Asphaltene dispersant for high pourpoint heavy oil

A technology of asphaltene dispersant and high-condensation heavy oil, which is applied in gas/liquid distribution and storage, drilling composition, pipeline system, etc., to achieve significant economic benefits, good temperature resistance, and prevent deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Highly poured viscous oil asphaltene dispersant G 1 and its preparation method

[0032] (1) Asphaltene Dispersant G for High Pouring Viscous Oil 1 The composition, components and molecular formula are as follows:

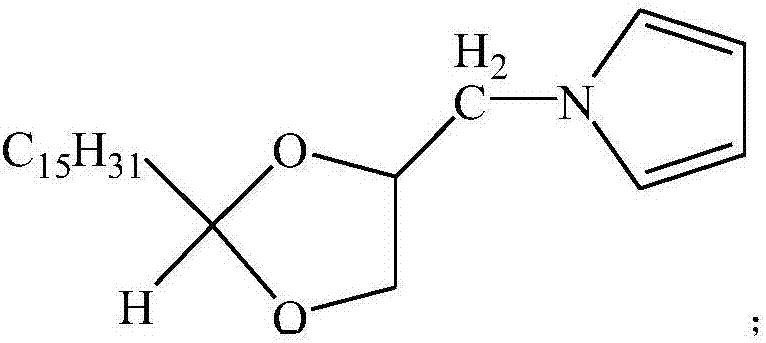

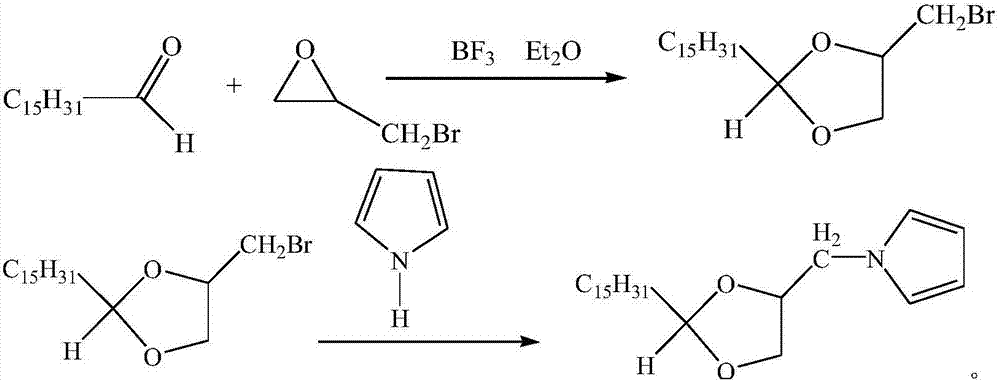

[0033] Asphaltene Dispersant G 1 The intermediate is first reacted with decanal and epibromohydrin, and then pyrrole is reacted with the intermediate to generate the final product. The molecular formula of the high-condensing asphaltene dispersant is as follows:

[0034]

[0035] The molar ratio of decanal, epibromohydrin and pyrrole is 1:1:1.

[0036] (2) Asphaltene Dispersant G for High Pouring Viscous Oil 1 The preparation method is as follows:

[0037] ①In a four-necked flask equipped with an electromagnetic stirrer, a reflux condenser and a thermometer, add 0.1mol of decanal, 31.2g of carbon tetrachloride and 1.56g of BF 3 ·Et 2 O solution was heated while stirring, the stirring rate was 220rpm, the stirring time was 10min, and the he...

Embodiment 2

[0042] Example 2 Highly poured viscous oil asphaltene dispersant G 2 and its preparation method

[0043] (1) Asphaltene Dispersant G for High Pouring Viscous Oil 2 The composition, components and molecular formula are as follows:

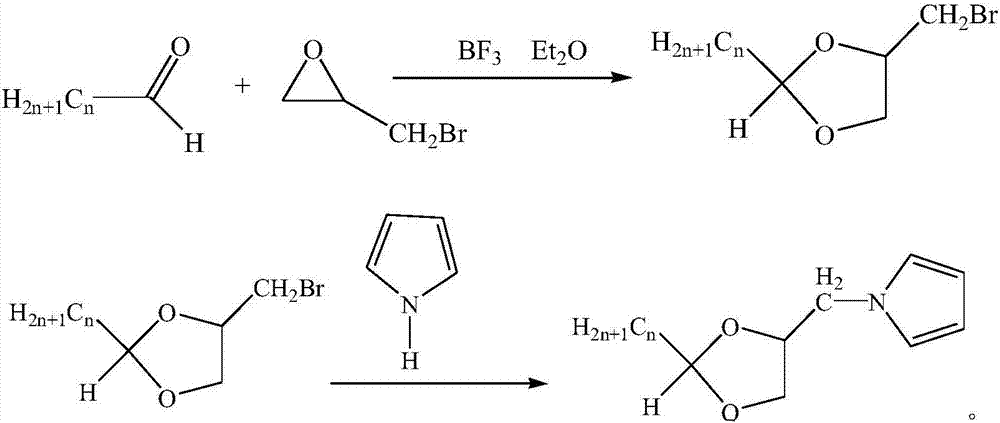

[0044] Asphaltene Dispersant G 2 The reaction between dodecanal and epibromohydrin first generates an intermediate, and then reacts pyrrole with the intermediate to generate the final product. The molecular formula of the high-condensing thick oil asphaltene dispersant is as follows:

[0045]

[0046] The molar ratio of dodecanal, epibromohydrin and pyrrole is 1:1.2:1.1.

[0047] (2) Asphaltene Dispersant G for High Pouring Viscous Oil 2 The preparation method is as follows:

[0048] ①In a four-necked flask equipped with an electromagnetic stirrer, a reflux condenser and a thermometer, add 0.1mol of dodecanal, 55.2g of carbon tetrachloride and 3.68g of BF 3 ·Et 2 O solution was heated while stirring, the stirring rate was 260rpm, the stirrin...

Embodiment 3

[0053] Example 3 Highly poured viscous oil asphaltene dispersant G 3 and its preparation method

[0054] (1) Asphaltene Dispersant G for High Pouring Viscous Oil 3 The composition, components and molecular formula are as follows:

[0055] Asphaltene Dispersant G 3 The intermediate is first reacted with tetradecaldehyde and epibromohydrin, and then pyrrole is reacted with the intermediate to generate the final product. The molecular formula of the high-condensing thick oil asphaltene dispersant is as follows:

[0056]

[0057] The molar ratio of tetradecaldehyde, epibromohydrin and pyrrole is 1:1.3:1.2.

[0058] (2) Asphaltene Dispersant G for High Pouring Viscous Oil 3 preparation method

[0059] ①In a four-necked flask equipped with an electromagnetic stirrer, a reflux condenser and a thermometer, add 0.1mol of tetradecanal, 53.0g of acetonitrile and 6.36g of BF 3 ·Et 2 O solution was heated while stirring, the stirring rate was 200rpm, the stirring time was 15min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Freezing point | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com