Rotating platform for testing unfolding of missile wing under multi-angle high-speed rotating condition of missile body

A high-speed rotation, multi-angle technology, applied in the direction of ammunition testing, ammunition, weapon accessories, etc., can solve the problems of single, large equipment, etc., to achieve the effect of simplifying the overall structure, convenient monitoring, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

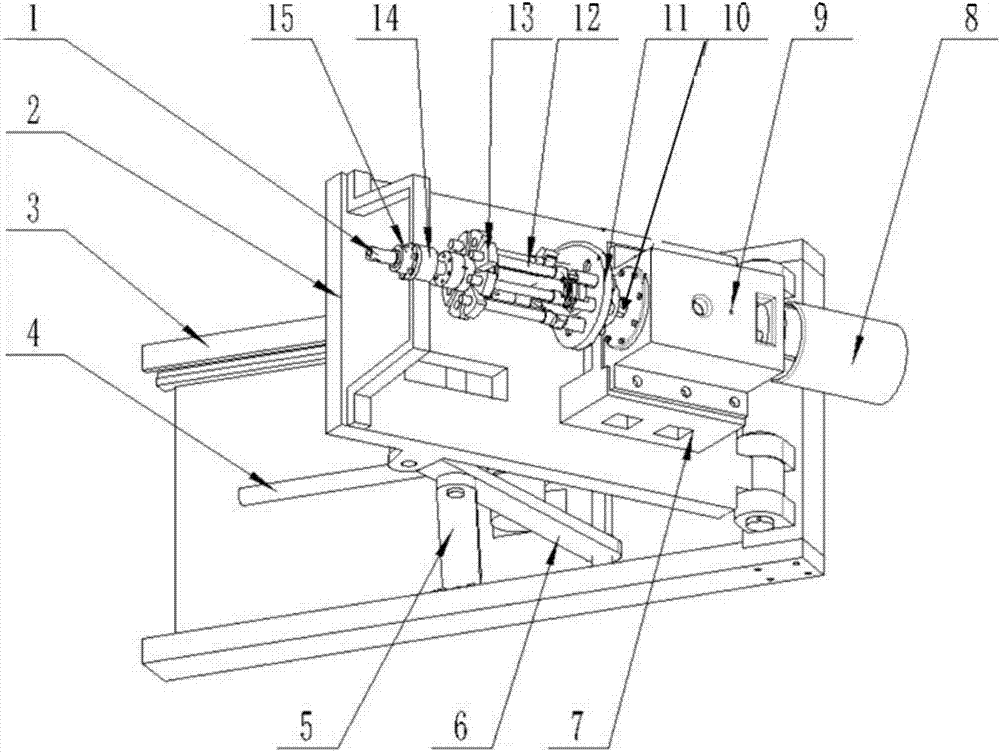

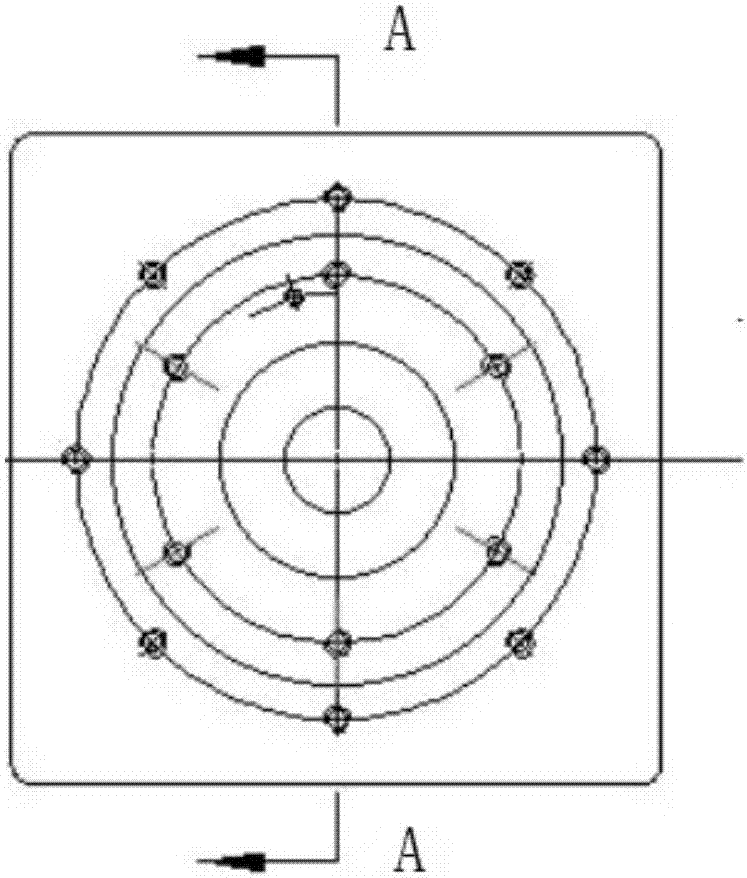

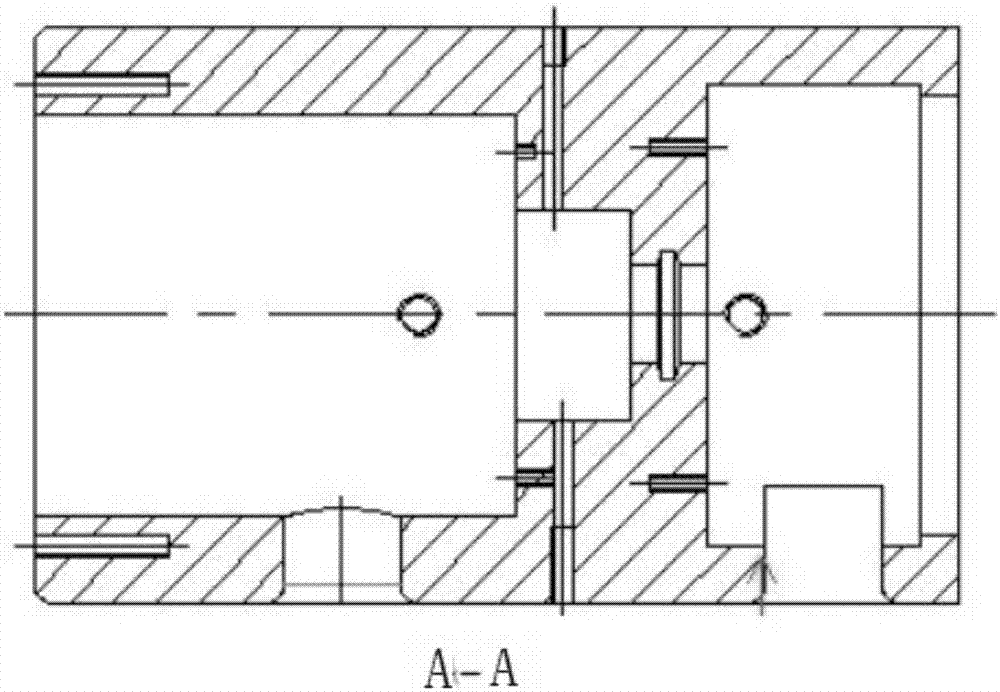

[0041] The utility model relates to a rotary table for testing the expansion of projectile wings under the condition of multi-angle high-speed rotation of projectile bodies, which is composed of a shaft system rotating part, a table body lifting part and a projectile wing locking signal testing device.

[0042]The rotating part of the shaft system includes: hollow shaft 1, variable frequency motor 8, motor base 9, transmission shaft 10, first chuck 11, bracket 12, second chuck 13, bearing seat 14, first multi-way slip ring 15, cone Roller bearing 16, second multi-way slip ring 17, electromagnetic clutch 18;

[0043] The rotating part of the shaft system is powered by the frequency conversion motor 8, the frequency conversion motor shaft and the transmission shaft 10 are connected through the electromagnetic clutch 18, and the control of the start and stop of the entire rotating system is realized by controlling the electromagnetic clutch. Two tapered roller bearings are placed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com