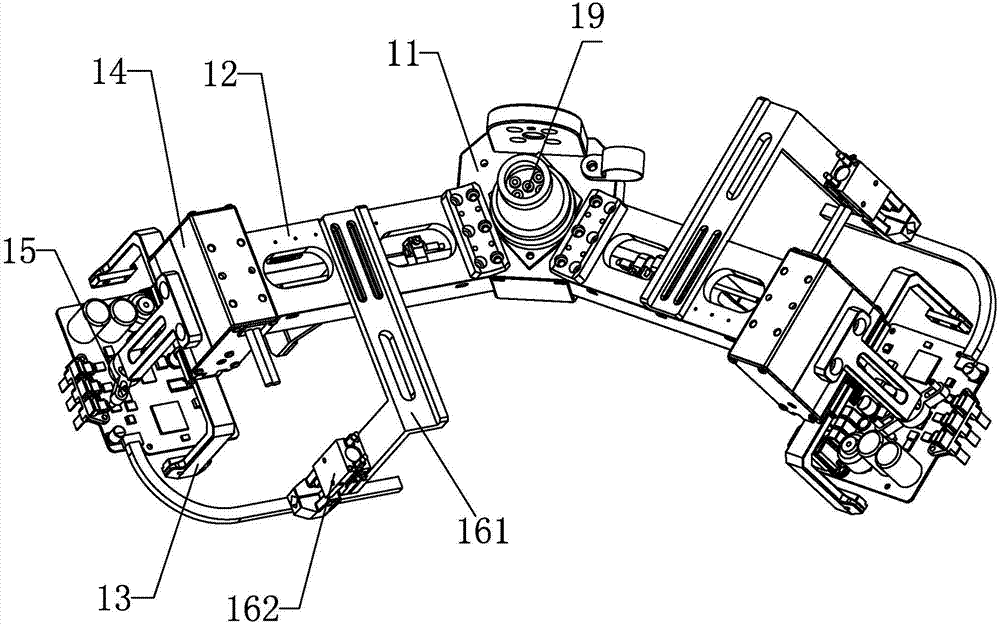

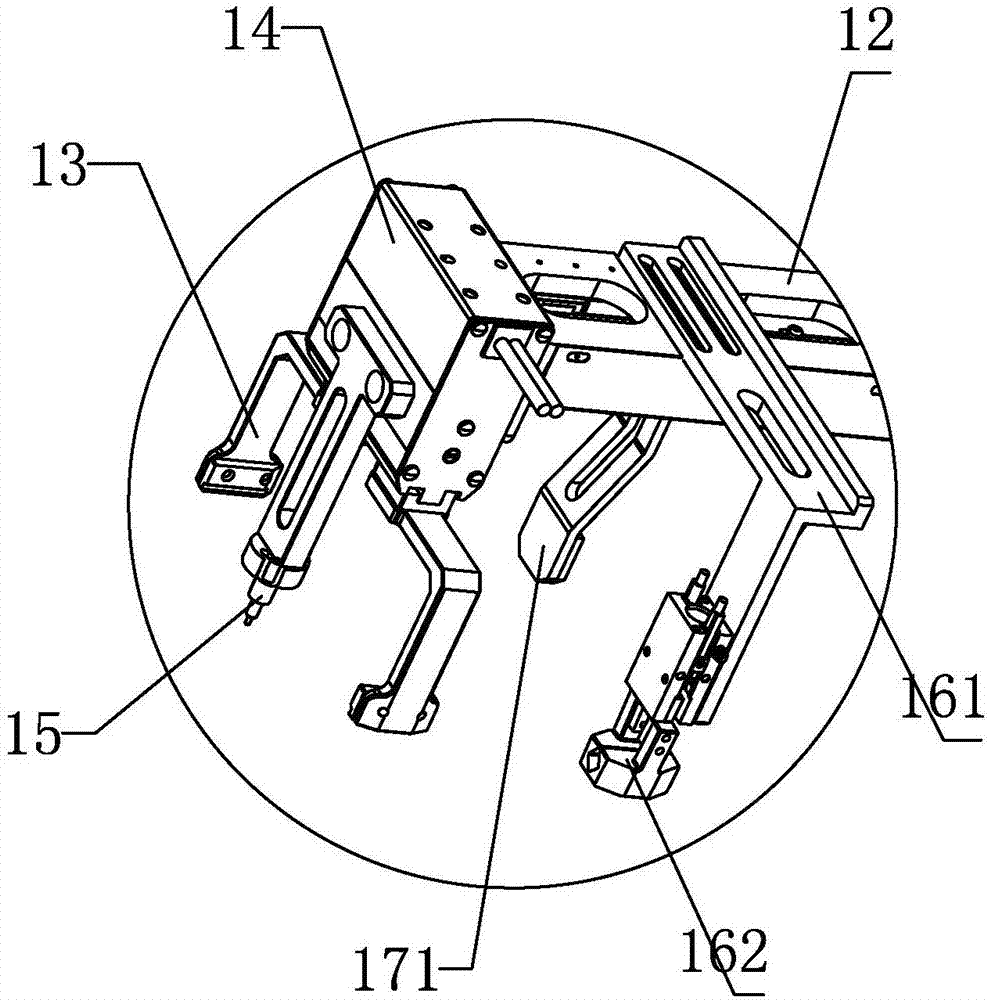

[0038] According to attached figure 2 , attached image 3 , attached Figure 4 As shown, the automatic picking device 1 of the automatic industrial robot assembly of the present invention mainly includes a first base 11 , a connecting base 12 , gripper jaws 13 and a servo driver 14 . Wherein, the connection base 12 is arranged on the first machine base 11 and is fixedly connected with the first machine b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap