Epitaxial wafer for gallium-nitride-based light emitting diode, and preparation method for epitaxial wafer

A light-emitting diode, gallium nitride-based technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing the luminous efficiency of light-emitting diodes, and achieve the effects of improving energy band matching, increasing luminous efficiency, and enhancing electrical contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

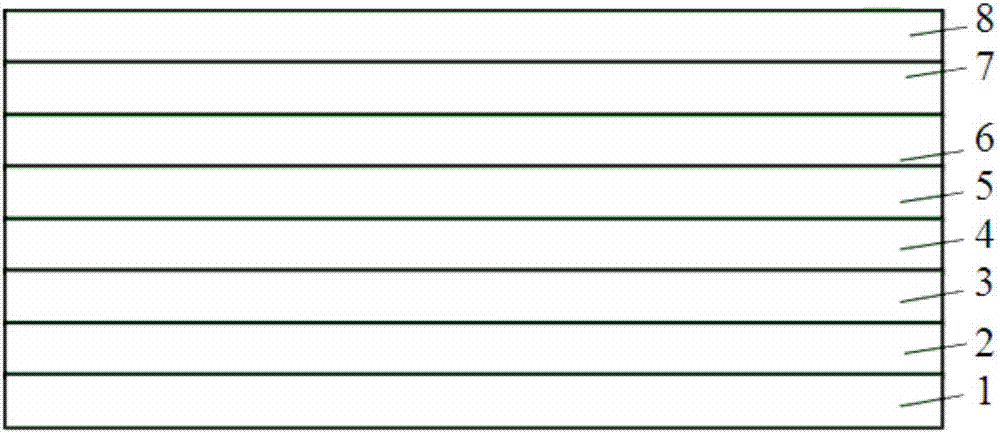

[0026] An embodiment of the present invention provides an epitaxial wafer of a gallium nitride-based light-emitting diode, see figure 1 , the epitaxial wafer includes a sapphire substrate 1, and a GaN buffer layer 2, an undoped GaN layer 3, an N-type GaN layer 4, a multiple quantum well layer 5, a P-type AlGaN layer 6, P-type layer 7.

[0027] In this embodiment, the P-type layer is formed by alternately stacking P-type GaN layers and graphene film layers.

[0028] Optionally, the thickness of the P-type GaN layer is 2-50nm, and adopting an appropriate thickness range can improve the transmission of activated holes and injection into the multi-quantum well layer, and reduce the loss of holes due to relaxation in the P-type GaN layer, The effective output of holes is improved, thereby increasing the number of holes injected into the multi-quantum well layer, and finally improving the luminous efficiency of the light-emitting diode.

[0029] Optionally, the number of graphene ...

Embodiment 2

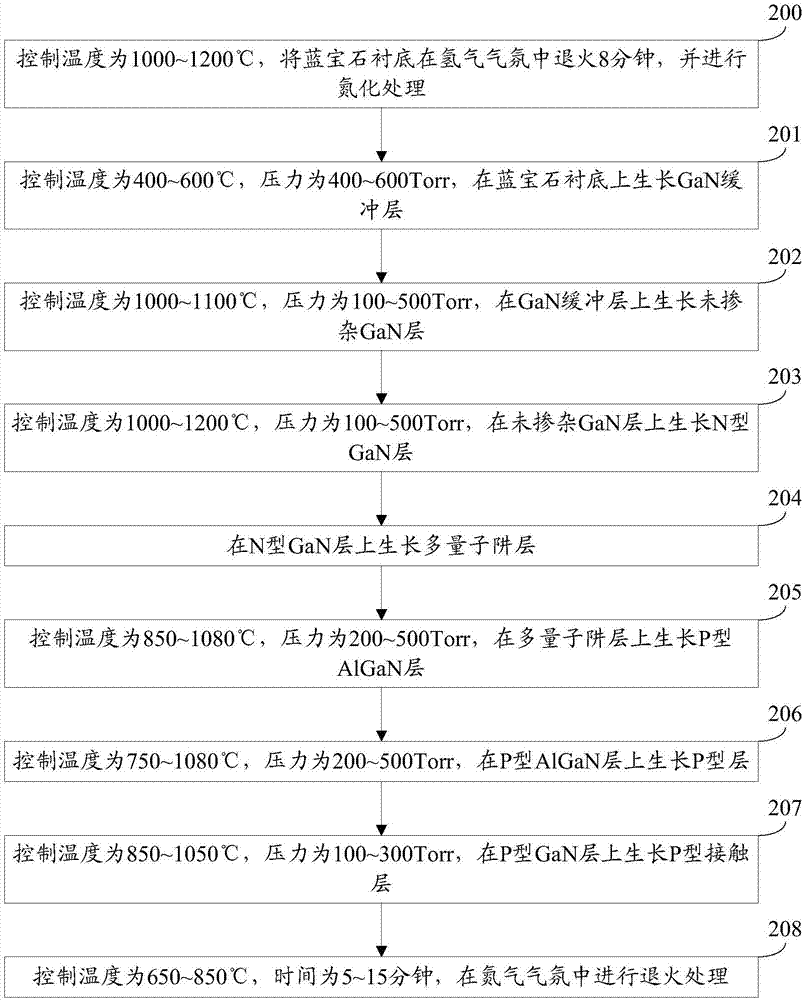

[0044] An embodiment of the present invention provides a method for preparing an epitaxial wafer of a gallium nitride-based light-emitting diode, which is suitable for preparing the epitaxial wafer provided in Embodiment 1. See figure 2 , the preparation method comprises:

[0045] Step 200: Control the temperature to 1000-1200° C., anneal the sapphire substrate in a hydrogen atmosphere for 8 minutes, and perform nitriding treatment.

[0046] Understandably, step 200 can clean the surface of the sapphire substrate.

[0047] In this embodiment, the sapphire substrate 1 adopts (0001) crystal orientation sapphire.

[0048] Step 201: Control the temperature to 400-600° C. and the pressure to 400-600 Torr to grow a GaN buffer layer on the sapphire substrate.

[0049] Optionally, the thickness of the GaN buffer layer may be 15-35 nm.

[0050] Optionally, after step 201, the preparation method may further include:

[0051] The control temperature is 1000-1200° C., the pressure is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Growth temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com