Non-pneumatic rubber inner tire

A rubber inner tube, air-free technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of small elasticity, poor riding comfort, and lack of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

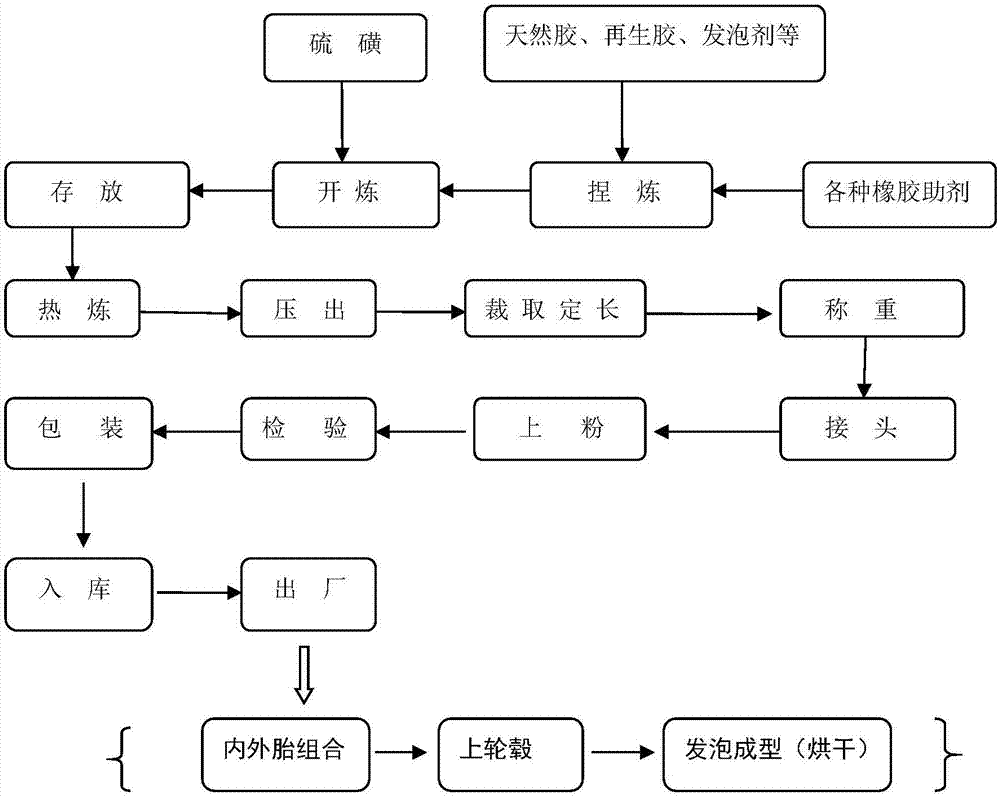

Method used

Image

Examples

Embodiment 1

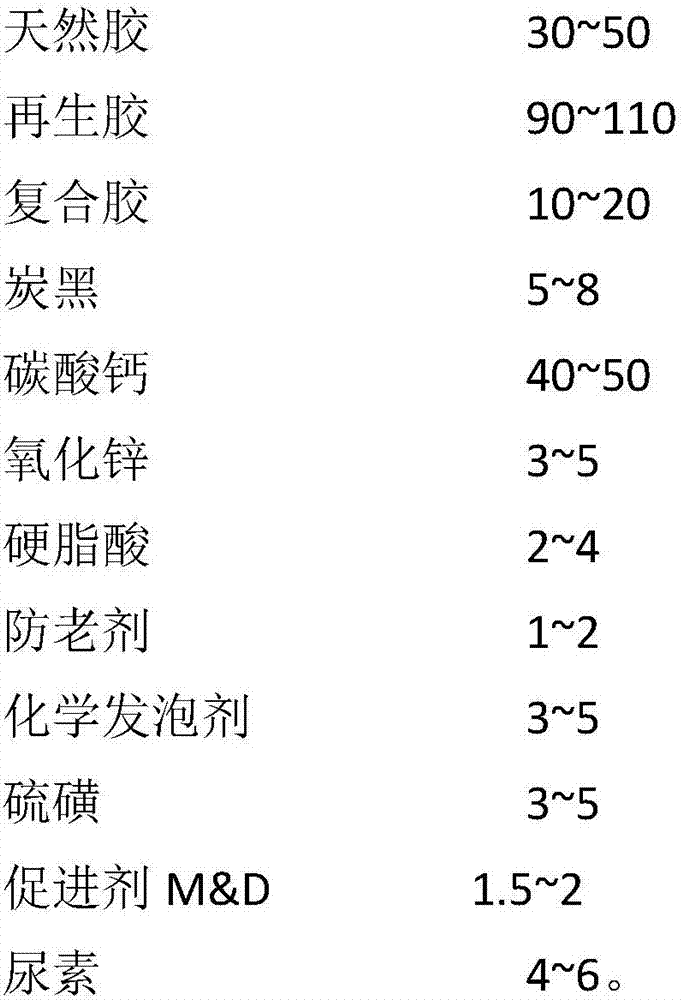

[0032] An air-free rubber inner tube is characterized in that the ratio of raw and auxiliary materials by weight includes the following components:

[0033]

[0034] Among the above materials,

[0035] Natural rubber: the tensile strength is required to be greater than 18 MPa.

[0036] Reclaimed rubber: It is required to be tasteless and fine reclaimed rubber above 60 mesh.

[0037] Composite glue: mainly to increase product elasticity.

[0038] Carbon black: more than N330 is required, mainly for reinforcement, increasing the wear resistance and hardness of the product.

[0039] Calcium carbonate: Fills the rubber body.

[0040] Zinc oxide: Activate the entire vulcanization system of rubber and increase the crosslink density.

[0041] Stearic acid: Activator, plasticizer and softener for rubber vulcanization.

[0042] Anti-aging agent: improve the aging resistance and thermal stability of the product.

[0043] Chemical foaming agent: closed-cell foaming is required, ...

Embodiment 2

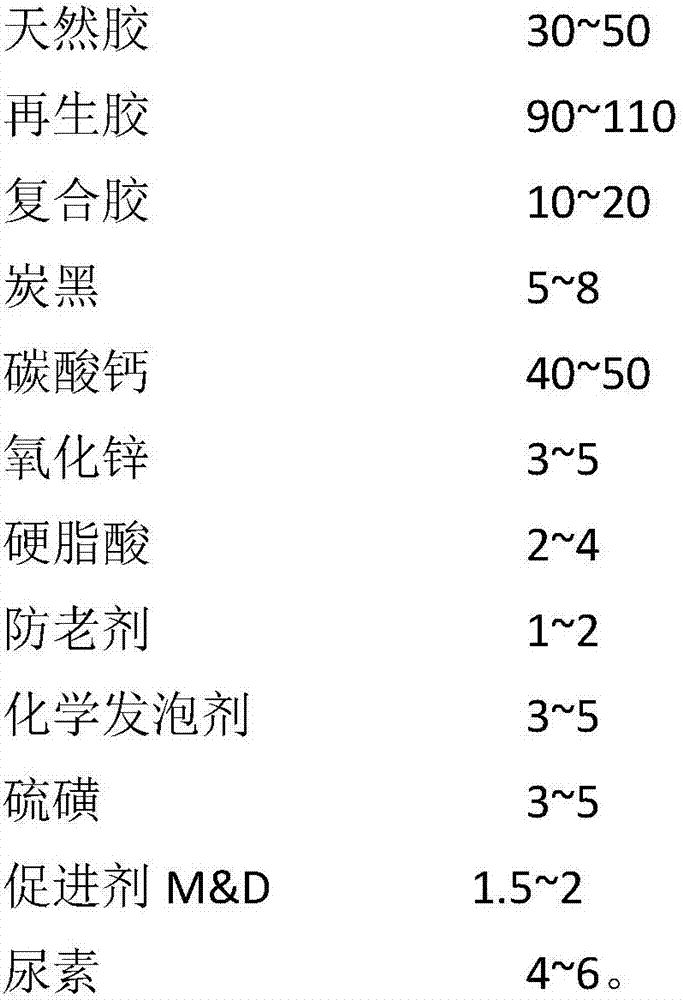

[0053] An air-free rubber inner tube is characterized in that the ratio of raw and auxiliary materials by weight includes the following components:

[0054]

[0055]

[0056] The manufacture method of above-mentioned air-free rubber inner tube, technological process are the same as embodiment 1

[0057] The inner tubes of rubber bicycles and baby carriages produced by the invention are of solid structure, sponge-like and porous after foam molding, free of inflation, puncture-resistant, highly elastic, and never "puncture".

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com