Benzocyclobutene polycarbosilane polymerized monomer or resin and preparation method thereof

A technology of benzocyclobutene polycarbosilane and benzocyclobutenyl disilacyclobutane, which is applied in the field of polymer compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

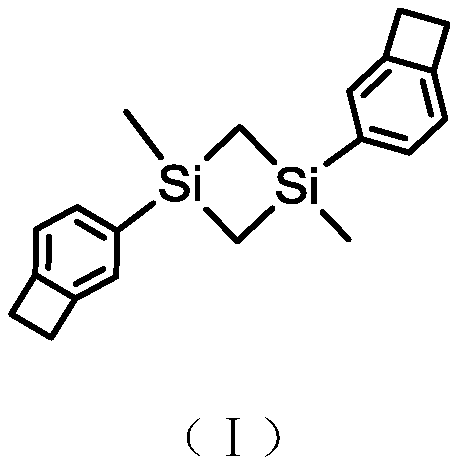

[0054] 1,3-dimethyl-1,3-dibenzocyclobutenyl disilacyclobutane, the benzocyclobutene polycarbosilane polymerization monomer has the chemical structural formula shown in formula (I):

[0055]

Embodiment 2

[0057] The preparation method of 1,3-dimethyl-1,3-dibenzocyclobutenyl disilacyclobutane, the steps are:

[0058] a. Synthesis of chloromethylmethylisopropoxychlorosilane:

[0059] In an ice-water bath, add 22.89 g of chloromethylmethyldichlorosilane to the reactor under the protection of nitrogen; take 7.8 g of isopropanol and add it to a constant pressure dropping funnel, and drop it into the reactor for 2 hours (slowly); After the addition is complete, continue the reaction at room temperature for 1 hour; throughout the reaction process, nitrogen gas has been passed to take away the hydrogen chloride gas generated in the reaction process; It is the distillate under the condition of 0.4~0.5 Torr, and the colorless transparent liquid is obtained, which is the obtained chloromethylmethylisopropoxychlorosilane;

[0060] b. Synthesis of 1,3-diisopropoxy-1,3-dimethyl-1,3-disilacyclobutane:

[0061] Add 1.64g of magnesium and 0.011g of iodine into the reactor, vacuumize and fill ...

Embodiment 3

[0066] The preparation method of 1,3-dimethyl-1,3-dibenzocyclobutenyl disilacyclobutane, the steps are:

[0067] a. Synthesis of chloromethylmethylisopropoxychlorosilane:

[0068] In an ice-water bath, add 22.89 g of chloromethylmethyldichlorosilane to the reactor under the protection of nitrogen; take 7.8 g of isopropanol and add it to a constant pressure dropping funnel, and drop it into the reactor over 4 hours (slowly); After the addition is complete, continue the reaction at room temperature for 1 hour; throughout the reaction process, nitrogen gas has been passed to take away the hydrogen chloride gas generated in the reaction process; It is the distillate under the condition of 0.4~0.5 Torr, and the colorless transparent liquid is obtained, which is the obtained chloromethylmethylisopropoxychlorosilane;

[0069] b. Synthesis of 1,3-diisopropoxy-1,3-dimethyl-1,3-disilacyclobutane:

[0070] Add 2.78g of magnesium and 0.013g of iodine into the reactor, vacuumize and fill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com